What does MRL stand for?

MRL stands for Machine Room Less Elevator, a modern elevator system that does not need a separate machine room. Instead, the motor and control system are integrated into the top of the elevator car or inside the hoistway. While MRL elevators might seem complex, they are easier to understand than you might think. Let’s break down the basics.

In this article, you will learn about:

-

What a Machine Room Less (MRL) elevator is

-

Components that make up an MRL elevator

-

How MRL elevators work

-

Advantages and disadvantages of MRL elevators

-

MRL elevator codes and standards

-

Which MRL elevator is right for you

-

How much a new MRL elevator costs

-

How to install an MRL elevator

-

How to find a reputable MRL elevator company near you

-

Other MRL elevator guides

-

Why you can trust us

Let’s get started.

What does MRL Elevator mean?

MRL stands for Machine Room Less. Unlike traditional elevators that need a separate machine room to house motors and control equipment, MRL elevators integrate the motor and control system within the hoistway itself or on top of the car. This design saves valuable space and is particularly useful in modern buildings where floor area is at a premium.

A residential MRL elevator is a complete vertical transportation system that can move passengers or goods efficiently while minimizing noise and space usage. Many types of MRL elevators exist, including traction-based and hydraulic-assisted designs.

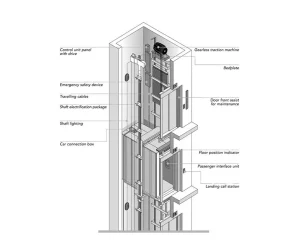

What are the components that make up an MRL elevator?

A complete MRL elevator system has many components working together, both inside and outside the hoistway, to ensure smooth, safe, and efficient operation. While many components can be part of an MRL system, below are the ones you’re most likely to encounter, along with what they do:

Elevator Car

The elevator car is where passengers or goods ride up and down. In an MRL elevator, the car is engineered for a smooth, quiet ride, minimizing vibrations and jolts. Regular maintenance ensures it continues to operate safely and efficiently.

MRL elevator cars come in a variety of sizes and finishes—from sleek steel to transparent glass—so you can match your building’s style while meeting your capacity needs.

Hoistway

The hoistway is the vertical shaft that guides the elevator. Unlike traditional elevators that need a separate machine room, MRL elevators have the motor and control systems integrated directly in the hoistway or on top of the car. Proper preparation of the shaft is key to smooth and safe operation.

Different buildings may need slightly different hoistway setups, especially in older constructions or tight spaces.

Traction Machine

The traction machine, or motor, is what moves the elevator up and down. In an MRL design, the motor is compactly placed inside the hoistway, which saves a lot of building space.

Traction machines can be AC or DC powered, and many feature energy-saving technology that reduces electricity consumption while keeping rides smooth.

Counterweight System

Counterweights balance the elevator car, reducing the energy needed to lift and lower it. This not only saves electricity but also makes rides feel more stable.

Getting the counterweight properly calibrated is crucial for efficiency and safety, particularly in taller buildings with many floors.

Control System

The control system acts as the brain of the elevator. It tells the motor when to start, stop, or slow down, and constantly monitors safety parameters.

Modern MRL elevators often include smart control panels, allowing technicians to diagnose issues remotely and check the system in real-time.

Safety Devices

Safety devices cover emergency brakes, overspeed governors, door locks, and buffers. They work together to ensure passengers are safe, constantly checking speed, position, and door status.

Without these safety mechanisms, even a well-maintained MRL elevator could pose risks—so regular inspections are a must.

Call Buttons and Displays

Call buttons and display panels let passengers select floors and track elevator status. Many newer MRL elevators also support touchscreen panels or smartphone apps, giving users more control and information at their fingertips.

How Machine Room Less Elevators Work

The main job of an MRL (Machine Room-Less) elevator is to move people safely and smoothly between floors while using less space in a building. To do this, the system is built with an elevator car, a traction machine, a counterweight, a control system, safety parts, and a hoistway (the shaft where the car moves).

When the elevator is installed and ready, it reacts right away to your commands. If someone presses a button in the hallway or inside the car, the control system tells the traction machine to move the car up or down. The counterweight balances the car, so the motor does not have to work as hard. This makes the ride smoother and saves energy.

The car travels along rails inside the hoistway. Safety devices check the speed, doors, and position of the car all the time. If something goes wrong, the elevator will stop right away to protect passengers.

Most MRL elevators run on electricity. Many modern ones use energy-saving motors or special drives that can even send power back into the building’s system. Unlike older elevators that need a separate machine room, MRL elevators keep all the main parts inside the hoistway or on top of the car. This design saves space but still provides strong performance and safety.

Advantages and Disadvantages of MRL Elevators

Advantages

-

Saves space: MRL elevators do not need a separate machine room. This leaves more usable space in the building, which is helpful in homes, offices, and modern apartments.

-

Energy efficient: Many models use special motors or drives that use less electricity and can even send power back to the building’s system. This helps lower energy costs over time.

-

Quiet and smooth: Because the traction machine and controls are built into the shaft, MRL elevators usually make less noise and give riders a smoother trip.

-

Smart controls: Some MRL systems include smart features like remote checks and monitoring. This helps building managers find and fix problems faster.

Disadvantages

-

Harder to install: Since the motor and controls are inside the shaft, it can be tricky to install, especially in older buildings.

-

Higher starting cost: Buying and installing an MRL elevator can cost more than a traditional one because of its compact motors and smart technology.

-

Tighter for repairs: With everything inside the shaft, repair crews have less room to work. This means the system needs careful planning during setup and sometimes more frequent checks.

MRL elevators save space, use less energy, and run quietly. But they can cost more at first and be harder to install or maintain. Building owners should think about both the short-term costs and the long-term benefits.

Codes and Standards for Machine Room Less Elevators

MRL elevators must follow international safety codes, such as:

-

EN 81-20/50 (Europe)

-

ASME A17.1/CSA B44 (North America)

These standards define requirements for design, safety devices, clearances, and testing.

Which Machine Room Less Elevators Is Right for You?

The right MRL elevator for your project depends on several things, such as the type of building, the number of people or goods it needs to carry, and how many floors it must travel. For example, a residential or commercial building may only need a standard passenger elevator, while a hotel or hospital may need larger capacity and special features.

You should also think about your goals. Do you want to save as much space as possible? Are you focused on energy efficiency or meeting green building standards? Or do you need an elevator that can handle heavy freight? These preferences will help decide the best model for your needs.

Once you know what matters most, the next step is to speak with a trusted elevator company. A professional can explain your options, match them to your building requirements, and guide you toward the system that works best. The first step to choosing the right MRL elevator is simply learning how they work—which means you’re already on the right path.

How much does a new Machine Room Less Elevators cost?

Your MRL elevator cost will vary, depending on several factors, including:

-

The type of elevator (passenger, freight, panoramic/glass, hospital/bed)

-

Capacity and car size (e.g., 630–1600 kg for passenger)

-

Number of stops and speed

-

Building location and local pricing

-

New build vs. retrofit work in an existing shaft

-

Required electrical upgrades (power, breakers, wiring)

-

Door type and openings (center-opening, side-opening, door width/height)

-

Interior finishes (standard vs. luxury)

-

Code, seismic, and fire-service requirements

-

The brand you choose

-

Who you hire to install and service it

There are also specific cost factors related to the type of MRL elevator.

Passenger MRL cost

How much is a new passenger MRL? It depends. Passenger MRL pricing will vary based on:

-

Capacity and car size (e.g., 630–1600 kg)

-

Number of stops (mid-rise is often 6–20 floors)

-

Speed and traffic needs

-

Door configuration and door width

-

Interior finishes (standard vs. premium)

A typical mid-rise passenger MRL (about 6–8 stops) often falls around $40,000–$60,000. Your cost will be higher if major shaft changes or electrical upgrades are needed.

Freight/Service MRL cost

How much does a freight or service MRL cost? Again, it depends on your use case. Costs will vary based on:

-

Heavy-duty components and door protection

-

Larger car sizes and higher capacities

-

Duty cycle (how often it runs each day)

-

Floor loading and building structure support

-

Special controls for back-of-house logistics

Freight and heavy-duty systems commonly range $70,000–$120,000+, depending on size and protection needs.

Panoramic/Glass MRL cost

How much does a panoramic (glass) MRL cost? The answer depends on design choices. Pricing changes with:

-

Glass walls and frame system

-

Custom car finishes and lighting

-

Structural supports for the hoistway

-

Wind, weather, or public-space requirements

-

Custom controls and aesthetics

Because of custom glass and structure, many projects start at $150,000 and above.

Hospital/Bed MRL cost

How much does a hospital or bed MRL cost? It depends on medical needs. Costs vary with:

-

Car size to fit a stretcher and staff

-

Wider doors and precise leveling

-

Standby power and fire service modes

-

Infection-control finishes (stainless steel, easy-clean panels)

-

Higher duty cycle and reliability targets

Larger sizes and added features typically place these systems in a higher range (often overlapping $80,000–$130,000+ depending on specs).

Other cost factors to keep in mind

Your total cost may be higher if this is a new installation in a finished building that requires zoning, shaft construction, cutting openings, new power feeds, or structural reinforcement. Service plans and long-term maintenance contracts also affect lifetime cost. Over time, you may consider modernization (controls, doors, interiors) to extend service life.

Tip: Consider energy-efficient options like gearless PM machines and regenerative drives. In some regions, these may earn green-building points and reduce electricity costs over the years.

For specific pricing in your area and a proposal matched to your drawings, contact a trusted elevator supplier or BDFUJI Elevator. An expert can review your plans and provide a detailed, project-ready quote.

How to Install a Machine Room-Less Elevator

If you are not a trained elevator worker, you should not try to install a machine room-less (MRL) elevator. This job must be done by licensed professionals who know the safety rules and building codes. Doing it yourself without the right skills can be dangerous and may even cancel the elevator manufacturer’s warranty.

The installation steps can change based on the type of MRL elevator and the building. In most projects, workers build the hoistway and pit to the correct size, put in the guide rails and counterweight, place the motor and controller inside the shaft, and assemble the cabin. Then they connect the ropes, finish the electrical wiring, and set up the control system.

Before anyone can ride the elevator, it must pass safety checks, load tests, and inspections for approval.

MRL Elevator Installation Timeline

The installation timeline for an MRL elevator depends on the project size and building type. For a mid-rise home or office, installation usually takes about 2–3 months. Bigger projects—like hospital or freight elevators—may take 4 months or more, especially if the building needs extra structural work or electrical upgrades.

How to Find the Right MRL Elevator Company

Choosing the right MRL (machine room-less) elevator company is one of the most important steps in your building project. Even the best design will not succeed if the equipment itself is unreliable. That’s why it’s important to find a supplier you can trust for quality elevators that meet your project’s requirements.

Start by asking contractors, architects, or building owners which elevator brands they recommend and which suppliers they trust. Look for companies with a strong record of delivering elevators for residential, commercial, hotel, or hospital projects.

Research potential suppliers carefully. Visit their websites, read customer feedback, and check for certifications such as ISO, CE, or local safety approvals. Pay attention to whether the company can provide the right capacity, speed, and design options for your project.

If your project involves glass elevators, hospital bed elevators, or high-capacity freight elevators, make sure the supplier has proven experience with those types. Request detailed specifications and clear quotations so you can compare options fairly.

The right MRL elevator company will give you reliable equipment, on-time delivery, and strong technical support, helping your project run smoothly from planning to final installation.

Other Guides on MRL Elevators

Mrl Elevator vs Traction Elevator: Was sind ihre Unterschiede?

Why You Can Trust Us

When we share information about elevators, our goal is to help builders, contractors, and property owners make informed choices. We work closely with elevator engineers and industry professionals who have many years of experience. All our guides and resources are reviewed for accuracy so you get clear, reliable, and up-to-date information.

Since 2011, BDFUJI Elevator has focused on designing and manufacturing safe, efficient, and modern elevators, including machine room-less (MRL) systems, panoramic glass elevators, freight elevators, and residential lifts. Our factory in China, Suzhou produces over 1,500 units a year, with strict quality control and international certifications such as CE and ISO 9001/14001.

We are trusted worldwide by distributors, contractors, and OEM/ODM partners who value our ability to deliver high-quality products on time.

Explore our full product range: Passenger Elevators, Residential Elevators, Glass Elevators, Freight Elevators, and Customized OEM/ODM Solutions.

MRL Elevators FAQ

How fast are MRL elevators?

MRL elevators typically have speeds ranging from 200 feet per minute (fpm) to 500 fpm, which is suitable for mid-rise buildings. They are generally slower than high-speed traditional elevators but efficient for their purpose.

Which is better, MRL elevators or elevators with machine rooms?

MRL elevators are better for buildings with limited space, where a machine room cannot be installed. They are more compact, quieter, and cost-effective. However, traditional elevators are better suited for high-rise buildings, as they can handle heavier loads and travel longer distances more efficiently.

How to Cool a Machine Room-Less Elevator?

A machine room-less (MRL) elevator keeps its motor and controller inside the hoistway instead of in a separate machine room. Because of this design, heat can build up if the shaft is not well ventilated. The best way to keep an MRL elevator cool is to make sure the hoistway has good airflow, either through vents or small fans that move air in and out of the shaft.

Where is the operating equipment for an MRL elevator located?

The operating equipment for an MRL (Machine Room-Less) elevator is located inside the elevator shaft. Unlike regular elevators, MRL elevators don’t need a separate machine room. Instead, the motor and control systems are placed inside the shaft, usually above the elevator car or next to it. This saves space in the building.