Choosing the right elevator can be confusing. There are many types, but not all are built for high speed or heavy loads.

If an elevator is too slow or uses too much power, tenants will complain, and owners will face higher costs. This problem is even worse when the lift is not a traction lift.

A traction lift is the most common type of elevator in the world. It offers both comfort and performance. In this article, we will explain traction lifts in simple words—how they work, their parts, types, and costs.

What is a Traction Lift?

A traction lift is an elevator driven by an electric traction machine.

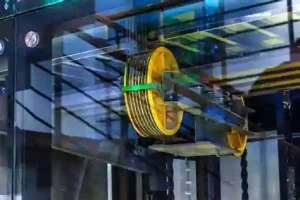

The machine turns a grooved wheel called the traction sheave, and steel ropes loop over this wheel. One end of the ropes connects to the cab, the other end to a counterweight. When the motor rotates the sheave, the counterweight moves down as the cab moves up, or vice versa.

The weight balance means the motor only provides enough power to overcome friction and passenger load, not the full weight of the cab. This makes traction lifts faster, more energy‑efficient, and capable of serving medium‑ and high‑rise buildings, often reaching speeds above 2.5 m/s and handling heavy passenger flows reliably.

When Was the First Traction Lift Invented?

The first traction lift was built in 1903 by the Otis Elevator Company. It was installed in the Beaver Building, a 15‑story office tower in Manhattan. Records from Otis and the Skyscraper Museum in New York confirm this.

At that time, New York’s tall buildings were growing fast, but hydraulic elevators could not go high or fast enough. The new rope‑and‑sheave design fixed these problems, and within ten years, trade journals like Engineering News called traction lifts the new standard for skyscrapers.

How Does a Traction Elevator Work?

A traction Elevator works like this: the cab and a counterweight are connected by strong steel ropes that pass over a grooved wheel called a sheave.

When the electric motor turns the sheave, the ropes move. If the cab goes up, the counterweight goes down, and the other way around. This balance means the motor does not have to lift the full weight of the cab—only the difference in weight. Imagine a simple pulley with two sides: one side has the elevator cab, the other side has a heavy counterweight. When the motor turns the pulley, the counterweight helps lift the cab up, and when the cab goes down, it helps pull the counterweight back up.

This picture makes it easier to see how the system saves energy and moves smoothly. This system makes the lift smoother, faster, and less power-hungry.

What Parts Make Up a Traction Lift?

Looking inside a traction lift shows that it is made of several key parts, each with an important job in moving the cab safely and smoothly.

- Traction machine: Usually placed at the top of the shaft, in a machine room or overhead space. It is an electric motor that spins the traction sheave, the grooved wheel that moves the ropes. Without this motor, the cab cannot move.

- Steel ropes: These run vertically through the shaft, looping over the sheave at the top. One end holds the cab in the shaft, the other end holds the counterweight. They are made of steel wires twisted together for strength.

- Counterweight: Located in the shaft beside the cab. It travels up and down on its own set of guide rails. Its weight equals the empty cab plus half the passenger load, which reduces the motor’s effort.

- Guide rails: Long steel tracks fixed to the shaft walls. One set guides the cab, another set guides the counterweight. They keep both moving straight up and down without swaying.

- Control system: Usually in a control cabinet near the machine or in the shaft. It is the “brain” of the lift, receiving signals from floor buttons, telling the motor when to run, controlling door movements, and stopping the cab level with the floor.

What Types of Traction Lifts Are There?

Traction lifts are grouped into a few main types, each defined by its design and use.

From geared to gearless to machine-room-less models, every type offers special advantages and fits different building needs.

Geared Traction Lift

This type uses an electric motor connected to a gearbox, which then turns the traction sheave. Because of the gearbox, it usually runs at lower speeds, around 0.5 to 1.75 meters per second. Geared lifts are most often installed in mid‑rise buildings such as offices or residential towers with up to about 20 floors.

Gearless Traction Lift

Gearless traction lifts move faster because they do not use a gearbox. Instead, the motor connects straight to the traction sheave, which makes the ride smoother and the system simpler. They usually run at speeds of 2.5 to 10 meters per second, so they are common in tall office towers and skyscrapers. Although they cost more than geared lifts, they are the only practical choice when a building needs both high speed and long travel distance.

MRL (Machine-Room-Less traction lift)

In this type, there is no separate machine room above the shaft. Instead, the motor and control equipment are placed inside the shaft itself, often mounted near the top beside the guide rails. This saves valuable roof or floor space and reduces construction costs. MRL lifts usually run at speeds of 1 to 2.5 meters per second, making them suitable for residential buildings, offices, and small commercial projects up to about 20 floors. Because they free up building space and still provide reliable performance, many modern developers choose them. For example, BDFUJI’s MRL traction lifts are often selected in urban projects where every square meter matters, giving building owners both energy savings and extra design flexibility.

What Are the Differences Between Traction and Hydraulic Lifts?

Traction and hydraulic lifts are built on very different principles.

Traction lift uses ropes, a sheave, and a counterweight, making it faster and more energy‑efficient, especially in medium‑ to high‑rise buildings. It can reach much higher travel distances and speeds than a hydraulic lift.

By contrast, a hydraulic lift pushes the cab up from below using fluid pressure in a cylinder. This design is simple and cheaper to install but usually limited to low‑rise buildings of 2–6 floors. Hydraulic lifts also consume more power during upward travel and can require more maintenance due to oil leaks and heat in the system.

In short, traction lifts are preferred for tall, busy buildings, while hydraulic lifts remain an option for short, low‑traffic applications.

What Are the Dimensions of a Traction Lift?

Here are common cab dimensions for traction lifts, shown in a simple table:

| Building Type | Typical Width | Typical Depth | Typical Height | Notes |

|---|---|---|---|---|

| Home | ~1 m | ~1 m | ~2 m | Fits 2–3 people |

| Office/Hotel | 1.5–2 m | 1.5–2 m | ~2.3 m | For small groups of passengers |

| Hospital | 2.2–2.5 m | 1.5–2 m | ~2.3 m | Large enough for a stretcher |

| Freight | 2.5 m+ | 2.5 m+ | 2.3–3 m | Built for heavy goods and pallets |

How Much Weight Can a Traction Lift Carry?

Here are common load capacities for traction lifts, shown in a simple table:

| Building Type | Typical Capacity | Notes |

| Home | ~320 kg (4 people) | Enough for a family or a few guests |

| Office/Hotel | 800–1600 kg (10–20 people) | Suitable for groups of passengers |

| Hospital | 1600–2000 kg | Built to carry a stretcher plus staff |

| Freight | 2000–5000+ kg | For heavy goods, pallets, or machinery |

How Much Does a Traction Lift Cost?

When it comes to traction lifts, the cost can vary widely. Prices reflect differences in building height, speed, decoration, and how much customization is required.

Typically, smaller residential traction lifts start around $20,000–$40,000, while larger commercial lifts with advanced features can range from $80,000 to over $200,000. This wide range shows how important it is to understand what factors influence the final price.

Key factors that affect cost include:

- Building height and speed: Taller buildings and faster lifts need stronger motors and more complex systems, which increase cost.

- Cab size and decoration: A simple steel cab is cheaper, while custom finishes, lighting, and design raise the price.

- Technology type: Gearless traction lifts cost more than geared models but give smoother rides and higher speeds.

- Brand and quality: Well‑known manufacturers with high safety standards may charge more but offer better reliability and service.

- Extra features: Energy‑saving drives, smart controls, or earthquake‑resistant designs can add to the cost.

For example, a small residential lift for a two‑story home may fall at the lower end of the spectrum, while a high‑speed gearless traction lift in a skyscraper is a major investment.

How Much Electricity Does a Traction Lift Use?

The energy use of a traction lift depends on how big the cab is, how fast it moves, and how many trips it makes each day.

On average, a traction lift for a small apartment building may consume only a few kilowatt‑hours daily, while a busy office tower lift can use hundreds.

Modern traction lifts often save 30–40% of energy compared to older designs because they use counterweights and efficient motors. A smart control system that adjusts motor output can cut bills even further.

BDFUJI traction lifts go one step further by using energy recovery technology. This system collects energy when the cab goes down with a heavy load or goes up with a light load and sends it back into the building’s grid.

In real use, this can save about 10% more electricity, lowering costs and making the lift more eco‑friendly.

What is the Service Life of a Traction Lift?

A traction lift usually lasts 20–30 years when it is cared for properly, but the exact lifespan depends on many factors.

- Usage: A small lift in an apartment building may last longer because it makes fewer trips each day, while a busy lift in a shopping mall wears out faster.

- Maintenance: Regular service, like checking brakes and lubricating ropes, keeps parts from wearing down too quickly.

- Environment: Lifts in clean, dry buildings often last longer than those in harsh or humid places.

With steady care, many traction lifts stay safe and reliable for decades, giving owners good value over time.

How to Maintain a Traction Lift?

Taking care of a traction lift is very important for safety and long life. Regular service keeps the parts working well and helps avoid sudden breakdowns.

Checklist

- Lubricate steel ropes: Apply rope lubricant along the cables to reduce friction and wear. This makes the ride smoother, quieter, and helps prevent rust. Be careful not to spill lubricant on the traction sheave or brakes.

- Inspect and adjust brakes: Check that the brake pads, springs, and levers work correctly so the cab can stop safely at every floor. If brakes are too loose, the cab may slide; if too tight, they cause noise and wear. So the brakes must be adjusted regularly.

- Test control system: Check that all buttons in the cab and on each floor respond correctly, sensors detect doors and cab position, and signals such as alarms and lights work. This ensures passengers can call the lift and ride safely, and that they can still send an alert if something goes wrong.

- Clean the machine room: Remove dust, dirt, and clutter regularly to protect the motor, ropes, and control panels. A clean machine room keeps air flowing, prevents overheating, and makes it easier for technicians to work safely.

Schedule

- Home lifts: Every 3 months.

- Commercial lifts: Every month, since they run more often and carry more people.

Traction Lift Maintenance Tips

- Hire licensed companies: Always make sure the service provider is certified to perform elevator maintenance. This protects both safety and legal compliance.

- Check service reports: After each maintenance visit, review the written report to confirm what was checked and repaired.

- Schedule inspections: Keep to a clear schedule (monthly for commercial lifts, quarterly for home lifts) and make sure inspections are not skipped.

- Observe performance: If the lift becomes noisy, shakes, or stops unevenly at floors, call for service right away instead of waiting.

How to Choose the Right Traction Lift?

Choosing the right traction lift is one of the most important decisions for a building owner or developer. The right choice means safe, reliable, and cost‑efficient service for many years. The wrong choice can lead to higher bills, delays, and unhappy tenants.

When selecting a traction lift, consider the following points in detail:

Building height and speed needs

The number of floors and the building type directly affect the lift speed required.

For example, a low‑rise apartment (up to about 6–8 floors) may only need a lift that travels at 1 meter per second. A mid‑rise office tower of 10–20 floors might need 1.5–2.5 meters per second.

High‑rise office towers and skyscrapers above 20 floors usually require gearless traction lifts that can run at 2.5–10 meters per second, ensuring passengers move quickly and without long waiting times.

Weight capacity

The number of people or goods a lift must carry each trip is critical.

School might only need a lift for 6–8 people (about 500–630 kg), built for steady but light use. A hospital lift usually needs to fit a stretcher plus staff, so capacities of 1600–2000 kg are common.

Shopping malls or warehouses often require freight lifts rated at 2000–5000+ kg, strong enough to carry pallets, trolleys, or heavy goods every day. Choosing the right capacity prevents overloading, reduces wear, and ensures smooth service.

Budget

Costs vary widely depending on size, speed, and features. For example, a simple home lift may cost $20,000–$40,000, while a high‑speed gearless model for a tall office tower can exceed $200,000.

Owners should compare not only purchase price but also long‑term costs like electricity and maintenance, since these add up over decades.

Where to Buy Affordable Traction Lifts?

When it comes to buying a traction lift, you have many options. Leading international brands such as Otis, Schindler, KONE, Thyssenkrupp, and Mitsubishi, as well as strong regional manufacturers, provide models for different building needs—from small residential lifts to high-speed skyscraper solutions.

You can purchase directly from manufacturers, work through certified distributors, or consider second-hand lifts for more budget-friendly projects.

Trusted suppliers should always provide proof that their lifts meet national or international standards, such as EN 81 or ASME A17.1. In addition, it is important to confirm that they can supply spare parts, offer 24/7 emergency repair, and provide long-term service contracts.

Industry trade shows, online platforms, and professional dealer networks can also help compare models, features, and prices. If you are not ready to invest in a big international brand or prefer a cost‑effective alternative, BDFUJI provides traction lifts that combine safety, energy efficiency, and affordability—making them a practical choice for many different projects.

Conclusion

Traction lifts are the backbone of modern vertical transport. They are efficient, safe, and long-lasting. If you are considering a new lift, remember that different projects have different needs—whether it is a small residential building or a busy high-rise. Compare your options carefully, look at speed, capacity, and cost, and choose a trusted supplier.