If you’ve ever walked through a mall, airport, or metro station, you’ve probably used an escalator—but what exactly is it? Escalator is a moving staircase powered by an electric motor and chain system . Instead of stopping to wait for an elevator or climbing long staircases, passengers can step on and be transported continuously.

Compared to stairs, they can handle thousands of passengers per hour, reduce congestion, and make buildings more accessible. Plus, with different types,straight, crisscross, spiral, and even outdoor models—escalators can adapt to a wide range of architectural designs and traffic needs.

This flexibility makes escalators a core part of modern infrastructure.

In this article, we’ll focus on how escalators work, the different types of escalators, their pros and cons, and their prices.

What is an Escalator?

Escalators are moving stairways powered by electric motors and chain-driven step systems.The system operates through steps linked together in a closed loop, circulating around gears and supported by a truss structure. Handrails move in sync with the steps, while safety devices—such as emergency stop switches, step demarcation lines, and anti-slip designs—help ensure passenger safety. Escalators are especially effective in handling peak-hour traffic, moving thousands of people per hour with minimal waiting time.

Different types of escalators serve different architectural and operational needs. Straight configurations are common in department stores and transit hubs, crisscross layouts save space in multi-level malls, while spiral or curved models provide both functionality and visual appeal in unique building designs. Outdoor escalators, built with weather-resistant materials and sealed electrical systems, extend accessibility to open-air environments.

With proper design, installation, and maintenance, escalators not only streamline vertical transportation but also become integral to the overall efficiency and safety of modern buildings.

How The Escalator Works?

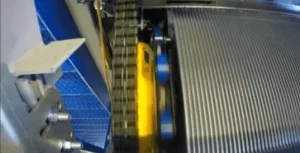

An escalator works through a combination of electric motors, gears, and chain-driven tracks that keep the steps moving in a continuous loop. At each end of the escalator, large gears are connected by chains, similar to a bicycle system, and powered by a drive motor. As the gears rotate, they pull the step chain along the track, ensuring that the steps rise smoothly at one end and descend at the other.

The steps themselves are mounted on rollers that slide along guide tracks on both sides of the truss. This track design is critical—it keeps the treads level for passengers while allowing the risers to fold beneath as the steps cycle back underneath. Above the steps, a handrail system runs in sync with the moving staircase, driven by a separate belt and pulley system so that passengers can hold on without losing balance.

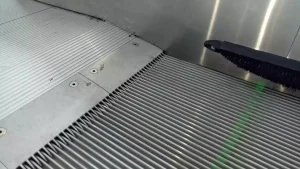

At the boarding and landing points, comb plates with interlocking teeth meet the grooves of the steps. These plates not only reduce tripping hazards but also help clear dirt and debris from the step surface before it cycles into the machinery. Combined with other safety devices—like emergency stop buttons, step demarcation lines, and automatic braking—the system ensures both reliability and passenger protection.

Once steps complete their journey at the top or bottom, they collapse back into a flat chain hidden inside the truss and loop around to begin the cycle again.

What Does The Inside of an Escalator Look Like

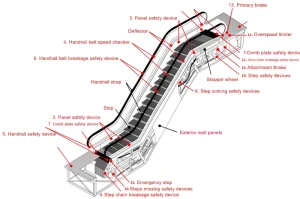

An escalator is more than just the moving steps you see—it’s a complex machine made up of multiple systems working in sync to provide safe, continuous passenger transport. Each subsystem has a specific role, from driving the steps to ensuring safety and smooth operation. Let’s take a closer look inside.

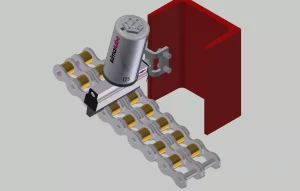

Driving Device

The driving device provides the power to move both the step chain and the handrail. At the heart of this system is the electric motor, usually designed for high torque to handle heavy loads during start-up. The motor connects to a reducer—most commonly a worm gear design—that lowers speed while increasing torque for smoother operation. A working brake, mounted on the high-speed shaft, allows the escalator to stop safely when needed. Transmission is typically achieved through double-row chain drives, known for their durability in continuous service. Finally, the drive spindle acts as the hub, supporting the step drive sprockets and handrail drive wheels, and often houses an emergency brake for additional protection.

Stairway

The stairway is the moving pathway that passengers step onto. It is composed of individual steps linked by conveyor chains and guided by rails that keep the treads level as they circulate. Each step is designed with a metal shell rather than solid metal, reducing weight while maintaining strength.

The triangular geometry of the step allows them to neatly nest together as they rotate around the upper and lower turning points. This triangular design forms a smooth curve from incline to flat sections and prevents steps from jamming at the transition. Standard step widths range from about 580 to 1100 mm, providing flexibility for different passenger capacities. The conveyor chain, often a sleeve roller design, must maintain extremely tight tolerances so that paired chains remain synchronized, minimizing vibration and wear over long service cycles.

Handrail Device

The handrail device ensures that passengers can ride securely, with the belt moving in sync with the steps. It consists of the rubber handrail belt, friction drive components, breakage protection devices, apron plates, and decorative panels. To meet safety codes, the handrail height from the step surface is maintained between 900 and 1100 mm, and the speed deviation between the handrail and steps must remain within +2%. The breaking load of the handrail belt must reach at least 25 kN, or else a belt-breaking stop device must be installed. Glass balustrades, when used, are tempered with a minimum thickness of 6 mm to resist impact.

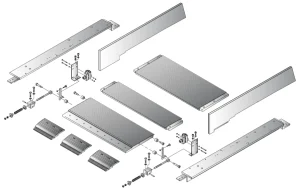

Truss

The truss forms the structural backbone of the escalator. Constructed from angle steel or square tubing, it supports the entire weight of the machinery and passengers while transferring loads to the building structure. In large public transportation escalators, intermediate supports are added along the incline to control deflection and keep it within standard limits. Without this rigid skeleton, the precision alignment of the drive and stairway systems would not be possible.

Cover Plate Assembly

Located at the entry and exit zones, the cover plate assembly bridges the stationary floor with the moving steps. Comb plates, with teeth that interlock with the grooves of each step, serve two roles: providing a safe transfer point for passengers and cleaning debris off the step surface before it cycles into the machinery.

Lubrication System

To handle continuous operation, escalators employ an automatic lubrication system. Oil pumps, reservoirs, and nozzles deliver controlled amounts of lubricant to the main drive chain, the step chain, and the handrail drive. Proper lubrication minimizes friction, reduces wear, and extends service life—an essential factor in equipment designed to run up to 20 hours a day.

Safety Devices

Escalators incorporate a wide range of safety devices to meet standards such as EN 115 and ASME A17.1. These include emergency stop buttons, step sag sensors, skirt panel protection, handrail speed monitors, and drive chain breakage detectors. For example, if the main chain elongates beyond safe limits, the protection switch cuts power to the drive system and halts operation immediately. Together, these safeguards ensure that escalators remain one of the safest forms of mass transportation in modern buildings.

How Escalators are Installed

Escalators are different from regular elevators. They do not need to be built piece by piece on site. Instead, they are shipped from the factory as complete units. Some buildings even make a hole in the ceiling so the escalator can be lifted into its final position.

Typical Escalator Installation Process:

Design review & drawing preparation → Delivery and positioning of the escalator truss → Site preparation → Surveying & alignment → Fixing the steel truss frame → Installation of metal cladding panels → Edge finishing & detailing → Testing, commissioning & self-inspection.

For detailed installation methods and layout requirements, please refer to the Escalator Installation Guide.

Types of Escalators

Escalators can be classified in several ways, most commonly by their functional purpose or by their exterior design. Each type serves a unique role in handling passenger flow and adapting to architectural requirements.

Straight Escalators

Straight escalators are the most common form and are widely installed in shopping malls, supermarkets, metro stations, and airports. They provide stable operation, high safety, and broad adaptability across different building layouts. Their straightforward design makes them cost-effective to install and maintain while still handling thousands of passengers per hour.

Spiral Escalators

Spiral escalators are designed for spaces that emphasize aesthetics or architectural impact, such as exhibition halls, luxury malls, or iconic commercial centers. Their curved layout creates a striking visual effect and maximizes design flexibility in unconventional spaces. However, these systems come at a higher cost and require more complex maintenance due to their specialized track and step design.

Moving Walkways (Automatic Walks)

Moving walkways are horizontal or slightly inclined conveyor systems, often found in airports, supermarkets, and long corridors. They are ideal for transporting large volumes of passengers or luggage over extended distances but are not suitable for steep vertical elevation. With flat or near-flat step profiles, they enhance efficiency in environments where speed and accessibility matter more than height differences.

Outdoor Escalators

Outdoor escalators are engineered to withstand environmental exposure such as rain, dust, and temperature fluctuations. They are commonly used in open-air transit stations, overpasses, and shopping districts to improve accessibility between street levels. With weather-resistant materials, sealed electrical systems, and enhanced drainage, outdoor escalators deliver reliable performance in challenging conditions while maintaining passenger safety.

Escalator Costs in the World

The cost of installing an escalator varies widely across regions and project types, depending on specifications, site conditions, and safety requirements.

Globally, the average price of escalators is as follows:

- Small straight escalator: $10,000.

- Medium curved escalator: $50,000.

- Large spiral escalator : $1 million.

Of course, these prices are approximate and may vary depending on the factors mentioned above. It is important to obtain quotes from different companies before purchasing an escalator. Contact BDFUJI now to find out the costs of the escalator that is right for you.

Factors Affecting Escalator Costs

Factors Affecting Escalator Costs

Several key factors determine the total cost of purchasing and installing an escalator. Base equipment prices vary by size, step width, and intended application—smaller residential escalators can start around $10,000, while large, custom spiral escalators in airports may exceed $1 million. Beyond equipment, civil construction, installation labor, and long-term maintenance also play major roles in shaping overall investment.

Equipment Specifications

The design and dimensions of the escalator directly influence its price. Standard straight escalators with 600–800 mm steps are typically the most affordable, while wide 1,000 mm steps, outdoor weatherproofing, or energy-efficient drives increase costs. Options such as glass balustrades, stainless steel finishes, and advanced safety features also add premiums, especially in high-end commercial or transport projects.

Installation and Civil Works

Site preparation and installation are major cost drivers. Structural supports, pits, electrical cabling, and drainage must meet international safety codes. Projects in urban centers often see installation costs rise due to higher labor rates and stricter compliance requirements. Outdoor escalators require reinforced trusses, waterproofing, and anti-corrosion treatments, all of which add to civil works budgets.

Maintenance and Lifecycle Costs

Long-term ownership costs are just as important as purchase price. Annual maintenance contracts usually range from $2,500 to $5,000 per unit, depending on service frequency and regional pricing. Spare parts, periodic overhauls, and energy consumption contribute further to lifecycle costs. Escalators in metro systems or airports, where they operate 18–20 hours a day, demand higher service levels compared to retail installations.

Production Volume and Procurement

Large-scale projects benefit from economies of scale. For example, metro networks or airport expansions that purchase dozens of units at once can negotiate significantly lower per-unit pricing. Conversely, single-unit residential or small commercial installations tend to be more expensive per escalator due to limited procurement leverage.

Labor and Regional Differences

Labor costs vary widely across regions. In North America and Europe, escalator installation tends to be more expensive due to higher wages and strict regulations. In Asia, particularly China, manufacturers can often supply more competitively priced equipment, but logistics, tariffs, and after-sales service availability must be considered.

Escalator Main Parameters

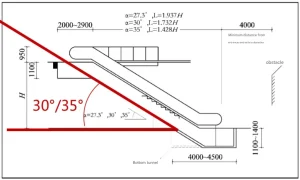

The three most important parameters in escalator design are vertical rise, inclination angle, and running speed. These directly influence passenger capacity, ride comfort, and overall safety performance. Beyond this key trio, escalator design also depends on additional variables such as step width, horizontal steps, and curvature radius. Together, these parameters ensure that the escalator can operate smoothly, handle heavy traffic, and comply with international standards. Below are the crucial parameters you should evaluate and control for every project:

Vertical Rise (Rise Height)

Vertical rise refers to the total height an escalator covers between two floors. Small escalators typically have a rise of less than 6 meters, medium escalators span 6–20 meters, and large escalators can exceed 20 meters. The chosen height directly affects structural requirements, power consumption, and cost.

Inclination Angle

The inclination angle is one of the defining parameters of escalator design. Standard values include 35°, 30°, 27.3°, and 23.2°. For escalators with a rise of ≤6 m and a speed ≤0.5 m/s, the maximum allowed angle is 35°. Lower inclination angles are often preferred for improved comfort and safety.

Running Speed

Speed regulations link closely to inclination. When the angle is greater than 30°, the maximum speed is limited to 0.5 m/s. At angles of 30° or less, speeds can reach up to 0.75 m/s. These restrictions balance efficiency with rider stability, especially in public transit applications.

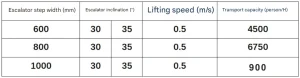

Step Width

Step width defines passenger capacity. Standard dimensions are 600 mm, 800 mm, and 1000 mm, but actual values range from 580 to 1100 mm. Step depth should be at least 380 mm, and step height should not exceed 240 mm. Wider steps support higher throughput but require greater structural space.

Horizontal Steps

Horizontal steps provide safe boarding and exiting zones. Their number depends on rise height and speed:

K type: 2 steps for H ≤ 6 m and V ≤ 0.5 m/s.

M type: 3 steps for H > 6 m or 0.5 < V ≤ 0.65 m/s.

L type: 4 steps for H > 6 m and V > 0.65 m/s.

National standards require a horizontal section length of at least 800 mm, equivalent to two steps.

Radius of Curvature

The curvature radius at the upper and lower ends ensures smooth transitions. Requirements vary with speed:

For V ≤ 0.5 m/s: upper ≥ 1.0 m, lower ≥ 1.0 m.

For 0.5 < V ≤ 0.65 m/s: upper ≥ 1.5 m, lower ≥ 1.0 m.

For 0.65 < V ≤ 0.75 m/s: upper ≥ 2.6 m, lower ≥ 2.0 m.

These values prevent excessive acceleration or discomfort when passengers step on or off, while also reducing wear on the step chain and tracks.

What are the Main Advantages of Escalators

Escalators provide a range of advantages that make them one of the most important vertical transportation systems in the world.

- Supports Continuous Passenger Flo : Unlike elevators, escalators operate in a constant loop and can handle thousands of passengers per hour. This makes them ideal for busy public spaces like airports, malls, and metro stations.

- Improves Accessibility and Convenienc : Escalators make it easier for people with luggage, strollers, or mobility challenges to move between floors without physical strain.

- Enhances Space Efficiency : By arranging escalators in parallel, crisscross, or spiral layouts, architects can optimize building space while maintaining smooth passenger circulation. Curved and spiral escalators also provide design flexibility in complex layouts.

- Provides High Safety Standards : Modern escalators include advanced safety features such as emergency stop buttons, comb plate sensors, handrail monitoring, and step demarcation lines. These systems reduce risks and comply with international standards like EN 115 and ASME A17.1.

- Offers Reliability and Durability : With robust truss structures, chain drives, and automatic lubrication systems, escalators are designed for long-term operation. In transit environments, they can run 18–20 hours a day with proper maintenance.

- Supports Outdoor and Harsh Environments : Outdoor escalators use weather-resistant materials, sealed electrical systems, and reinforced drainage to withstand rain, dust, and temperature fluctuations, ensuring reliable performance in open-air conditions.

- Reduces Congestion in High-Traffic Areas : Escalators provide predictable throughput during peak times, helping manage large crowds efficiently. They can be paired with moving walkways to further support smooth passenger distribution.

- Adds Architectural and Aesthetic Value : Glass balustrades, stainless steel finishes, and custom lighting options allow escalators to become both functional and visually appealing features in modern buildings.

What are the Main Limitations of Escalators

Although escalators provide many advantages in terms of capacity, accessibility, and safety, there are certain limitations you need to consider. The three most significant are high installation costs, strict building space requirements, and ongoing maintenance needs throughout the escalator’s lifecycle.

These challenges affect both project feasibility and long-term ownership costs. Environmental considerations such as high energy consumption and the difficulty of adapting escalators to major design changes also play a role in limiting their application in some projects.

- High Installation and Equipment Costs : The purchase and installation of escalators typically range from tens of thousands to over one million dollars, depending on size and configuration. Unlike elevators, escalators require extensive structural work, including pits, beams, and heavy-duty trusses, which increase upfront investment.

- Strict Space and Structural Requirements : Escalators demand long, unobstructed shafts with precise support points. Inclination angles, horizontal entry zones, and truss dimensions must all be coordinated with architectural layouts. In older or space-constrained buildings, installing escalators can be impractical without major reconstruction.

- Ongoing Maintenance Demands : Escalators are mechanical systems that run continuously, often 18–20 hours a day in transit hubs. They require regular inspections, lubrication, and part replacements. Annual maintenance contracts typically cost thousands of dollars per unit, making long-term ownership more expensive than many alternative systems.

- Limited Flexibility After Installation : Once installed, escalators cannot be easily moved, resized, or re-angled. Changing step width, speed, or structural alignment usually requires complete replacement. This inflexibility makes escalators less adaptable to future building redesigns or traffic flow changes.

- Energy Consumption and Environmental Concerns : Escalators consume significant amounts of electricity, particularly in high-traffic locations. Even with energy-saving features such as variable frequency drives and automatic start-stop functions, their continuous operation contributes to operating costs and environmental footprint. Outdoor escalators also face added challenges from weather exposure, which accelerates wear and increases maintenance needs.

Difference Between Escalators and Elevators

Escalators and elevators are different in where they are used, how they move, and how people use them.

Escalators are mainly for moving large numbers of people all the time. They work in a continuous loop, and people can step on anytime. This makes them common in places with heavy traffic like metro stations and airports.

Elevators are for moving people directly between floors in tall buildings. The cabin goes straight up and down with cables and counterweights. Passengers press a button to choose the floor, and the elevator takes them there. Elevators are essential for people with mobility needs and provide reliable point-to-point travel.

In short, escalators are best for continuous passenger flow, while elevators are best for vertical trips to chosen floors.

Passenger Capacity Comparison Escalators and Elevators

| Elevator (1.5 m/s) | Escalator (0.5 m/s) |

|---|---|

| 1000 kg load → ~300 people/hour | 600 mm width → ~4,500 people/hour |

| 1350 kg load → ~450 people/hour | 800 mm width → ~6,750 people/hour |

| 1600 kg load → ~600 people/hour | 1000 mm width → ~9,000 people/hour |

👉 The transport ratio of one elevator to one escalator is about 1:10.

How Do You Choose the Right Escalator?

Choosing an escalator isn’t just about price—it’s about safety, performance, and long-term value. The right choice depends on building type, passenger flow, and compliance with international standards. Start by evaluating the basics: What is the vertical rise between floors? How heavy is the expected traffic load? Will the escalator operate indoors or outdoors? These questions frame your technical requirements from the outset.

Next, review the specifications. Step width is critical—600 mm for light traffic, 800 mm for commercial buildings, and 1000 mm for heavy transport hubs. Speed and inclination must also match both regulations and rider comfort: for example, speeds are limited to 0.5 m/s when the angle exceeds 30°. Outdoor models should include weatherproofing, sealed electrical systems, and corrosion-resistant materials to withstand rain, dust, and temperature extremes.

Scalability and flexibility also matter. In shopping malls, parallel or crisscross layouts maximize space efficiency, while spiral or curved escalators add architectural impact. For airports or metro stations, long escalators with reinforced trusses and automatic lubrication systems ensure durability under 18–20 hours of daily operation.

Equally important are safety and compliance. Look for systems that meet EN 115 or ASME A17.1 standards and include features like emergency stop buttons, comb plate safety switches, and handrail speed monitoring. These protections reduce operational risks and safeguard passengers in high-traffic environments.

Finally, consider lifecycle costs. A cheaper escalator may carry higher maintenance expenses over time. Routine service, spare parts availability, and energy consumption should all factor into your decision. A dependable escalator manufacturers will provide transparent cost estimates, ongoing service packages, and proven reliability in similar projects.

That’s why working with global manufacturers like BDFUJI makes a difference. With expertise across residential, commercial, and public transport projects, BDFUJI engineers guide you from design selection to installation and long-term maintenance—delivering escalators built for safety, efficiency, and lasting performance.