Whether it is a shopping mall, airport or subway station, escalators are an important means of transporting people. But faced with complex classifications such as parallel escalators and spiral escalators, how do we choose an escalator that is truly suitable for the scene? Please read this article.

Types of escalators

Understanding the classification and application of different types of escalators is the first step in choosing the type of escalator. Escalators are divided into many types according to their structure, drive mode and application. Choosing the right escalator can effectively save energy, ensure passenger safety and optimize the visual effect of the space.

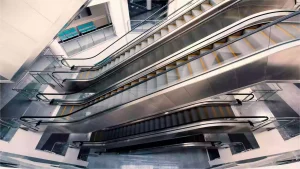

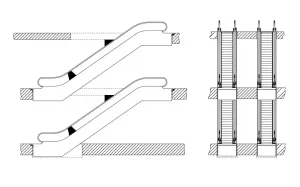

1. Parallel escalator

Parallel escalators can run side by side in the same or opposite directions. Due to their intuitive process, parallel escalators are common in shopping malls, airports and commercial buildings.

Best suited for: areas with large traffic and spacious space

Angle: usually 30° or 35°

Main advantages: convenient passenger movement and efficient direction control

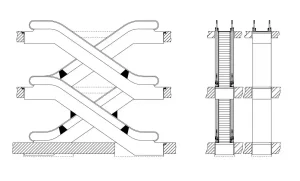

2. Cross escalator

This type of escalator runs alternately on each floor and is “X” shaped when viewed from the side. They are ideal when space is tight but multi-level access is required.

Best for: Department stores and subway stations

Main benefits: Space-saving, efficient handling of vertical traffic

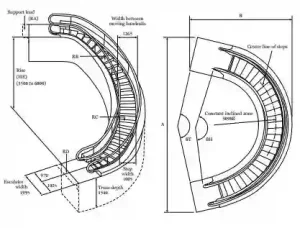

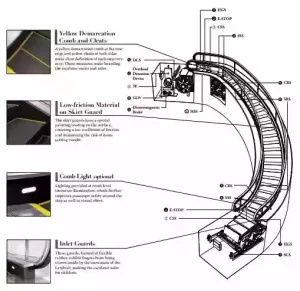

3. Spiral escalator

Spiral escalators are eye-catching and space-saving. Their curved design allows them to fit seamlessly into circular atriums or art buildings.

Best for: Museums, airports, high-end commercial buildings

Main challenges: Complex synchronization between motors and gear systems

4. Multiple parallel escalators

Multiple parallel escalators can handle dense two-way traffic, especially during peak hours.

Applications: Stadiums, exhibition halls, conference centers

Remarks: Requires large installation space and centralized control system

5. Curved escalator

Curved escalators are a hybrid of parallel and spiral escalators, designed for gentle curves in building layouts.

Application scenarios: Shopping malls or mixed-use venues with circular corridors

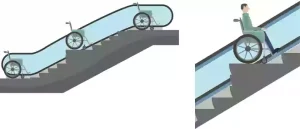

6. Step-type barrier-free escalators

Step-type barrier-free escalators are designed for barrier-free travel and can carry wheelchairs without lifts or ramps.

Standards: Must comply with ADA or EN81-70 requirements

Features: Larger platform area, safety gates, and sensor-based control systems

How different types of escalators work

Understanding the mechanics helps assess compatibility and maintenance needs.

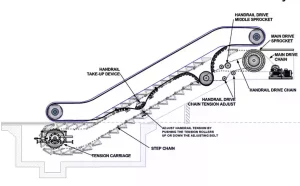

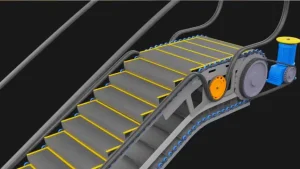

Step chain drive system

This is the standard mechanism for most escalators. A chain system is connected to the motor and pulls the steps along the rails. Each step is held in a horizontal position by a step roller mechanism.

Key components: Step chain, sprocket, main drive shaft, handrail motor

Spiral gears synchronized with the motor

Spiral or curved escalators require a finely tuned gear motor system to manage different radii and elevation angles.

Highlights: Real-time synchronization between curve angle and step movement

Installation difficulty: Higher installation precision and maintenance complexity

Smart escalators with predictive maintenance (AI monitoring)

Modern escalators are equipped with sensors and AI analytics to monitor vibration, temperature, and passenger flow.

Benefits: Early detection of faults, reduced downtime, and lower repair costs

🚀 BDFUJI’s smart escalators include predictive maintenance modules and support remote diagnostics, helping you reduce service interruptions and improve long-term safety.

What is the difference between indoor and outdoor escalators?

Indoor and outdoor escalators differ significantly in materials, protection levels, and design toughness.

Indoor escalators

Indoor escalators are designed for controlled environments such as shopping malls, office buildings, and airports.

Material: Powder-coated steel or aluminum

Standard inclination: 30° (more comfortable, takes up less space)

Protection level: Typically lower (IP20-IP33)

Maintenance requirements: lower exposure risk, simpler maintenance

Outdoor escalators

Outdoor escalators must withstand rain, dust, temperature fluctuations, and heavy passenger flow.

Material: 304/316 stainless steel, corrosion resistant

Protection level: IP54 or higher, waterproof and dustproof

Additional features: anti-slip pedal, sealed motor, weatherproof control panel

Surface coating: ≥12μm thick anti-rust treatment

Comparison of indoor and outdoor escalator requirements:

| Feature | Indoor Escalator | Outdoor Escalator |

|---|---|---|

| Material | Aluminum / Mild Steel | 304 / 316 Stainless Steel |

| Protection Level | IP33 or below | IP54 and above |

| Application Scenarios | Shopping Malls, Airports | Subway Entrances, Tourist Attractions |

| Coating Thickness | 6–8μm | ≥12μm Anti-Corrosion Paint |

| Additional Features | Basic Lighting, Silent Motor | Rain Cover, Anti-Slip Panel |

How to choose the right escalator for your building?

Matching the right escalator type according to traffic and space can save you 20% of energy consumption and operation and maintenance expenses. Here are the four factors for choosing an escalator solution:

Four-step selection method:

1.Calculate the passenger flow (PPH):

Low flow (<5000 people/hour): 600mm narrow ladder

High flow (>8000 people/hour): 1000mm wide ladder

2.Match the inclination angle and layout:

Floor height below 4 meters: 35° high inclination angle saves space

Floor height above 6 meters: 30° low inclination angle improves comfort

3.Compliance certification:

North America: ASME A17.1 (annual inspection and load test required)

Europe: EN 115 (mandatory installation of emergency stop button)

4.Energy efficiency selection:

BDFUJI Elevator’s EcoDrive series is equipped with VVVF drive (variable frequency speed regulation), which has passed ISO 25745 A+++ certification and saves 35% more electricity than ordinary motors.

Traffic efficiency of escalators of different widths:

| Pedal Width | Passenger Capacity (per hour) | Typical Application Scenarios |

|---|---|---|

| 600 mm | Up to 4,500 people | Community Malls, Small Commercial Spaces |

| 800 mm | Up to 7,500 people | Subway Stations, Public Transit Hubs |

| 1000 mm | Up to 12,000 people | Airports, Stadiums, Large Transport Terminals |

A hotel in Dubai uses BDFUJI 800mm parallel escalator, which, after matching with VVVF drive, reduces the daily electricity cost of 16 hours of operation by 22%.

Escalator maintenance and safety requirements

Safety is the top priority. Under normal circumstances, as long as you do a good job of daily maintenance of the escalator, the failure rate of the escalator is very low. If you ignore daily inspections, the maintenance cost of the escalator may skyrocket by 10 times. The following are the maintenance cycles and key points of escalators:

- Daily: Check the comb plate (to prevent foreign objects from getting stuck), lighting failure

- Weekly: Clean the pedal gap, lubricate the rail

- Monthly: Test the emergency stop button, check the motor temperature

- Yearly: Third-party certified load test (such as ASME standard)

Spiral escalator vs parallel escalator

The space utilization rate of spiral escalators is 40% higher than that of parallel escalators, but the cost and maintenance cost are also twice that of parallel escalators.

| Indicator | Parallel Escalator | Spiral Escalator |

|---|---|---|

| Floor Space Efficiency | Medium | Saves up to 30% of floor space |

| Cost (Approx.) | $100,000 | $300,000 |

| Maintenance Complexity | Low | High (requires special calibration tools) |

Spiral escalators offer space-saving advantages and aesthetic appeal but require a larger budget and more complex servicing. Parallel escalators, in contrast, are cost-effective and easier to maintain, making them ideal for standard commercial projects.

Typical application scenarios of various types of escalators

Choosing the right type of escalator according to the scenario can not only improve the user’s riding experience, but also extend the service life of the escalator.

Shopping malls: parallel escalators + anti-slip pedals (reduce the risk of high heels getting stuck)

Hospitals: barrier-free escalators + silent motors (less than 50 decibels)

Scenic spots: BDFUJI Elevator OutdoorPro series, with self-cleaning coating to cope with rainy and snowy weather

Other FAQs about escalators

Q: What is the service life of an escalator?

A: Usually 20-25 years, but regular replacement of key components (such as chains and gears) can extend it to 30 years.

Q: Can spiral escalators be used outdoors?

A: A customized waterproof version is required, and the cost increases by 45%. BDFUJI’s SpiralOutdoor series has been used in multiple seaside complexes.

Q: How to reduce escalator energy consumption?

A: Choose VVVF drive + automatic standby mode (such as reducing speed to 15% power when no one is there), BDFUJI’s Eco mode can save 40% of electricity costs.

From the type of escalator to the subsequent equipment maintenance, every decision is about safety, efficiency and cost.