A stainless steel elevator is a vertical lift powered by an electric motor, equipped with a stainless steel cabin, designed to transport people or goods in multi-story buildings.

It allows for easier movement of people or goods between floors in tall buildings, increasing the overall value of the structure.

Since its introduction, stainless steel elevators have gradually become the preferred vertical transportation solution for shopping malls, office buildings, hotels, and residential buildings due to their durability and corrosion resistance.

But what are its features? How is it constructed? And how does it work?

Let’s take a closer look.

What is a Stainless Steel Elevator?

A stainless steel elevator is a lift used for vertical transportation in multi-story buildings, driven by an electric motor.

Its key component—the cabin—is made of stainless steel materials.

Due to its strong corrosion resistance, abrasion resistance, and high aesthetic appeal, stainless steel elevators are especially suitable for high-rise buildings, shopping malls, hotels, and similar locations.

Compared to traditional elevators, stainless steel elevators not only improve operational efficiency but also enhance the overall visual appearance of the building.

How is The Stainless Steel Elevator Composed?

A stainless steel elevator typically consists of several systems and components, each with its own unique function and importance.

Understanding these components helps us better understand how the elevator operates:

1.Traction System

The traction system is responsible for the elevator’s movement, ensuring smooth up and down motion of the cabin.

It mainly consists of a traction machine, traction steel ropes/belts, guide wheels, and counterweight wheels.

The traction machine is driven by a motor, which moves the steel ropes/belts connected to the cabin and counterweight system, providing the lift power.

Additionally, stainless steel elevators may use hydraulic drive systems or gear and rack drive systems, which are typically chosen based on building requirements.

2.Guide System

The guide system ensures that the elevator cabin and counterweight move smoothly along the guide rails, preventing swaying.

It mainly consists of guide rails, guide shoes, and guide rail frames. The guide rails help the elevator maintain stable operation, while the guide shoes help the cabin move smoothly within the rails.

A good guide system ensures that the elevator maintains straight-line motion under all conditions, avoiding unnecessary deviation.

3.Cabin

The cabin is the part of the elevator used for transporting passengers or goods, consisting of a cabin frame and cabin body.

The cabin frame is responsible for support and bearing, while the cabin body carries passengers or goods.

When designing, it is important to ensure sufficient space and safety measures inside the cabin to enhance passenger comfort.

4.Door System

The door system is a safety feature of the elevator, used to seal the entrance between the cabin and the landing.

It includes cabin doors, landing doors, door operators, and door locking devices.

The door locking devices ensure that the doors do not open accidentally during operation, preventing accidents.

The design of the door system directly impacts the elevator’s safety and passenger convenience, ensuring strict control of the opening and closing during the elevator’s operation.

5.Weight Balancing System

The main function of this system is to balance the weight of the cabin, preventing excessive load during the elevator’s movement.

It mainly consists of the counterweight and weight compensation devices. The counterweight balances the cabin’s weight, reducing the motor’s load and improving the elevator’s efficiency.

By properly configuring the counterweight, the energy efficiency and stability of the stainless steel elevator will be greatly improved.

6.Electric Drive System

This is the power-driven system of the stainless steel elevator, responsible for providing power and controlling elevator speed.

It consists of the traction motor, power supply system, speed feedback devices, and motor speed control devices. The electric drive system adjusts the motor’s speed and power according to the elevator’s load and operating conditions.

It ensures smooth operation while adjusting speed and power consumption at different stages of operation, further enhancing efficiency.

7.Electrical Control System

The electrical control system is the “brain” of the elevator, responsible for controlling the elevator’s functions, including running, stopping, and leveling.

Main components include the control devices, position display devices, control panel (cabinet), leveling devices, and floor selectors.

These devices ensure the elevator operates efficiently and safely, automatically determining passenger needs and accurately stopping at each floor.

8.Safety Protection System

The safety protection system is the elevator’s safeguard, preventing accidents.

It includes speed limiters, safety clamps, rope grippers, buffers, and safety touch plates. These devices can quickly stop the stainless steel elevator in the event of a malfunction, preventing harm to passengers.

Types of Stainless Steel Elevators

There are three main types of stainless steel elevators: traction elevators, hydraulic elevators, and machine-room-less elevators.

Traction Elevators: Traction elevators use an electric motor to drive steel cables that lift and lower the cabin, providing smooth operation with minimal noise. They are typically used in high-rise buildings and offer efficient and stable performance.

Hydraulic Elevators: Hydraulic elevators use a hydraulic system for lifting and lowering, making them suitable for low-rise buildings or areas with specific needs. They are commonly used for carrying heavy loads or in environments with limited space, and are widely applied in low-rise buildings.

Machine-Room-Less Elevators: This type of elevator uses an advanced drive system design that eliminates the need for a traditional machine room, saving space. It is ideal for small buildings and modern designs. Machine-room-less elevators are not only easier to install but also enhance the flexibility of building designs.

Features of Stainless Steel Elevators

Now that you understand the basic components of a stainless steel elevator, let’s explore some of its notable features in more detail.

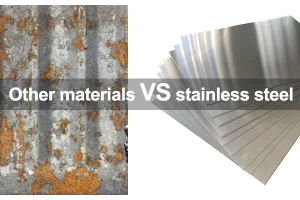

1. Strong Corrosion Resistance

Stainless steel material is highly resistant to corrosion caused by moisture, salt mist, and acidic or alkaline environments.

It is especially suitable for environments with high humidity or corrosive gases, such as hospitals, shopping malls, and restaurants.

Due to its strong corrosion resistance, stainless steel elevators can operate stably in these environments for a long time, reducing maintenance and replacement costs.

2. Aesthetic and Elegant

The smooth surface and modern appearance of stainless steel elevators allow them to seamlessly integrate with various architectural styles.

This design not only enhances the building’s appearance but also improves the visual effect of the overall space, making the elevator a part of the building.

3. High Durability

Stainless steel elevators are known for their strength and durability.

Even under conditions of frequent use over long periods, they can operate stably, reducing the frequency of repairs and part replacements.

This means that in high-traffic commercial environments, stainless steel elevators can maintain their performance for a longer period.

4. Efficient and Energy-Saving

Modern stainless steel elevators are equipped with intelligent control systems that automatically adjust the operating speed and energy consumption based on usage demands.

This helps to reduce the building’s energy consumption and save electricity.

5. Strong Safety

Stainless steel elevators are equipped with multiple safety protection systems, such as speed limiters, safety clamps, and buffers.

These systems ensure that the elevator can stop quickly in abnormal situations, protecting the safety of passengers.

How Elevators Work

The working principle of a stainless steel elevator is similar to that of traditional elevators. Both rely on the close cooperation of multiple systems to achieve smooth vertical movement.

Each system plays a key role in the elevator’s normal operation.

Below, we will provide a detailed explanation of the elevator’s working process and the technical details of each system:

1. Traction System

The traction system is the core component of the elevator’s operation.

It is driven by a motor that powers the traction machine. The traction wheel generates friction through steel cables, which move the cabin up and down along the guide rails.

2. Control System Dispatching

The control system uses a microprocessor to intelligently schedule the operation of the stainless steel elevator.

When passengers select a floor, the control system calculates the optimal path based on the floor requests and adjusts the elevator’s speed.

For example, in a multi-story shopping mall, the elevator may receive requests for multiple floors.

In this case, the control system dynamically adjusts the running path based on the elevator’s current position and target floors, avoiding unnecessary stops to improve transport efficiency and reduce passenger waiting time.

3. Safety System Protection

The elevator’s safety system includes safety devices such as speed limiters, safety clamps, and buffers.

These devices activate quickly when an abnormality occurs, stopping the elevator to prevent accidents.

For example, if the elevator exceeds the speed limit, the speed limiter immediately senses and activates to slow down the elevator or stop it directly.

If a serious malfunction occurs, the safety clamps quickly grip the guide rails, ensuring that the cabin stays in a safe position to prevent a dangerous fall.

Stainless Steel Elevator Cost

In the elevator market, the opacity and variability of elevator prices often leave buyers confused.

This is especially true for stainless steel elevators, where the high-quality materials and complex design requirements make the installation costs even harder to predict.

The diversity of cost components in stainless steel elevators offers significant opportunities for clients and suppliers who can master cost control techniques.

Therefore, gaining an understanding of the various components of stainless steel elevator prices in advance and planning accordingly will help you make more rational and cost-effective decisions.

Below are the average prices and factors influencing stainless steel elevators:

Average Price

The base price of stainless steel elevators typically ranges from $15,000 to $70,000, depending on the elevator’s capacity, speed, design, and customization requirements.

Customized Price

For high-end custom projects, the price of stainless steel elevators can even exceed $150,000, especially when there are special design and installation environment requirements, which usually increase costs.

Bulk Purchase Price

For large-scale building projects, bulk purchasing elevators can significantly reduce costs. Developers can typically receive 10% to 20% discounts through bulk purchasing, saving considerable expenses for the project.

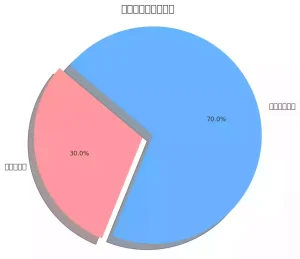

Overall, while the initial investment in stainless steel elevators is higher, their durability and low maintenance costs make them more cost-effective in terms of long-term investment returns. By 2026, stainless steel elevators are expected to account for over 30% of the global construction market, becoming one of the primary choices for building projects.

Elevator Installation Process

Installing a stainless steel elevator is a complex process that requires high precision. It typically includes the following key steps:

Step 1: Design and Planning

Before starting the installation, a detailed stainless steel elevator design plan must be developed based on the building’s structural requirements.

This plan should ensure that all parts of the elevator can seamlessly integrate with other building facilities, such as the shaft, machine room, and door frames.

Close cooperation with architects and engineering teams is necessary to ensure that the elevator design meets functional needs and perfectly blends with the building’s style and structure.

Step 2: Installation of Mechanical and Electrical Systems

Once the design is finalized, install the mechanical components, including the traction machine, cabin, and counterweight, within the shaft.

Next, install the electrical control system to ensure smooth operation, including intelligent control, speed adjustment, and safety functions.

The electrical system installation must comply with safety standards and coordinate with the building’s electrical system.

Step 3: Debugging and Acceptance

After installation, a thorough inspection ensures the elevator operates correctly. The steps include:

- Start the elevator and check for smooth operation and abnormal noise.

- Test the door system to ensure it opens and closes smoothly.

- Select various floors to confirm the elevator responds promptly and reaches the correct floor.

- Run the elevator at full speed to verify the speed limiter activates in case of overspeed.

- Simulate a failure in manual mode to check if the safety clamp functions properly.

- Inspect the buffer to ensure it slows the elevator effectively when approaching the pit.

These steps guarantee the elevator’s stability, safety, and provide essential data for future maintenance.

Step 4: Official Use

Once all commissioning work is completed and the acceptance standards are met, the elevator is officially put into service.