People use service elevators and freight elevators in similar ways, but they have important differences. These differences include their design, load capacity, and how they operate.

In this blog, we will help you see the main differences between service elevators and freight elevators. We will also explain their functions and where people use them.

The Main Difference Between Service Elevators and Freight Elevators

The design of service elevators is more inclined to personnel logistics support, while freight elevators emphasize industrial transportation efficiency and structural durability. The two have some overlap in their use. However, the choice should depend on load demand and frequency.

| Category | Service Elevator | Freight Elevator |

|---|---|---|

| Primary Function | Transport of staff and light goods | Transport of heavy goods and industrial equipment |

| Rated Load Capacity | 300–1000 kg | 1000–5000 kg (customizable up to 10,000 kg) |

| Internal Cabin Dimensions | 1.1 m × 1.4 m to 1.6 m × 2.2 m | 1.8 m × 2.5 m to 3.5 m × 4.5 m |

| Control System | Standard floor selector with service-priority feature | Enhanced positioning system with overload protection |

| Structural Reinforcement Level | Medium – suitable for stable daily operations | High – reinforced steel frame, impact-resistant, anti-corrosive |

| Typical Door Type | Automatic sliding door or center-opening door | Heavy-duty double doors, manual or automatic sliding doors |

What Is a Service Elevator?

People use service elevators, also called service lifts, for staff movement and transporting daily items in buildings. They help keep staff separate from goods and visitors. This improves the experience for passengers and makes transportation more efficient. You often see them in hotels, hospitals, and office buildings where operations need clear zones.

Features of Service Elevators?

Service elevators have a specific carrying capacity. They usually hold between 300kg and 1000kg. This capacity is good for moving lighter items. These items include cleaning supplies, bedding, and maintenance tools.

- Smaller car size: The service elevator car usually measures between 1.1m × 1.4m and 1.6m × 2.2m. This means it can be installed even if your elevator shaft is small.

- Smooth operation: The service elevator generally operates at a speed set between 0.5 and 1.0 m/s. This speed can reduce vibration when starting and stopping. It also ensures efficient up and down movement. This improves the stability of transporting employees and light items.

- Support flexible scheduling: Service elevators support the setting of the “service priority” function in the control system. For specific floors, the system will respond first. This reduces waiting time and improves work efficiency.

- Performance and aesthetics coexist: Service elevators usually use a design and load-bearing system similar to passenger elevators, taking into account performance while maintaining aesthetics.

At the same time, they consider the need for cargo transport. This balance ensures both practical use and attractive space design.

Category of Service Elevators

Logistics Service Elevators

Logistics service elevators are very suitable for transporting cleaning tools, guest room supplies, office supplies, etc. People usually place them in private areas. They help logistics staff move between floors in hotels, offices, and other buildings.

They are different from passenger elevators. This helps ensure a better experience for visitors.

Medical Service Elevators

Using medical service elevators, you can transport medicines, medical equipment, beds, wheelchairs and even cleaning carts. This type of elevator car generally uses antibacterial materials, contactless buttons and anti-cross-infection design, which meets the medical building hygiene standards.

Small Logistics Elevators

The rated load of small logistics elevators is usually 100kg to 500kg, with a relatively small footprint. It can carry a specific weight of goods. It is good for buildings with little shaft space and high efficiency needs.

We will configure different types of service elevators according to the use scenario. For example, medical service elevators often have antibacterial interiors and contactless control panels for hygiene. In contrast, logistics service elevators focus on fast multi-floor scheduling and safety features. These features include infrared sensing door controls and automatic stop systems.

Which Buildings Are Service Elevators Suitable For?

- Hotels and resorts: dedicated to employee transportation and room service

- Office buildings and commercial buildings: used by cleaning staff and maintenance teams

- Hospitals and rehabilitation institutions: transportation of medicines and cleaning equipment

- Backstage of retail malls: lightweight commodity handling and stocking channels

- High-end residential and apartment buildings: used by property staff and handling services

Service elevators work well in busy areas. They are good for moving light to medium items. They also help keep logistics separate from public paths.

When I choose a model, I will think about a few things. First, I will consider how often we will use it. Next, I will look at the load it needs to handle. Finally, I will consider how I arrange the space.

What is a Freight Elevator?

People use freight elevators, also called freight lifts or cargo elevators, for heavy transportation. They are ideal for moving large and heavy goods in industrial and commercial settings.

They usually have a high load capacity, often between 1000 kg and 5000 kg. They also feature wide car openings and strong floor structures. You can also use freight elevators in conjunction with industrial handling equipment such as forklifts and pallet trucks.

Features of Freight Elevators

- Strong load-bearing capacity: The standard model of freight elevators can carry between 1000kg and 5000kg. You can even expand it to carry 10,000 kg or more.

- Very large car size: The biggest size of the freight elevator car can be 3.5m × 4.5m. This size is used for moving whole pallets and large equipment.

- Durable and wear-resistant: The car of a freight elevator usually has anti-collision steel plates. The builders use strong, wear-resistant materials to construct the floor. This design is great for moving bulk goods.

- Low-speed and high-stability operation: The operating speed of freight elevators is between 0.25–0.5m/s, which is slower than that of service elevators, but can better ensure transportation safety and cargo stability.

- Support for fork lift and pallet truck entry and exit: Freight elevators have ramps at the door. This is different from service elevators. They use strong door leaves to help forklifts enter and exit easily.

Categories of Freight Elevators

Freight elevator manufacturers also follow this classification for product line segmentation.

Class A Freight Elevators: Suitable for Loading Ordinary Goods

Class A freight elevators can transport goods that do not exceed 25% of the rated load. This is good for scenes where people carry scattered items by hand or use small trolleys. You often see this in commercial warehousing, retail logistics, and property logistics.

Class B Freight Elevators: Loading Motor Vehicles

Engineers design Class B freight elevators for transporting vehicles. Their size and structure fit the needs of vehicles. These elevators meet the weight and entry requirements for vehicles. You can often find them in 4S stores, garage towers, and car showrooms.

C1 Cargo Elevator: Can Stop and Load Industrial Vehicles

The C1 cargo elevator can hold four-wheel industrial trucks, like electric transport trucks. These trucks can enter the elevator with their cargo and stop while the elevator operates. However, the total weight of the truck and cargo must not exceed the elevator’s rated load. This elevator is ideal for industrial production lines that need frequent loading and unloading.

C2 Cargo Elevator: Can Temporarily Load Industrial Vehicles

The C2 cargo elevator can hold a short-term load of up to 150% of its rated load. This means that the forklift or industrial truck must leave after loading the cargo. The vehicle cannot stay in the elevator. People often use C2 cargo elevators to move large equipment or heavy pallets.

C3 Cargo Elevator: Single High Load Loading

C3 cargo elevators can transport heavy cargo close to the maximum load. The car structure and drive system are stronger. This makes them good for large molds, industrial equipment, or heavy pallets. Please note that C3 cargo elevators do not allow vehicles and people to ride together.

Which Buildings Are Freight Elevators Suitable For?

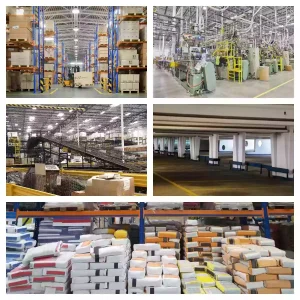

- Logistics distribution center: large-volume goods circulation between multiple floors

- Industrial manufacturing plant: production equipment and material transfer

- Warehousing center and cold chain warehouse: vertical storage and access of bulk goods

- Building materials market, furniture mall: frequent demand for large-scale goods handling

- Underground garage or heavy equipment area: need to connect to ground loading and unloading platform

Freight elevators have strong designs, tough cars, and wide platforms. They can carry heavy equipment, full pallets, and industrial materials.

These elevators are ideal for factories and logistics centers. They also work well in building materials markets and other sites. These places need elevators that can handle heavy loads and run smoothly.

Service Elevator Cost vs. Freight Elevator Cost Difference

Service elevators and freight elevators are quite different. They vary in load capacity, strength, installation, and operation. Because of these differences, their costs also vary greatly.

A service elevator can hold 1000kg. It usually costs 50% to 70% less than a freight elevator. However, service elevators are not good for handling heavy cargo. The following is the most direct difference between Service Elevator Cost and Freight Elevator Cost.

Service Elevator Cost

Average initial purchase cost: approximately RMB 120,000 to 300,000 (excluding civil engineering, installation, and taxes)

- Typical load configuration: 300kg to 1000kg, suitable for light material transportation

- Shaft requirements and floor space: small, suitable for building renovation or space-constrained projects

- Maintenance cost: low, suitable for high-frequency use places (such as hotels and hospitals)

- Key features: simple control system, medium decoration standard, focus on frequency and scheduling efficiency

People commonly use this type of elevator in office buildings, logistics, and medical transport. It is a typical example of a light commercial lift.

Freight / Cargo Elevator Cost

- Average initial purchase cost: about RMB 200,000 to RMB 800,000 or more, heavy-duty customized models are more expensive

- Typical load-bearing configuration: 1,000kg to 5,000kg (customizable to 10 tons)

- Structural configuration: thickened steel, industrial-grade rails, high-strength door system

- Installation and civil engineering requirements: higher standards for shaft size, pit depth, and ground load-bearing

- Maintenance cost: relatively high, structural components and load transmission systems need to be inspected regularly

- Application scenarios: suitable for industrial plants, storage centers, distribution hubs, etc., usually classified as industrial elevators or cargo lifts

Frequency elevators focus on being strong and able to carry heavy loads. They need better materials, support, and systems than service elevators. The cost difference comes from the equipment, installation, and maintenance.

Service elevator and freight elevator cost comparison table:

| Cost Factors | Service Elevator | Freight Elevator / Cargo Elevator |

|---|---|---|

| Procurement Cost | Medium | Medium to High (depending on load capacity and customization) |

| Load Capacity | Light-duty (300–1000 kg) | Heavy-duty (1000–10,000 kg) |

| Installation Complexity | Low to Medium | Medium to High |

| Maintenance & Parts Replacement Frequency | Low | Moderate to High |

| Building Integration Flexibility | High (suitable for narrow shafts) | Moderate (requires larger shaft space) |

Service vs. Freight Elevator: How to Choose?

Service elevators are mainly for people and light materials. They operate frequently and are easy to use.

Freight elevators are for heavy goods. They have a stronger structure and can hold more weight. According to different transport objects, handling methods and building purposes, we can consider the following aspects:

| Project Requirement | Recommended Elevator Type |

|---|---|

| Routine staff movement + light goods transportation | Service Elevator |

| Large goods, pallets, or heavy equipment handling | Freight Elevator |

| High-frequency use in medical, hotel, or service areas | Service Elevator (with service-priority feature) |

| Industrial plants and warehouse operations | Reinforced Freight Elevator |

| Complex logistics (requires forklift access) | Customized Freight Elevator |

When choosing service elevators and freight elevators, we need to think about several factors. The load requirements are important. This shows how often people use items. The type of items that people move matters too.

Finally, the installation conditions are also important factors. This will help us find the right vertical transportation solution.

FAQ

Q: Can we temporarily use passenger elevators as freight elevators?

A: Not recommended. The passenger elevator’s structure, floor materials, and door control system are not safe for heavy or odd-shaped objects. Temporary use of passenger elevators as freight elevators may cause equipment damage and safety hazards.

Q: Does the freight elevator require special maintenance?

A: Yes. We need to regularly check the motor system, limit devices, and car parts of the Freight Elevator. This is because the use environment is complex and the load is heavy. The maintenance frequency is higher than for regular elevators.

Q: How Much Weight Can The Service Elevator Carry?

A: The common standard load range is 300–1000kg. Developers can customize some commercial high-rise projects to 1200kg. However, we do not recommend using the Service Elevator for moving heavy equipment.

Q: Which Elevator is More Durable? What is The Maintenance Cost?

A:Freight elevators are stronger and made from better materials. However, they cost more to build and maintain than service elevators. Service elevators have a shorter maintenance cycle and are suitable for light-load and high-frequency scenarios.

Finally

Service elevators and freight elevators are clearly distinguished in terms of structural design, functional positioning and applicable building types. The former focuses on process separation and daily operation collaboration, while the latter emphasizes heavy-load stability and industrial-grade performance. During the project design phase, the team should choose the elevator type. This choice should be based on real load needs and operating conditions.

If you need more help with service elevators, freight elevators, or quotes from manufacturers, please contact BDFUJI. We can also assist with custom elevator designs and standard drawings.