We Build Escalators That Satisfy You

BDFUJI escalators use VVVF (variable frequency drive) system drive and ergonomic design, which makes operation smoother and energy consumption lower; high wear-resistant handrails and safety emergency stop devices ensure long-term zero-fault operation.

Through VVVF (variable frequency drive) control, BDFUJI escalators save 40% of electricity, effectively reducing operating costs; and the noise is less than 55 dB, making riding more comfortable.

We manufacture strictly in accordance with European standards, with multiple safety functions such as emergency stop devices and fault self-diagnosis; and there are a variety of escalator models to choose from, suitable for shopping malls, airports, subway stations, hotels, hospitals and office buildings and other major high-passenger flow scenes.

Choose BDFUJI escalators to get efficient, safe and reliable escalator solutions.

Welcome to consult!

Why Choose BDFUJI Escalator

BDFUJI escalators adopt international advanced technology, with stronger rigidity and anti-deformation ability. They have stylish appearance, smooth operation, low noise and durability, and are easy to install and maintain, which can bring higher value to your project.

Strict Delivery Management

We strictly review every detail to avoid delaying the installation and maintenance of escalators due to missing parts.

Large Project Verification

Many well-known airports, hospitals, and shopping malls are using BDFUJI escalators, and the actual operation data is reliable.

Flexible Customization

The appearance, load, size and speed can be adjusted according to needs to meet the needs of different buildings.

Transparent Cost Control

BDFUJI escalator factory direct sales, the price is closer to the actual cost.

Humanized Functions

Supports multiple extended functions to ensure that our escalators can operate stably in various environments.

Advanced Manufacturing Technology

High rigidity and anti-deformation technology are adopted to ensure the long-term stable operation of the escalator.

A Variety Of Escalator Structure Options To Suit Various Buildings

BDFUJI provides you with a variety of escalator layouts to adapt to different building spaces and transportation requirements.

Parallel And Serial Arrangement

The parallel and continuous arrangement of up and down escalators can achieve more efficient passage and save space, which is suitable for scenes with large flow of people.

Interrupt Arrangement

Escalators are arranged intermittently between floors, allowing customers to stop and browse from floor to floor, which is suitable for shopping malls and exhibition spaces.

Continuous Arrangement

Escalators are arranged continuously in the same direction on multiple floors to form an efficient movement path, which is suitable for places with large traffic such as airports and stadiums.

Criss-cross Arrangement

Escalators alternate directions floor by floor in a zigzag pattern, maximizing vertical space and naturally guiding visitors across all levels—ideal for department stores and museums.

BDFUJI Escalator Application Scenarios

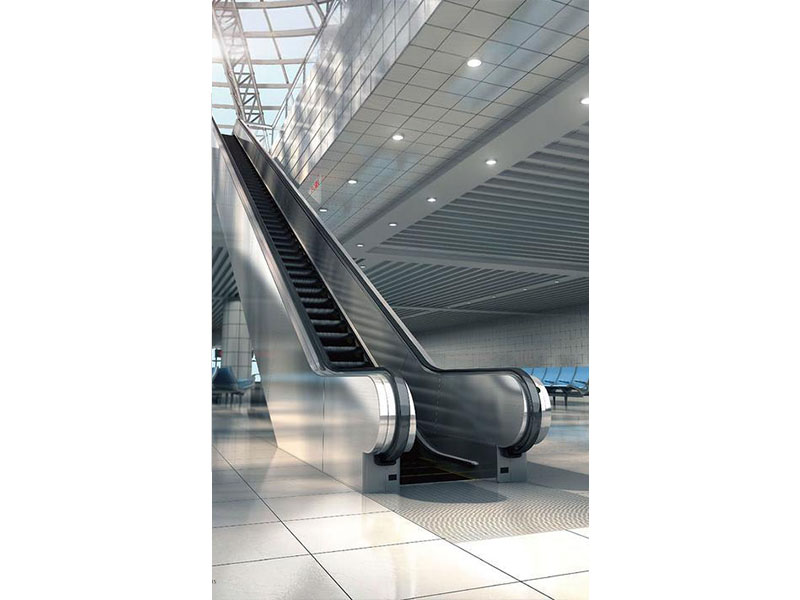

Airport Escalator

BDFUJI airport escalator steps are wider and can carry luggage. And it is suitable for large traffic and high frequency usage scenarios.

Shopping Mall Escalator

The BDFUJI shopping mall escalator is designed to carry a large flow of people and can accommodate multiple passengers at the same time.

Outdoor Escalators

BDFUJI outdoor escalators are made of high-strength materials to enhance the durability and wear resistance of the escalator, making it suitable for various outdoor environments.

Shopping Cart Escalator

BDFUJI shopping cart escalator is specially designed for transporting shopping carts, with wider steps and an additional support system to ensure that the shopping cart will not tilt or slide.

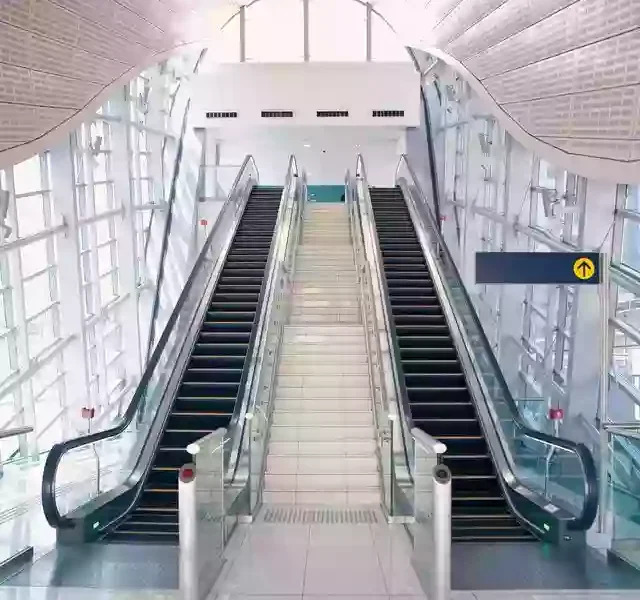

Parallel Escalators

Parallel escalators are the most common type, usually with two side-by-side units that enable two-way transportation, occupying less vertical space than traditional elevator systems, making them suitable for environments with limited space.

Multiple Parallel Escalators

Multiple parallel escalators can be flexibly set up for up and down travel, greatly improving the ability to guide the flow of people, and are particularly suitable for rapid passage during peak hours.

BDFUJI Escalator Standard And Optional Functions

| Standard Feature | Description |

|---|---|

| Skirt panel brush | The skirt brush, installed on both sides of the skirt panel above the step, prevents passengers’ shoes from touching the skirt panel and effectively avoids foreign objects from being drawn into the step gap. |

| Fault display | When a fault occurs, the trouble code is displayed on the screen, allowing quick and accurate identification of the fault location, greatly enhancing maintenance efficiency. |

| Handrail entrance | The streamlined handrail entrance design offers a modern and aesthetic appeal, giving the escalator a sense of elegance and user-friendliness, while reflecting careful attention to user experience. |

| Intermittent operation (automatic start/stop) | Sensors hidden within the entrance detect passengers stepping onto the escalator and automatically start operation. It stops automatically after all passengers leave to save energy. |

| Driver protection strand breaks | When the drive chain is overstretched or breaks, the escalator stops automatically to ensure safety. |

| Vertical type traction machine | Features smooth gear engagement and reduced friction, resulting in over 60% noise reduction and higher drive efficiency compared to traditional worm gear drives. |

| Optional Feature | Description |

|---|---|

| Skirt panel illumination | Streamlined lighting along the step track maintains visual elegance during operation while enhancing the escalator’s visibility within the building, offering a more comfortable and safe ride for passengers. |

| Handrail lighting | Customized LED light strips embedded in the conventional handrail guide with etched glass reduce the cost of aluminum handrails and enhance the overall appearance of the escalator. |

| Automatic oiling | VVVF-controlled automatic lubricating system provides ideal lubrication to the drive chain during operation, reducing maintenance workload and extending the service life of the transmission mechanism. |

| Running direction indication | Direction and prohibition indicators placed at the handrail entrances offer clear visual cues for passengers to ensure a safe and comfortable ride. |

| Heating device | Typically, three heating devices are installed per escalator: one near the host in the upper machine room, one in the middle section, and one in the lower machine room, providing comprehensive heating for the entire escalator system. |

| Comb | Bright yellow plastic combs enhance passenger safety and comfort during use. |

About Escalator

FAQ

How does escalator overload protection work?

Overload protection for escalators is usually achieved by installing load cells (or load detection devices) before and after the step group to monitor the load on the steps. When the total load exceeds the preset limit, the sensor triggers the safety switch, cuts off the control circuit, and quickly stops the drive motor and brake to prevent damage to the steps or injury to passengers due to overload.

What safety devices do escalators have?

The escalator is equipped with an emergency stop button and electromagnetic brake, which can stop the escalator quickly in case of emergency or power failure; the step misalignment, step missing, collapse and transmission chain loosening or break detection device will automatically shut down the escalator; overspeed, anti-reverse, handrail synchronization/breakage monitoring, as well as machine room hatch and comb plate safety switches form multiple linkage protection to ensure long-term and safe operation.

How do escalators stop safely in the event of a power outage or blackout?

When the escalator loses power, it relies on the electromagnetic brake (or mechanical slow stop system) to work with the frequency converter. The frequency converter first performs a controllable slow stop, and then the electromagnetic brake completely locks the steps and flywheel to ensure that passengers can get off the escalator safely without causing sudden stop shock.

What are the noise and vibration testing standards for escalators?

Noise: The operating noise of high-quality models is ≤57 dB(A) (the measurement point is located at the reducer), and the overall control is within ≤65 dB(A);

Vibration: In terms of passenger experience, ISO 18738-1 stipulates that the longitudinal and transverse peak-to-peak vibration amplitude PP value is ≤15 mg, and the average A95 value is ≤12 mg;

Exceeding standard handling: Check for reasons such as insufficient lubrication, poor gear meshing, bearing damage or guide rail offset, clean, lubricate, adjust or replace parts in a timely manner, and retest until compliance is restored.

What additional design is needed to use escalators outdoors?

Anti-corrosion treatment: The frame and shell are hot-dip galvanized or sprayed with zinc aluminum alloy coating, and 316/304 stainless steel key components and marine-grade paint are used.

apta.com

Waterproof seal: The drive motor, gearbox, bearings and electrical junction box all use IP66 or above seals and waterproof joints;

Drainage system: There are water collection tanks and drainage holes at the bottom of the steps and in the frame. The ground slope is ≥10° and covered with grilles to prevent water intrusion.

Xiamen Wellift Elevator Co., Ltd.

Enclosed switch: Outdoor safety switches and buttons are sealed, and the guide rails, sensors, etc. use dust covers to ensure stable operation in rain, snow and dusty environments.

What types of alarms does the escalator fault alarm system include?

Common alarms: overload alarm, step missing alarm, step collapse alarm, chain break alarm, overspeed/reverse alarm, handrail out of sync alarm, cabin cover open alarm, etc. Response process: The alarm immediately cuts off the drive and stops, and the control cabinet indicates the type of fault; before the maintenance personnel carry the key to reset, they must find out and eliminate the hidden dangers, and then confirm the reset through the control key or panel.

How do you ensure the quality of escalators?

Complete certifications: IOS9001/14001, CE, OHSAS18001 and other certifications. Strict inspection: more than ten quality inspections throughout the process, zero missing parts, zero complaints.

Can you use your own brand?

Support OEM/ODM customization, you can affix your own brand logo, the appearance and configuration can be adjusted according to needs, and guarantee the subsequent maintenance benefits.

How to install and maintain the elevator after purchasing it?

BDFUJI has professional installation and after-sales partners in more than 150 countries around the world, who can provide you with a full range of installation and maintenance services.

How long is the warranty period for BDFUJI escalators?

We provide a standard 2-year warranty service, during which faulty parts will be replaced free of charge if there is no human damage. Important accessories are warrantied for 5 years.

What certifications does BDFUJI have?

It has international and regional certifications: IOS9001/14001, CE, OHSAS18001, etc., which meet local regulations and industry standards.

How long is the delivery cycle usually?

The standard production cycle is 6-8 weeks. If expedited, it can be negotiated. The specific time depends on the configuration and production capacity.