Cargo/Freight Elevator

BDFUJI Freight/Cargo Elevators are made for places where goods need to be moved a lot. BDFUJI’s cargo elevator solutions have been proven to keep your goods moving safely, reliably, and efficiently for a long time.

Cargo/Freight Elevators Designed For Industry And Commerce

BDFUJI is a professional cargo/freight elevator manufacturer. We know what cargo elevators mean to you, so whether you are transporting a few tons or more than ten tons of cargo, our cargo elevators are always durable and stable. For different industrial and commercial scene requirements, we can also provide flexible cargo elevator customization solutions to enable forklifts, pallets and containers to operate efficiently on all floors.

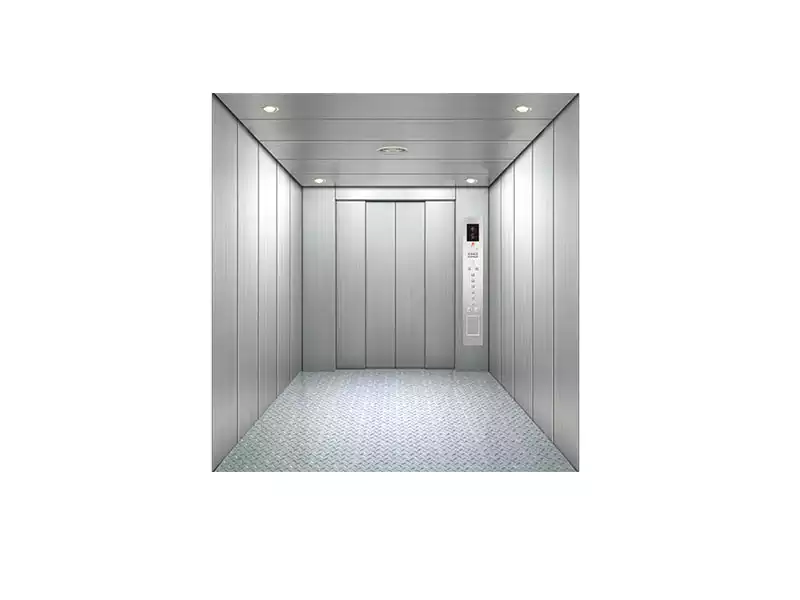

BDFUJI cargo elevators are equipped with multiple safety mechanisms, including overload protection, limit switches, safety doors and other safety protection measures. The car is made of wear-resistant and non-slip material, making it more durable in frequent and harsh cargo handling environments. At the same time, we provide you with customized services. You can adjust the size of the freight elevator or add cargo fixings as needed.

Our cargo elevators have obtained multiple certifications such as CE\IOS, quality assurance, and a maximum load capacity of 5,000 kg. Factory direct sales, more cost-effective. It is an ideal choice for warehouses, factories, supermarkets, logistics centers and industrial buildings.

Welcome to consult!

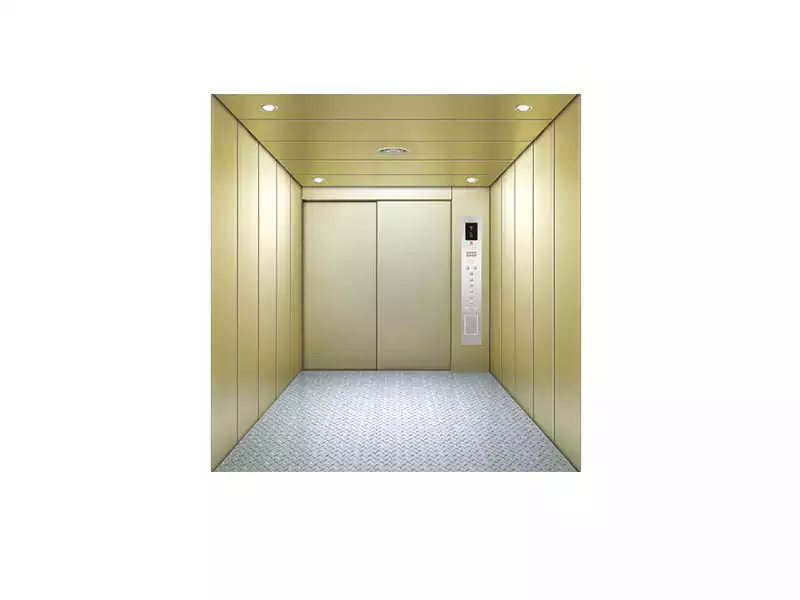

BDFUJI Freight/Cargo Elevator Type

Why Choose BDFUJI As Your Preferred Cargo Elevator Manufacturer?

To do a great job, you need hard work every day. BDFUJI is the same. We keep improving the core technology and making of our Freight/Cargo Elevators to meet your cargo needs.

Born for heavy goods

We know that the transportation task of cargo elevators is never easy. Therefore, BDFUJI elevators adopt all-steel structures and multiple door opening methods to create a more stable transportation environment for heavy goods and ensure the dual safety of personnel and materials.

Leading technology

We always pay attention to the forefront of technology and continuously optimize the performance of control systems and components, just to make your elevators consistently reliable and durable, reduce downtime, and improve overall efficiency.

Strong and efficient

Different scenarios have different needs. Our elevators can not only cope with the heavy-load challenges of large industrial projects, but also maintain efficient operation in limited spaces. No matter how harsh the use environment is, we can provide a suitable Cargo elevator solution

BDFUJI Cargo/Freight Elevator Application Scenarios

Grow your possibilities with cargo elevators that meet your needs and go beyond your industry’s demands.

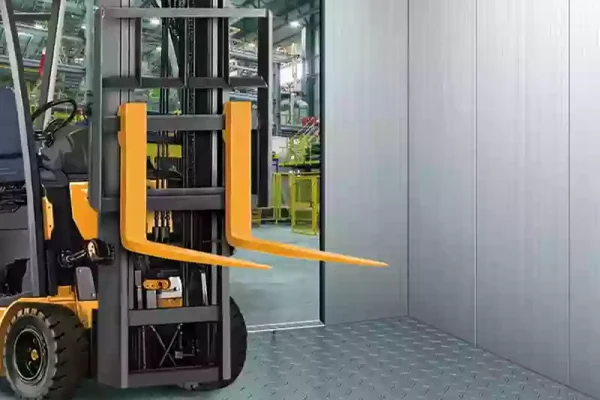

Factory Cargo Elevator

BDFUJI cargo elevators have high load-bearing capacity and large door design, which can easily handle the frequent handling of bulk materials such as pallets and cargo boxes, improve the efficiency of vertical circulation in warehouses, and reduce labor costs.

Shopping Mall Cargo Elevator

BDFUJI commercial cargo elevator supports multi-point stopping, through-door opening, and wide car design, making it very suitable for transporting bulk items between storage and sales floors.

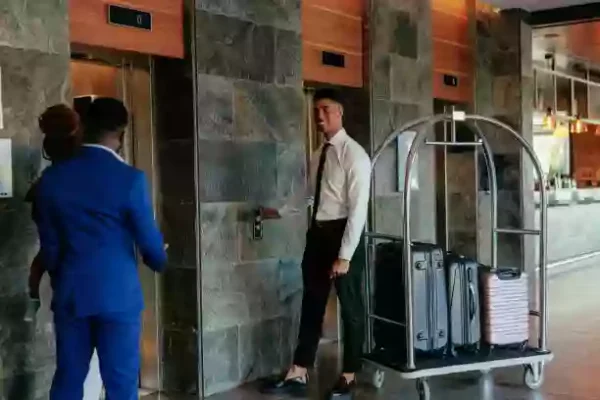

Hotel Cargo Elevator

BDFUJI hotel cargo elevator is equipped with low-noise motor and smooth door opening and closing system to ensure that the transportation of goods does not affect the lobby area. It is suitable for the transportation of logistics materials such as linens, electrical appliances, and meals.

Passenger And Cargo Elevators For Office Buildings

BDFUJI provides multi-door and multi-size solutions, supports front-to-back through-design, and realizes efficient transfer from storage to sales floor, which is suitable for medium and large supermarkets and multi-storey retail spaces.

Cold Chain Warehouse Cargo Elevators

BDFUJI cargo elevators can be equipped with anti-corrosion coatings, closed door systems and anti-low temperature control systems to meet food-grade safety requirements, making them suitable for cold chain distribution and food production environments.

Hospital Cargo Elevator

BDFUJI hospital cargo elevators are designed to meet medical and health standards, support customized stainless steel antibacterial interiors, and can stably transport medicines, garbage trucks, cleaning trucks and other medical logistics equipment.

About Cargo Elevators

FAQ

What is a cargo elevator?

A cargo elevator is a heavy-duty lift designed to transport goods, materials, and equipment vertically within commercial or industrial buildings. Unlike passenger elevators, cargo elevators prioritize load capacity, durability, and functionality, often featuring reinforced cabins, larger doors, and simple interiors suited for heavy use.

How much does a cargo elevator cost?

The cost of a cargo elevator varies depending on capacity, size, travel height, and customization needs. Standard BDFUJI cargo elevators typically range from USD 10,000 to USD 50,000, excluding installation. For a precise quote, please contact us with your project specifications.

What types of cargo elevators are there?

Common types include:

- Traction cargo elevators – For high-rise or heavy-duty applications

- Hydraulic cargo elevators – Suitable for low-rise buildings

- cargo dumbwaiters – For small goods and limited space

BDFUJI supports custom designs for each type to fit your project needs.

What are the size and capacity requirements?

Cargo elevators typically range from 1000kg to 5000kg in load capacity, with cabin sizes adapted to pallets, trolleys, or large goods. Standard widths range from 1500mm to 2500mm, with customizable door configurations. BDFUJI engineers can tailor shaft size, travel height, and platform dimensions based on your application.

What safety features are required for cargo elevators?

Cargo elevators must include essential safety features such as:

- Overload protection

- Emergency stop and alarm

- Door interlocks

- Limit switches

- Manual lowering in power loss

- Slip-resistant flooring

BDFUJI cargo elevators comply with CE and EAC safety standards and undergo full-load testing before delivery.

What type of doors are available for cargo elevators?

BDFUJI offers a variety of door types to suit different building layouts and loading requirements:

- Center Opening Doors: Ideal for wider openings and faster loading; commonly used in logistics and retail buildings.

- Single Slide Doors: Space-saving option suitable for narrow shafts or side loading conditions.

- Vertical Bi-Parting Doors: Open upward and downward simultaneously; perfect for factories and environments with limited horizontal clearance.

- Manual or Swing Doors: Available for small cargo lifts or low-frequency service areas.

All door types can be customized in terms of material (stainless steel, powder-coated steel, etc.) and size, and are equipped with safety interlocks as standard. We also support front-only or through-type (front and rear) openings to match your building design.

How to ensure the quality of cargo elevators?

Complete certifications: IOS9001/14001, CE, OHSAS18001 and other certifications. Strict inspection: more than ten quality inspections throughout the process, zero missing parts, zero complaints.

Can you use your own brand?

Support OEM/ODM customization, you can affix your own brand logo, the appearance and configuration can be adjusted according to needs, and guarantee the subsequent maintenance benefits.

How to install and maintain the elevator after purchasing it?

BDFUJI has professional installation and after-sales partners in more than 150 countries around the world, who can provide you with a full range of installation and maintenance services.

What is the warranty period for BDFUJI freight elevators?

We provide a standard 2-year warranty service, during which faulty parts will be replaced free of charge if there is no human damage. Important accessories are warrantied for 5 years.

What certifications does BDFUJI have?

It has international and regional certifications: IOS9001/14001, CE, OHSAS18001, etc., which meet local regulations and industry standards.

How long is the delivery cycle usually?

The standard production cycle is 6-8 weeks. If expedited, it can be negotiated. The specific time depends on the configuration and production capacity.