Nowadays, elevators have become an indispensable means of vertical transportation. According to statistics, an elevator with unqualified quality may cause safety accidents with losses of up to millions of yuan in its 20-year service life.

As an expert with 15 years of experience in elevator engineering, I have witnessed too many tragedies caused by purchasing errors: from frequent failures caused by insufficient load, to accidents caused by the lack of safety systems, to high electricity bills caused by outdated technology. To avoid these problems, please be sure to read this article.

Five Key Factors That Must Be Considered Before Purchasing

1. Accurate analysis of building characteristics

Building type:

- Residential: Focus on riding comfort (noise <45 decibels)

- Office building: Morning peak transportation capacity (5-minute load rate ≥12%)

- Hospital: Special size of stretcher elevator (1100kg/1.6m×1.5m)

Crowd flow calculation:

- Basic formula: Number of elevators = total number of people × 20%/(single elevator capacity × 5-minute transport times)

- Peak period verification: waiting time should not exceed 30 seconds

2. Scientific Matching of Technical Parameters

Load selection standards

| Building Type | Recommended Capacity | Person Capacity | Door Width | Minimum Shaft Dimensions (W×D) |

|---|---|---|---|---|

| Standard Residential | 800kg (1760 lbs) | 6-8 persons | 800mm | 1600×1500mm |

| Luxury Apartments | 1000kg (2200 lbs) | 10-13 persons | 900mm | 1800×1600mm |

| Office Buildings | 1350kg (2970 lbs) | 15-18 persons | 1100mm | 2000×1800mm |

| Commercial Complexes | 1600kg (3520 lbs) | 20-25 persons | 1200mm | 2200×2000mm |

| Hospitals (Stretcher) | 1600kg (3520 lbs) | 8+1 stretcher | 1100mm | 2100×2200mm |

| Mosques/Special Use | 1000-1350kg | Custom | 900-1100mm | Custom Design |

Speed configuration guide

- Low-rise building (≤10 floors): 1.0-1.5m/s

- Mid-rise building (11-20 floors): 1.75-2.0m/s

- High-rise building (21-30 floors): 2.5-3.5m/s

- Super high-rise (>30 floors): 4.0-6.0m/s

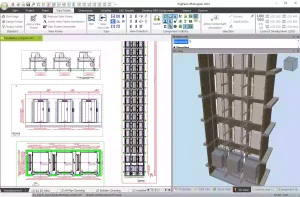

3. Three-dimensional Considerations for Space Planning

Shaft size:

- Minimum size of machine room-less elevator: 1600mm×1500mm

- Additional space for small machine room elevator: ≥2000mm×2000mm

Pit depth:

- Hydraulic: ≥1200mm

- Traction: ≥1400mm

Top floor height:

- Ordinary model: ≥3800mm

- High-speed model: ≥4500mm

4. Energy Efficiency Level and Economy

Interpretation of energy efficiency label:

- Level 1 energy efficiency: more than 35% energy saving than ordinary models

- Level 2 energy efficiency: 20-35% energy saving

- Level 3 energy efficiency: benchmark level

Energy-saving technology:

- Permanent magnet synchronous host (40% energy saving than traditional asynchronous machine)

- Energy feedback device (can recover 15-20% energy consumption)

- Intelligent group control system (save 10-15% total energy consumption)

5. In-depth Compliance Verification

Regional specification differences:

| Region | Mandatory Standard | Special Requirements | Certification Body |

|---|---|---|---|

| Gulf Countries | GSO EN 81-20 | Arabic language operating interface | GSO |

| MERCOSUR (South America) | IRAM EN 81-1 | Seismic design (Chile/Peru) | OCA |

| North Africa | DTI 356/2017 | Silent mode for mosques | ONTNS |

Special requirements:

- Hospital elevators: bed operation box must be configured

- Public buildings: Braille buttons must be set

- High-rise residential buildings: fire resistance limit of fire doors ≥ 1 hour

BDFUJ elevator compliance consulting services can help customers pass 98% of acceptance inspections at one time, avoiding the loss of repeated rectification.

List of Necessary Safety Configurations for Passenger Elevators

Emergency System:

- Backup power supply

- Fire emergency landing function

- Earthquake sensing device

Protection System:

- Infrared light curtain door protection

- Automatic shutdown due to overload

- Dual brake system

Passenger Elevator Maintenance Guide

Standardized maintenance can extend the life of the elevator by 3-5 years

Maintenance cycle comparison table

| Period | Maintenance Task | Importance |

|---|---|---|

| Daily | Button/Display Inspection | ★★★★ |

| Monthly | Guide Rail Lubrication/Safety Test | ★★★★☆ |

| Quarterly | Whole System Diagnostics | ★★★★★ |

| Annually | Third-Party Safety Certification | ★★★★★ |

Choose a similar BDFUJ intelligent monitoring system, which can realize fault warning through the Internet of Things and reduce 40% of sudden downtime.

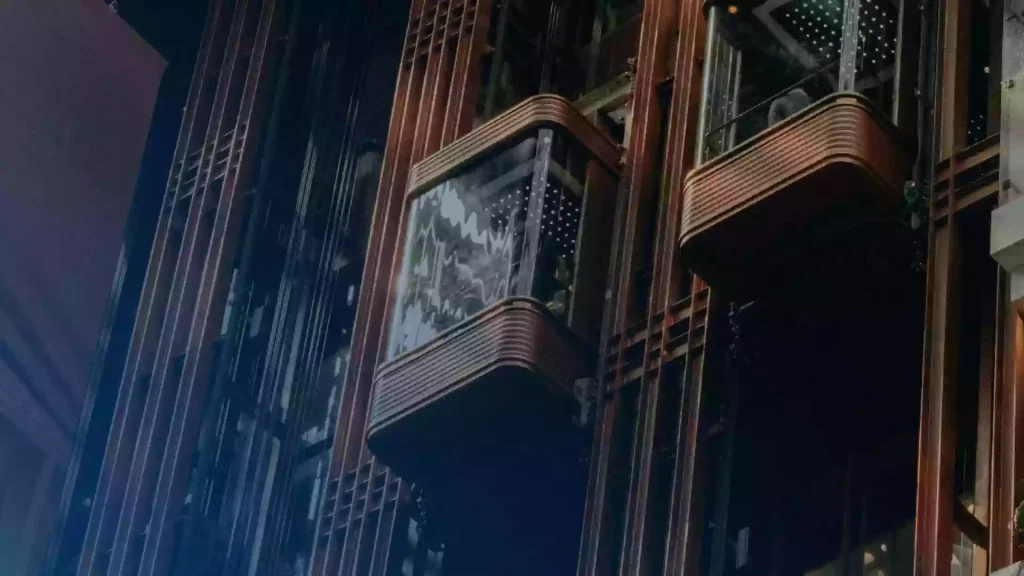

Three Major Elevator Types Selection Strategy

Technical parameter comparison

Type applicable scene speed Energy consumption level in the range of degrees

Hydraulic type 2-5-story building 0.5-1m/s high

No machine room 5-20 floors 1-2.5m/s medium

Traction type 20 floors and above 2-5m/s low

Passenger Elevator Cost Structure and Budget Control

Expense Breakdown Details

Equipment cost (accounting for 40-60% of the total investment):

- Hydraulic type: 150,000-350,000 dollar

- No machine room: 200,000-500,000 dollar

- Traction type: 350,000-900,000 dollar

Installation cost (20-30%)

Annual maintenance fee (3-5% of the equipment price)

How to select high-quality suppliers

After an in-depth analysis of the entire process of elevator purchase, we have extracted three golden decision-making principles:

1. Safety First Principle

- Certification standards are the bottom line: look for mandatory certifications such as CE\IOS

- Safety configuration cannot be omitted: ARD devices, dual brakes, etc. must be equipped

- Regular inspections must be implemented: establish a complete maintenance file

2. Full-cycle Cost Principle

Cost type ratio optimization strategy

- Purchase cost 40% to choose cost-effective models

- Energy cost 30% to use VVVF frequency conversion technology

- Maintenance cost 20% to sign a long-term maintenance agreement

- Transformation cost 10% to reserve upgrade space

3. Service Network Principle

Quality suppliers must meet the following requirements:

- Provide a 2-hour emergency response commitment

- Own a spare parts warehouse

- Provide remote diagnostic support

Passenger Elevator Procurement Process

Demand diagnosis stage (1-2 weeks)

- Organize multi-party talks between buildings and properties

- Commission a professional company to calculate traffic

- Determine the initial budget range

Scheme comparison stage (2-3 weeks)

- Collect at least 3 brand solutions

- Inspect installed projects on the spot

- Compare full-cycle cost analysis

Contract signing stage (1 week)

- Clear acceptance standards

- Agreed maintenance terms

- Determine liability for breach of contract

Installation supervision stage (depending on the scale of the project)

- Send on-site supervision

- Acceptance in stages

- Retain construction files

We have specially prepared the “Self-check List for Elevator Purchase”, which contains 27 key inspection items. Please contact the BDFUJ customer service team for free. Remember, a professional purchase decision will escort your building’s vertical transportation for the next 20 years.

[Resource download button] Get the “Self-check List for Elevator Purchase” now

[Click to consult now] Make an appointment for 1-on-1 consultation with an expert

This article is based on the real experience of numerous experts in the elevator industry. It is recommended that you save or bookmark it as a reference manual for purchasing passenger elevators.