Elevators are widely used in office buildings, apartments, and public spaces because they are convenient and efficient. There are different types of elevators, including traction elevators, mrl elevators, hydraulic elevators, and screw elevators.

Among all these types, mrl elevators and traction elevators are the most common and popular. So, what makes them different from each other?

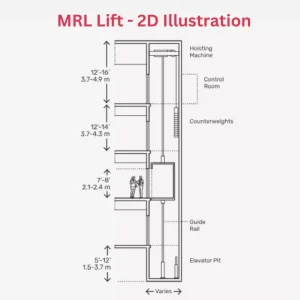

Overview and Operating Principle of Mrl Elevators

Mrl elevators are a modern type of elevator that does not need a separate machine room. The main parts, like the motor and control system, are built into the elevator shaft, saving space in the building.

Mrl Elevator Structure

-

Motor: Uses a small, gearless motor that is efficient and saves energy.

-

Drive system: This system moves the elevator smoothly and is built into the shaft.

-

Control system: This controls the elevator’s movement, speed, and stops.

-

Safety system: Includes brakes and speed limiters for safety.

-

Tracks: These keep the elevator car moving straight up and down.

-

Cables: These are used to lift and lower the elevator car.

Mrl Elevators How It Works

Mrl elevators use a motor that moves a pulley system, just like traditional elevators. But unlike traditional ones, Mrl elevators use a smaller motor with no gears, making them quieter and more energy-efficient.

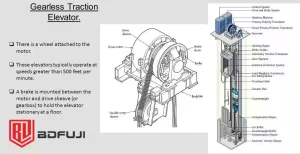

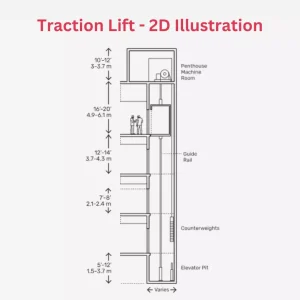

Overview and Operating Principle of Traction Elevators

Traction elevators are one of the oldest and most commonly used types of elevators. They need a machine room where the motor and other important parts are stored. Traction elevators are very powerful and are often used in tall buildings.

Traction Elevator Structure

-

Motor: Uses a large motor that powers the elevator.

-

Pulley system: A motor drives a pulley, which moves the elevator using cables.

-

Steel cables: These cables are used to lift the elevator car.

-

Counterweight system: This helps balance the weight of the elevator car and reduce energy use.

-

Brakes: These stop the elevator safely in emergencies.

-

Tracks: These keep the elevator car stable and moving in a straight line.

Traction Elevator How It Works

Traction elevators work by using a motor to drive a pulley that pulls the elevator car up and down. The counterweight balances the car, making the motor’s job easier and saving energy.

Recommended reading:

How does a Traction Elevator Work?

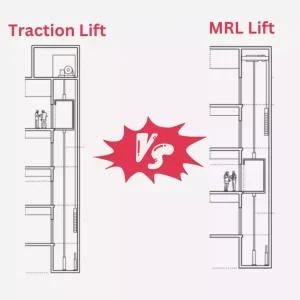

What is the Difference Between Mrl Elevator and Traction Elevator?

When choosing between Mrl elevators and Traction elevators, there are a few main differences. Let’s look at these differences step by step:

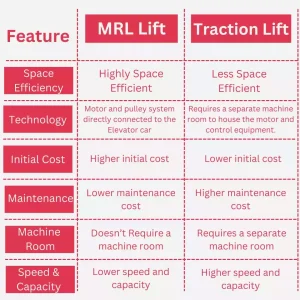

Space Efficiency

-

Mrl Elevators: Mrl elevators save space because they do not need a separate machine room. The motor and other parts are built directly into the elevator shaft, making them great for buildings where space is limited.

-

Traction Elevators: Traction elevators need a machine room, which takes up more space in the building. This room holds the motor and other important parts. While this requires more space, it helps the elevator work well in tall buildings.

Installation Costs

-

Mrl Elevators: Mrl elevators are usually cheaper to install because there is no need for a separate machine room. This can help save money during the building process. Installation costs typically range from $90,000 to $400,000 depending on the building size.

-

Traction Elevators: Traction elevators usually cost more to install because they need a machine room. This extra space and equipment make installation more expensive. Costs for Traction elevators generally range from $150,000 to $500,000 depending on the system and building needs.

Energy Efficiency

-

Mrl Elevators: Mrl elevators are often more energy-efficient. They use technology like regenerative drives to capture and reuse energy, which can lower your electricity bills.

-

Traction Elevators: Traction elevators are also energy-efficient, especially newer models with advanced motors. While they might not always have regenerative drives, they are still good at saving energy in larger buildings.

Performance

-

Mrl Elevators: Mrl elevators are best for low to mid-rise buildings (up to 20 stories). They provide smooth, efficient rides and are great for buildings with moderate traffic. But, they are not ideal for very tall buildings.

-

Traction Elevators: Traction elevators are better for high-rise buildings (over 20 stories). They can move faster, carry heavier loads, and handle more passengers, making them a good choice for tall buildings with many people using the elevator.

Long-Term Operation Costs

-

Mrl Elevators: Mrl elevators usually have lower operating costs because they are more energy-efficient. But, maintenance can sometimes cost more if the system uses special parts. Annual operating costs are usually around $5,000 to $20,000, depending on how much the elevator is used.

-

Traction Elevators: Traction elevators might have higher maintenance costs because they need more parts and a machine room. But, they are often more flexible with parts and service, which can help lower costs over time. Annual operating costs are typically between $10,000 and $30,000.

Mrl Elevator vs Traction Elevator: Comparison Chart

To help you better compare MRL elevators and Traction elevators, we put their main features into easy-to-read tables.

Table 1: Overview – Traction Conventional vs. Traction MRL Elevator

| Feature | Traction Conventional | Traction MRL (Machine Room-Less) |

|---|---|---|

| Machine Room | Needed (usually above the shaft) | Not needed (equipment inside the shaft) |

| Space Use | Takes up a lot of space in the building | Saves space; very efficient use of building space |

| Building Height | Good for tall and super-tall buildings (246 ft to 1640 ft) | Good for mid to high-rise buildings (up to 250 ft, some up to 492 ft) |

| Max Speed | Gear type: up to 6.5 ft/sec; Gearless: up to 66 ft/sec | Up to 8 ft/sec (500 ft/min); often limited above 11.5 ft/sec |

| Max Load | Can carry over 10,000 lbs | Usually up to 5,000 lbs (some limit ~2,500 lbs) |

| Max Travel Distance | Gear: up to 246 ft; Gearless: up to 1640 ft | Up to 250 ft; some models up to 492 ft |

| Energy Efficiency | Very good (especially gearless with energy-saving systems) | Also very good; often includes gearless motor and energy-saving drives |

| Installation Cost | Higher | Lower |

| Maintenance Access | Easy to service; room allows good access | Harder to service; equipment inside the shaft |

| Proprietary Risk | Low; many open systems available | Higher; many systems are brand-specific |

| Lifespan | Proven; slightly longer expected life | Varies; electronics may wear out faster |

| Noise/Vibration | Quiet; machine room helps reduce noise | Quiet, but may have some shaft noise |

Table 2: Cost Impact Comparison

| Cost Type | Traction Conventional (Open System) | Traction MRL (Proprietary System) |

|---|---|---|

| Initial Cost | Higher (e.g., $150,000–$500,000+ per unit) | Lower (e.g., $90,000–$400,000+ per unit) |

| Energy Cost | Low power use; gearless type is very efficient | Often lower due to energy-saving motor and systems |

| Maintenance Cost | Competitive contracts can help reduce costs over time | May cost more long-term due to limited service options |

| Major Upgrades | More flexible and lower cost with open system options | Can be costly due to brand-specific parts |

| Service Contracts | Many vendors to choose from; better pricing | Often limited to one vendor; may cost more |

| Total Cost Over 15/30 Years | Usually lower and more predictable | May be much higher due to hidden costs |

Mrl Elevator Pros and Cons

When choosing an elevator for a building with limited space, Mrl elevators have several advantages, but they also come with a few disadvantages.

| Pros | Cons |

|---|---|

| Saves space: No need for a machine room, which saves space in the building. | Not for tall buildings: Best for buildings with up to 20 floors. |

| Lower installation cost: Costs less to install because there’s no machine room. | Higher maintenance: Some parts might be expensive to replace. |

| Energy-saving: Uses less power and helps lower electricity bills. | Less powerful: Not as fast or able to carry as much weight as Traction elevators. |

| Quieter: Mrl elevators are quieter than regular elevators. | Special repairs: Repairs can be more difficult and need special knowledge. |

Traction Elevator Pros and Cons

Traction elevators are great for taller buildings and areas with more traffic, but they have some downsides in terms of space and cost.

| Pros | Cons |

|---|---|

| Handles more weight: Can carry more passengers and weight, making it great for tall buildings. | Needs more space: Requires a machine room, which takes up extra space. |

| Faster: Moves quickly, which is good for high-rise buildings. | Costs more to install: The extra space and equipment make it more expensive. |

| Lasts longer: With proper care, these elevators last for many years. | More expensive maintenance: Can be more costly to maintain over time. |

| Easy to repair: Parts are easy to find, and repairs are simple. | Noisy: Can make more noise because of the machine room and motor. |

Mrl Elevator vs Traction Elevator: How to Choose

Choosing between a Traction Conventional and a Traction Mrl elevator depends on several factors:

Building Height and Traffic:

-

For buildings with more than 20 floors or heavy passenger traffic, a conventional Traction elevator is usually the better choice due to its higher capacity and speed.

-

For low to mid-rise buildings (less than 20 floors) with moderate traffic, an Mrl elevator would be more efficient and cost-effective.

Space Considerations:

-

If your building has limited space, an Mrl elevator is a great option as it does not need a dedicated machine room.

-

If space is not a constraint, and the building requires high-speed transportation, a Traction elevator would be more appropriate.

Energy and Environmental Goals:

-

If your goal is to cut energy consumption and lower the environmental impact, Mrl elevators may be the best choice, thanks to their regenerative drive systems and compact, energy-efficient motors.

Budget and Long-Term Costs:

-

Mrl elevators have lower upfront costs, but their long-term costs can be higher due to the specialized parts and service requirements.

-

Traditional Traction elevators have higher initial costs but may offer better flexibility maintenance and future upgrades, making them more cost-effective in the long run.

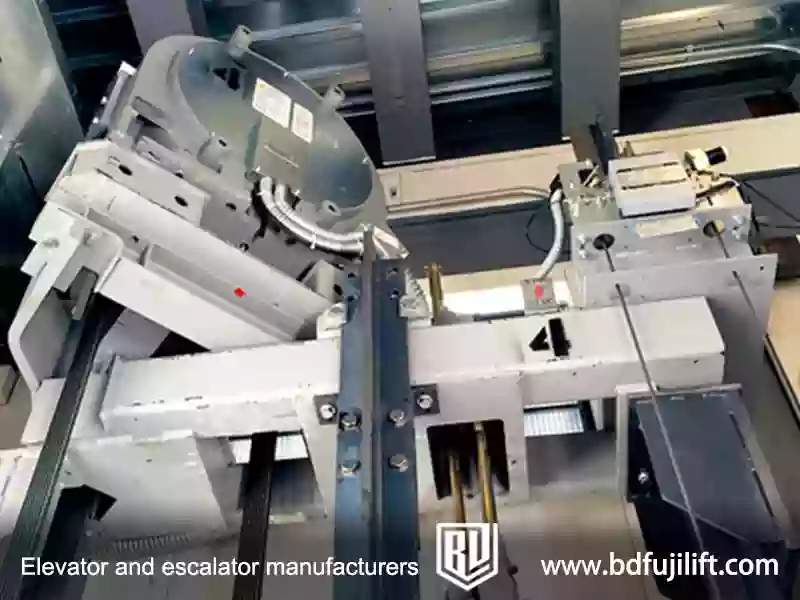

BDFUJI Manufactures High-Quality Elevators for You

At BDFUJI, we offer both Traction and Mrl elevator systems designed to fit the needs of your building.

Whether you need a fast elevator for a tall skyscraper or a space-saving option for an apartment building, we have the right technology and experience to make sure your elevator works smoothly and efficiently.

No matter how simple or complex your project is, we are here to help and provide the best solution.

Conclusion

In conclusion, Mrl elevators and Traction elevators differ in space, cost, energy use, performance, and long-term maintenance. The best choice depends on your building’s needs.

Mrl elevators are a good option for smaller or mid-sized buildings where space and cost are important.

Traction elevators are better for taller buildings that need faster speeds, more capacity, and can handle more traffic.

FAQ

What is the lifespan of an Mrl elevator?

An Mrl elevator typically lasts between 20 to 30 years, depending on the maintenance and usage. Regular servicing is crucial to ensure longevity.

What is the lifespan of a traction elevator?

Traction elevators generally have a lifespan of 30 to 40 years, with proper maintenance. They are known for their durability and long-term reliability.

What is the most efficient elevator system?

While both systems are efficient, Mrl elevators are generally more energy-efficient due to their regenerative drive systems and the absence of a machine room. However, for high-traffic or high-rise buildings, Traction elevators may be more efficient in terms of performance.