A hydraulic elevator is one of the most common types of elevators used in homes, stores, and small buildings. It moves people or goods between floors using a simple system of fluid and pistons.

If you’re thinking about adding an elevator to your building, a hydraulic elevator might be the right choice. But how does it work? How much does it cost? How high can it go?

In this guide, we’ll answer all your questions.

What is a Hydraulic Elevator?

A hydraulic elevator is a type of elevator that uses hydraulic fluid to move the elevator car up and down. It works by using a piston that is pushed by pressurized hydraulic fluid, which lifts the elevator car. This system is simple and reliable, making it a popular choice for low- to mid-rise buildings.

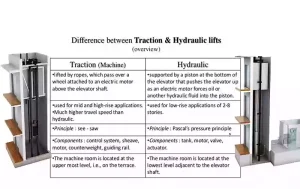

Hydraulic elevators are different from other types of elevators, like traction elevators, because they don’t use cables and pulleys. Instead, they rely on fluid pressure to lift the car. This makes them a great option for buildings where space for machinery is limited.

A Brief History of Hydraulic Elevators

-

1800s: Early elevators used ropes and steam power. They were slow and not very safe.

-

1870s: German engineer Gottlieb Daimler helped develop the first hydraulic system using water pressure.

-

1900s: Oil-based hydraulic elevators became more common. They worked better and were easier to control.

-

1950s: Many buildings started using hydraulic elevators for 2–6 floors because they were simple and cost less.

-

Today: Modern hydraulic elevators use advanced pumps and safety systems. They are still a popular choice for homes and small buildings.

Types of Hydraulic Elevators

In this guide, we will focus on the different types of hydraulic elevators commonly used in buildings. These elevators use hydraulic fluid and pistons to move the elevator car, making them reliable for various building types. Other elevator systems, like traction or pneumatic elevators, are also used in some buildings but are less common for low- and mid-rise buildings.

1. Conventional Hydraulic Elevators

Conventional hydraulic elevators are the most common type of hydraulic elevator. They use a piston powered by hydraulic fluid to lift the elevator car. The piston moves up and down inside a cylinder, pushing the car with it.

| Advantages | Limitations |

|---|---|

| Simple and easy to install. | Requires a deep pit for the piston. |

| Reliable and cost-effective. | More expensive to install than other types. |

| Ideal for low-rise buildings. | Limited to buildings with fewer than 5 stories. |

2. Hole-less Hydraulic Elevators

Hole-less hydraulic elevators work like conventional hydraulic elevators but do not need a deep hole in the ground. Instead, they use two pistons on either side of the car to lift it.

| Advantages | Limitations |

|---|---|

| No need for a deep hole or pit. | Not ideal for buildings taller than 5 floors. |

| Easier and cheaper to install. | May have a smaller weight capacity. |

| Good choice for older buildings. | May need more space on the sides for pistons. |

3. Double-acting Hydraulic Elevators

Double-acting hydraulic elevators use two pistons to lift the car—one below and one above. This gives the system more power and control.

| Advantages | Limitations |

|---|---|

| Can lift heavier loads. | Uses more hydraulic fluid. |

| Works well in taller buildings. | More complex and expensive to install. |

| Offers smoother and more stable rides. | Needs strong support structure. |

4. Ropeless Hydraulic Elevators

Ropeless hydraulic elevators use a special piston system to lift the elevator without any ropes or cables. This makes the ride smooth and quiet.

| Advantages | Limitations |

|---|---|

| No ropes or cables needed. | Not as widely available as other types. |

| Smooth and quiet operation. | Can be more costly to maintain. |

| Modern and clean design. | May need special parts or service. |

To Summarize

- Conventional hydraulic elevators are simple and low-cost, but they need a deep hole and work best in buildings with fewer than 5 floors.

- Hole-less hydraulic elevators do not need a deep hole. They are easy to install and good for older buildings with up to 5 floors.

- Double-acting hydraulic elevators are stronger and can lift more weight. They are used in taller buildings but cost more.

- Ropeless hydraulic elevators are smooth and quiet. They don’t use ropes or cables, but they are more expensive and not used as often.

How Much Does a Hydraulic Elevator Cost?

Use the table below to get a simple idea of how much different types of hydraulic elevators might cost. The prices are for a full system, including the elevator car, drive system, and basic installation. The cost can change depending on your building and location.

| Hydraulic Elevator Type | Estimated Cost |

|---|---|

| Conventional Hydraulic Elevator | $25,000 – $40,000 (Base price) |

| Hole-less Hydraulic Elevator | $30,000 – $45,000 (+10%–20%) |

| Double-acting Hydraulic Elevator | $40,000 – $60,000 (+50% or more) |

| Ropeless Hydraulic Elevator | $50,000 – $70,000 (+80% or more) |

How Does a Hydraulic Elevator Work?

A hydraulic elevator works using fluid, a piston, and a motor. These parts work together to move the elevator car up and down inside the shaft.

The Main Parts of a Hydraulic Elevator

A hydraulic elevator has three key parts:

The Elevator Car – This is where people or goods ride.

The Piston – A large metal rod that pushes the car up from below.

The Pump Unit – A motor that moves hydraulic fluid into the piston.

How It Works

Here is how a hydraulic elevator moves:

- The motor starts and pumps hydraulic fluid into the piston.

- The fluid pushes the piston up, and the piston lifts the elevator car.

- When the elevator reaches the right floor, the motor stops.

- To go down, the system lets the fluid slowly flow out of the piston.

- This makes the car go down smoothly by its own weight.

- Once the car reaches the ground, the fluid goes back into the tank, ready for the next ride.

This process is safe, smooth, and simple. It works well for low-rise buildings, like homes or small offices.

Hydraulic Elevator vs. Traction Elevator: What’s the Difference?

Hydraulic elevators and traction elevators are the two most common types of elevators. They both move people and goods between floors, but they work in different ways. Their differences can be seen in how they move, how much space they need, how much they cost, and which buildings they work best in.

Movement System

Both elevator types carry passengers between floors, but they use different systems to move.

A hydraulic elevator uses a piston filled with fluid to push the elevator car up from below. When going down, the fluid is released slowly so the car can lower safely. This system is smooth and simple.

A traction elevator uses ropes, counterweights, and a motor. The motor pulls the ropes to lift or lower the car. This system is more common in tall buildings because it is faster and more efficient for long travel distances.

Space Requirements

Hydraulic and traction elevators need different amounts of space.

A hydraulic elevator often needs a machine room at the bottom of the shaft and a hole in the ground for the piston. Newer models called MRL (machine-room-less) hydraulic elevators don’t need a separate room, which saves space.

A traction elevator usually needs space at the top of the shaft for its motor and pulley system. It doesn’t need a deep hole under the car, so it can be a better fit for buildings where digging is hard or expensive.

Cost and Maintenance

Cost and upkeep are important when choosing an elevator.

A hydraulic elevator usually costs less to buy and install. It’s easier to maintain and has fewer moving parts. But it uses more energy and hydraulic fluid, which can raise running costs over time.

A traction elevator costs more at the beginning and needs more frequent maintenance, but it uses less energy and may save money in the long run.

Best Use

Each elevator type fits different building types.

A hydraulic elevator is best for low-rise buildings, like homes, stores, and small offices. It is strong and can carry heavy loads, but it works better over short distances.

A traction elevator is better for mid- to high-rise buildings, like hospitals, hotels, and apartment towers. It moves faster, handles more floors, and provides a smoother ride for taller buildings.

How High Can a Hydraulic Elevator Go?

Hydraulic elevators are a good choice for low-rise and some mid-rise buildings. But they do have a height limit.

Most standard hydraulic elevators can travel up to 60 feet, or about 5 to 6 floors. This is because the piston that lifts the elevator can only go so far. Going higher would need a longer piston and a deeper hole in the ground, which makes the system harder and more expensive to install.

Some advanced hydraulic systems, like telescopic pistons or roped hydraulic elevators, can reach up to 75–90 feet. These are used in special cases where buildings are a bit taller but still don’t need a traction elevator.

For buildings taller than 7 or 8 floors, a traction elevator is usually a better choice. It doesn’t rely on a piston and can travel much higher without needing a deep pit.

How to Build a Hydraulic Elevator

Once you decide to install a hydraulic elevator, what’s next? In this section, we’ll guide you through the basic steps to plan and build one safely and correctly.

Step 1: Understand Your Building Needs

Before starting, you need to know what kind of elevator your building needs. Think about:

-

How many floors your elevator must travel

-

How much weight it should carry

-

Who will use it — people, goods, or both

These answers help you choose the right type of hydraulic elevator (like hole-less or conventional) and size.

You can ask an elevator expert or company to visit your site and check your building. This is called a site survey. It helps make sure the elevator will fit and meet local safety rules.

Step 2: Prepare the Space

A hydraulic elevator needs room for these parts:

-

The elevator shaft (where the elevator moves up and down)

-

A piston under or beside the shaft

-

A small machine room for the pump and oil tank

Your building may need some changes. Workers might dig a hole (for the piston) or build a frame for the shaft. They also need to make sure there is power nearby for the motor and controller.

Step 3: Choose the Elevator and Get a Quote

Now it’s time to choose the elevator. You can pick:

-

Standard models (faster to install, lower cost)

-

Custom models (more flexible in size and design)

Ask for quotes from 2–3 hydraulic elevator companies. They will tell you:

-

How much the elevator costs

-

What features are included

-

How long the project will take

Tip: A small home elevator usually costs $25,000 to $45,000. Bigger or custom ones may cost more.

Step 4: Install the Elevator

Once everything is ready, trained workers will install your hydraulic elevator. This step includes:

-

Installing the shaft and piston

-

Setting up the car and doors

-

Connecting the pump, fluid system, and controls

-

Testing safety systems

This process usually takes 4 to 8 weeks, depending on your building and the elevator size.

Step 5: Final Check and Inspection

After installation, the elevator must be tested. A licensed inspector checks that everything meets safety standards.

Once approved, your elevator is ready to use!

Conclusion

A hydraulic elevator is a smart and reliable choice for many buildings. It is strong, smooth, and cost-friendly — especially for homes, shops, and low-rise offices.

In this guide, you learned what a hydraulic elevator is, how it works, the different types, how high it can go, and how much it costs. We also showed you the steps to plan, build, and install one safely.

Before choosing an elevator, always think about your building’s needs, your budget, and how the elevator will be used. If you’re still unsure, talk to a trusted elevator company for advice.

With the right planning and support, your hydraulic elevator can bring safe and easy movement to your space for many years to come.

FAQ

1. Are hydraulic elevator cars the same size as traction elevator cars?

Yes, in most cases, the elevator car size can be the same. Both hydraulic and traction elevators can be made to fit standard dimensions. The size depends more on your building space and needs, not just the elevator type. You can ask your elevator supplier to match the size that works best for you.

2. Is a hydraulic elevator cheaper than a traction elevator?

Yes. A hydraulic elevator is usually cheaper to buy and install than a traction elevator. It has a simpler system and fewer parts, which helps lower the cost. But, it may use more energy over time. A traction elevator costs more up front but is more energy-efficient for taller buildings.

3. Does a hydraulic elevator have a backup battery, counterweight, or machine room?

-

Backup battery: Some hydraulic elevators can come with a battery backup to bring the car safely to the ground during a power outage.

-

Counterweight: No, hydraulic elevators do not use counterweights. That’s a key difference from traction elevators.

-

Machine room: Yes, most hydraulic elevators do need a small machine room, usually at the bottom of the shaft. Some newer models (MRL type) may not need a separate room.