Elevator pit waterproofing is essential for the normal operation of elevators, especially in high-humidity or underground environments.

Elevator pits are typically located underground and are prone to water accumulation. Prolonged moisture exposure can lead to the corrosion of elevator components, affecting safety and reducing the system’s lifespan. Therefore, implementing effective waterproofing measures is key to ensuring the safe operation of elevators and reducing maintenance costs.

We have gathered methods, testing verification techniques, and alternative solutions for elevator pit waterproofing from reliable data sources, including the web and elevator industry experts. Let’s dive in further.

What is Elevator Pit Waterproofing?

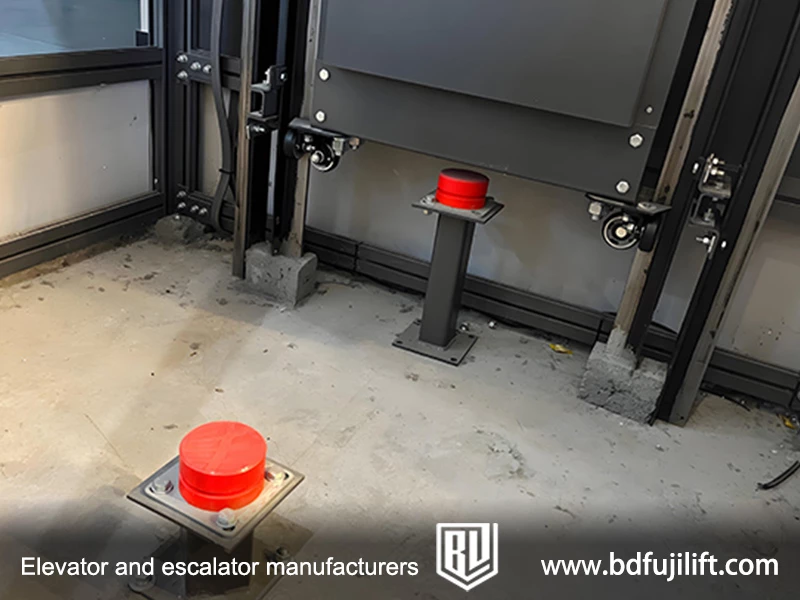

The elevator pit is the space located at the bottom of the elevator shaft. When the elevator reaches the lowest floor, the elevator car enters this area.

Elevator pit waterproofing involves applying materials or coatings to prevent moisture from entering the elevator shaft, ensuring the pit remains dry. This helps to avoid moisture damage to the elevator system, preventing safety issues and costly repairs.

Methods for Elevator Pit Waterproofing

Use Waterproof Coatings for Elevator Shaft Waterproofing

Waterproof coatings are commonly used to waterproof elevator shafts. They form a strong waterproof membrane on the shaft walls, preventing water penetration.

There are various types of waterproof coatings available on the market, such as polyurethane and epoxy resin coatings. These coatings are effective and ensure good adhesion to various surfaces.

Here’s the process for applying waterproof coatings:

- Surface Cleaning: First, ensure that the surface of the elevator shaft is clean and dry, removing any dust and grease. If the surface is uneven, sand it down to improve adhesion.

- Mixing the Coating: Mix the waterproof coating with a curing agent (if required) in the correct ratio, ensuring no bubbles form.

- Coating Application: Use a brush or spray gun to apply the waterproof coating evenly on the shaft walls, making sure each area is completely covered.

- Curing Time: After applying the coating, let it cure for 24 to 48 hours to ensure full solidification. Avoid exposure to moisture during this time.

- Effectiveness Check: Once dry, inspect the coating to ensure the surface is smooth and there are no cracks or peeling. Reapply if necessary.

This method is suitable for most environments, especially those with high humidity.

Use Waterproof Membranes for Elevator Shaft Waterproofing

Waterproof membranes are another common solution for elevator shaft waterproofing. They offer strong water resistance and durability, making them suitable for areas with high moisture risk.

Typically, waterproof membranes are applied to the exterior or underground sections of the elevator shaft to effectively prevent water from entering.

Steps for applying waterproof membranes:

- Surface Preparation: Clean the surface of the elevator shaft thoroughly to remove dust and grease. Ensure the surface is smooth for proper adhesion of the membrane.

- Choosing the Right Membrane: Select an appropriate waterproof membrane based on the environment of the elevator pit. Common types include PVC and modified bitumen membranes.

- Cut and Lay the Membrane: Cut the membrane to fit the shaft dimensions and lay it flat against the shaft walls, ensuring sufficient overlap between each section.

- Securing the Membrane: Use specialized adhesive or mechanical fasteners to secure the membrane firmly to the surface of the elevator shaft.

- Waterproof Test: After installation, perform a water test to check the tightness of the seams and the overall waterproofing effectiveness.

Waterproof membranes are ideal for environments with high water ingress and are easy to install, providing long-lasting protection.

Use Waterproof Sealant for Joints

For joints within the elevator shaft, using waterproof sealant is an effective waterproofing method. This is especially useful around elevator door frames or where pipes pass through the shaft.

Sealant effectively prevents water from penetrating through the joints, ensuring the overall waterproofing remains intact.

Steps for using waterproof sealant:

- Joint Cleaning: Clean the joints thoroughly to ensure there is no dust, grease, or moisture before applying the sealant.

- Choosing the Right Sealant: Select an appropriate waterproof sealant depending on the elevator shaft environment. Common options include polyurethane and silicone sealants.

- Applying the Sealant: Use a caulking gun to apply the sealant evenly along the joints, ensuring complete coverage.

- Smoothing the Sealant: Use a scraper to smooth the surface of the sealant, ensuring it is tightly bonded to the joints and preventing water penetration.

- Curing and Checking: Allow the sealant to cure for 24 to 48 hours. Once cured, inspect for any leaks to ensure the sealant has effectively blocked water entry.

Waterproof sealant is particularly useful around elevator door frames and pipe joints.

Elevator Pit Waterproofing Testing Methods

Water Infiltration Test

One of the most common methods for testing the waterproofing effectiveness of the elevator pit is the water infiltration test. This test uses water pressure to check for any penetration issues in the waterproof layer.

The steps for the water infiltration test:

- Preparation: Ensure the waterproofing layer is fully dry and cured. Check for any damage or gaps.

- Water Pressure Test: Use a water pressure device to simulate real-world conditions by injecting water into the elevator pit.

- Checking for Leaks: Observe for any signs of water leakage. If water seeps through the waterproofing layer, additional treatment is required.

- Document and Analyze Results: Record the test results and assess whether they meet the required standards.

Visual Inspection

Routine visual inspections are important for detecting potential waterproofing issues early.

During inspections, look for water stains, mold, or signs of corrosion, especially around joints and connections. Any abnormalities should be noted and addressed.

Using a Humidity Detector

Humidity detectors help monitor moisture levels in the elevator pit in real-time, which is useful for detecting water penetration early.

Steps for using humidity detectors:

- Install the Humidity Detector: Place the detector on the walls or floor of the elevator pit, ensuring it makes good contact with the surface to measure moisture accurately.

- Set Alarm Parameters: Set alarm thresholds to alert if humidity exceeds certain levels, indicating potential leakage.

- Monitor Humidity Levels: Regularly check the readings to ensure the moisture level stays within acceptable ranges. A rising trend could indicate water penetration.

- Record and Analyze Data: Track changes in humidity and investigate the cause if levels rise consistently, leading to necessary repairs.

Alternative Solutions When Waterproofing Is Not Feasible

In some cases, conventional waterproofing methods may not be feasible or may not completely resolve the problem. In such cases, elevator experts recommend the following alternative solutions:

Drainage Systems

Design an efficient drainage system to ensure that water can be quickly removed from the elevator pit, preventing water accumulation. A drainage system typically includes pipes, pumps, and filtration systems. Its main function is to guide water flow and avoid accumulation that could affect the elevator pit.

Implementation steps:

Open drainage channels along the walls or around the base of the elevator pit to guide the water flow smoothly.

Use appropriate drainage pipes to quickly remove water from the pit.

Equip with wastewater pumps to ensure that water can be removed automatically during high water levels.

Water Pump Systems

In areas with high water levels or frequent heavy rains, installing an automatic water pump system is another effective alternative. These systems automatically pump out water from the elevator pit to keep it dry, preventing moisture accumulation.

Implementation suggestions:

Choose the appropriate automatic pump based on the size of the elevator pit and the expected water levels.

When installing the water pump system, ensure that the pump’s capacity and drainage capability can handle the maximum expected water volume.

Although these alternative methods cannot fully resolve waterproofing issues, especially as drainage systems may not completely seal concrete foundations, they are still effective emergency solutions, especially in situations where other waterproofing measures are not feasible.

The Importance of Elevator Pit Waterproofing

Industry research shows that implementing waterproofing measures in elevator pits can significantly extend the lifespan of elevators.

Effective waterproofing reduces the frequency of elevator failures and helps lower maintenance costs.

It is estimated that, without waterproofing measures, elevator maintenance costs can increase by up to 15%-20% annually due to water damage. However, elevator pits with effective waterproofing measures can reduce annual maintenance costs by at least 10%.

Additionally, waterproofing significantly improves elevator safety. According to the International Elevator Association (IEC), water accumulation in elevator shafts is one of the most common causes of elevator malfunctions.

Particularly in humid environments, water damage to the electrical system of an elevator can pose serious safety risks to passengers.

Advantages and Disadvantages of Elevator Pit Waterproofing

We consulted with multiple elevator installation experts and building designers to summarize the advantages and disadvantages of elevator pit waterproofing:

Advantages

- Extended Elevator Life:Elevator shaft waterproofing effectively prevents moisture from damaging the elevator’s electrical systems, metal structures, and other components, thus prolonging its life.

- Reduced Maintenance Costs:Effective waterproofing minimizes water stains, mold growth, and corrosion, which in turn reduces maintenance costs and minimizes unnecessary downtime.

- Improved Safety:Waterproofing elevator pits prevents moisture from damaging elevator control systems, thereby lowering the likelihood of safety accidents caused by electrical faults.

Disadvantages

- High Construction Complexity:Waterproofing installation requires a professional team and may require partial modifications to the elevator pit, increasing construction costs and time.

- Higher Initial Investment:High-quality waterproof coatings and membranes can lead to higher initial costs, especially when retrofitting older buildings.

- Maintenance Requirements:Waterproofing materials require regular inspections and maintenance, as they may age or deteriorate over time, necessitating reapplication.

Elevator pit waterproofing not only impacts elevator safety but directly affects its service life and maintenance costs.

Implementing effective waterproofing measures reduces elevator failure rates, extends service life, and improves investment returns.

Take Immediate Action to Ensure Elevator System Safety and Durability

If you are looking for high-quality elevator systems and want to ensure that your elevator pit waterproofing is properly addressed, feel free to contact BDFUJI. As a global leader in elevator manufacturing, BDFUJI combines years of industry experience and innovative technology to provide custom elevator solutions. We ensure that every elevator system offers outstanding safety, reliability, and durability to help your building projects achieve optimal performance.

Recommended Reading: