It is completely possible to add an elevator to an old building.

The real question is how to do it in a way that is safe, practical, and not too expensive.

This depends on the type of elevator you choose and how you plan to install it.

This guide will show you the main types of elevators and the main ways to add them, so you can upgrade your building.

Which Elevator Works Best for Your Existing Building?

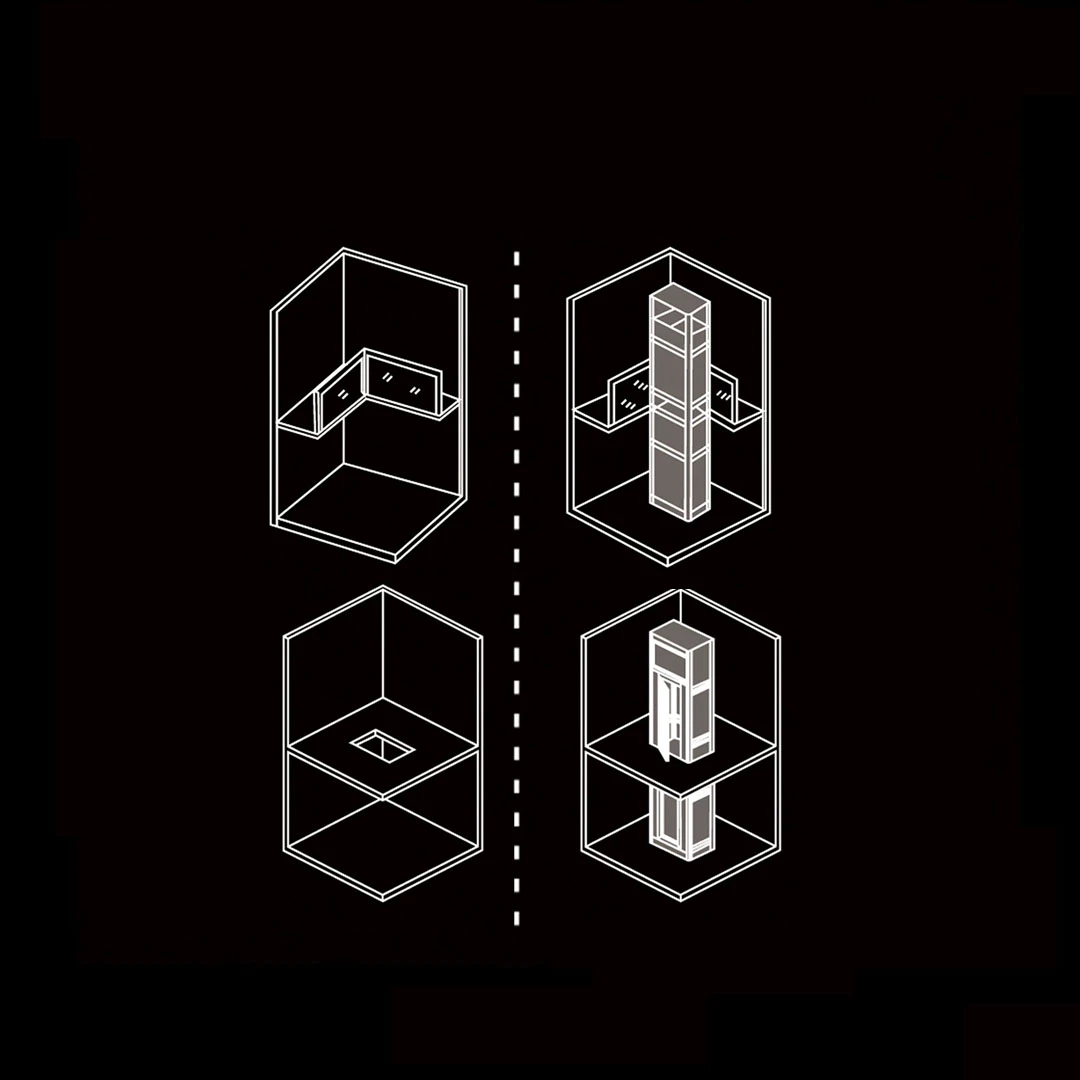

In an existing building, different types of elevators will change how much the building needs to be rebuilt. Some types need more work on the structure, and some need less.

For buildings with up to 6 floors, a machine-room-less traction elevator (MRL) is usually the first choice.

Compared with other types of elevators, it saves more energy, runs faster and more smoothly, and can handle more people every day. It can also meet stricter safety and building standards and helps increase the value of the property.

Most MRL traction elevators come with their own shaft and do not need a very deep pit. This means less construction work, so they are easier to install in existing buildings.

For owners who care about comfort, resale value, and long service life, an MRL traction elevator is a space-saving and cost-effective solution. This is why elevator suppliers like BDFUJI focus on modern traction elevators for most residential and commercial retrofit projects.

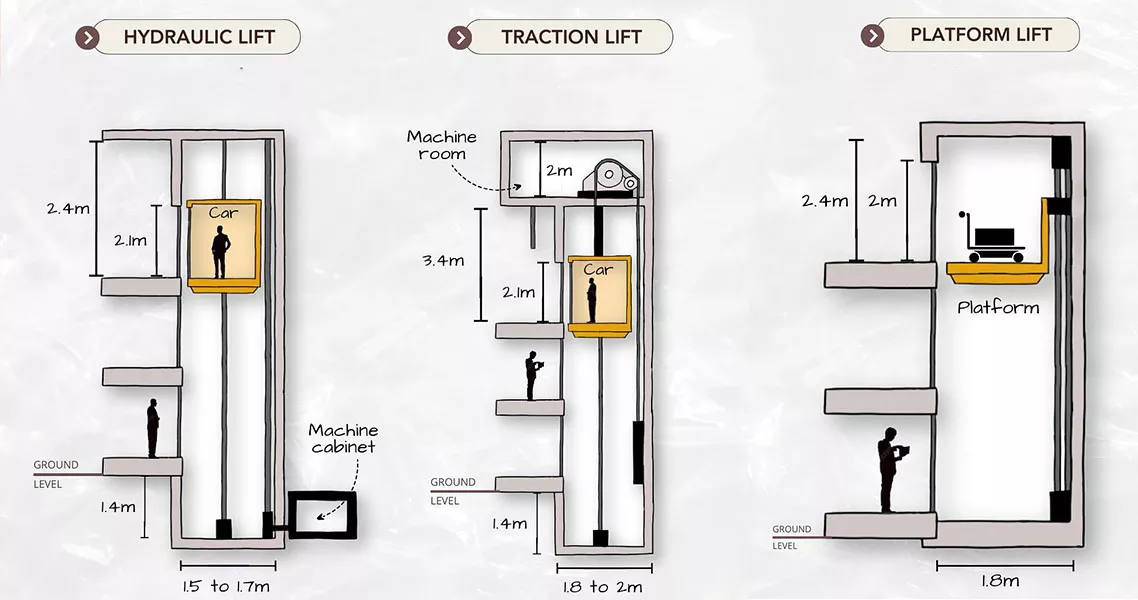

A hydraulic elevator is driven by a cylinder under the car.

This design is more flexible at the top of the shaft and does not need much space above, but it does need enough space on the ground floor for the cylinder, oil tank, and pump unit.

When the building has only a few floors, the traffic is not very heavy, and the ground floor is easier to rebuild than the top floor, a hydraulic elevator can be a workable solution. For taller buildings or projects with a lot of people, it is usually not the best choice.

A screw-driven platform lift can help reduce construction work for existing buildings with about two to six floors and low traffic.

The drive system of a screw-driven lift is installed inside the shaft, usually inside a light steel or aluminum structure that arrives on site as one complete unit. It needs very little work on site and has low requirements for pit depth and top space. In many cases, it can avoid heavy cutting of floors and beams, so it has less impact on the building and needs less construction work.

However, this type of lift runs at a lower speed, the car is smaller, and it is only suitable for private homes or very light use.

Benefits of Adding an Elevator to an Existing Building

1.Easier travel for everyone

An elevator makes it easier for seniors, children, people with disabilities, and anyone with bags, strollers, or luggage to move between floors.

2.Increase property value

Buildings with elevators are seen as more modern and comfortable, so owners can usually charge higher rent and ask for a better selling price.

3.Easier to sell and rent

For many buyers and tenants, “no elevator” is a deal breaker, especially on higher floors, so adding a lift helps keep the building on their short list.

4.Longer life for the building

With an elevator, residents can stay in the building as they get older, and the property stays attractive and useful for many more years.

5.Better compliance with rules

In some public and commercial buildings, an elevator is needed to meet accessibility laws and standards, and to provide fair access for all users.

6. Stronger image for the building

Adding an elevator shows that the owner is willing to invest in comfort, safety, and long-term value, which improves the project’s image in the market.

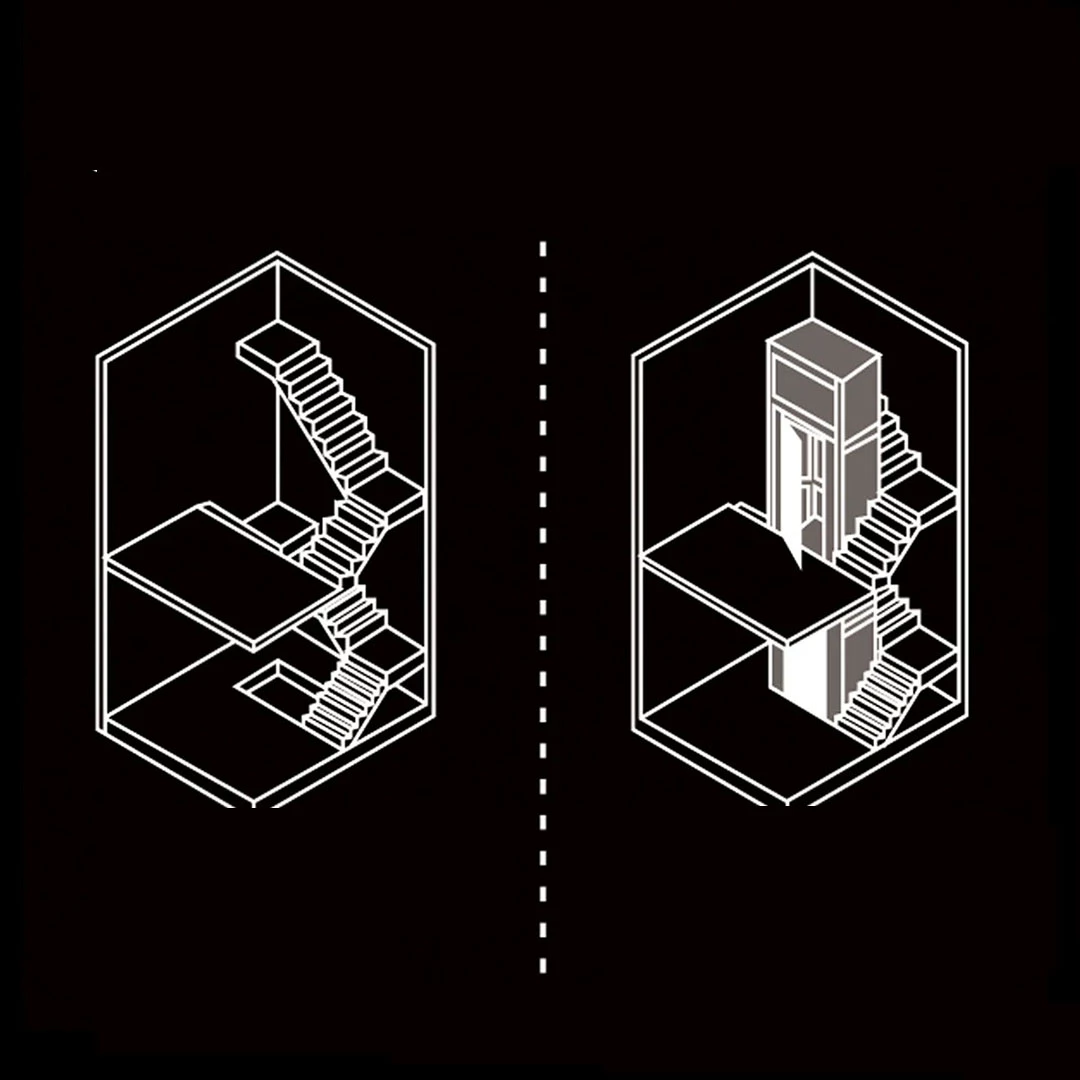

3 Main Ways to Add an Elevator to an Old Building

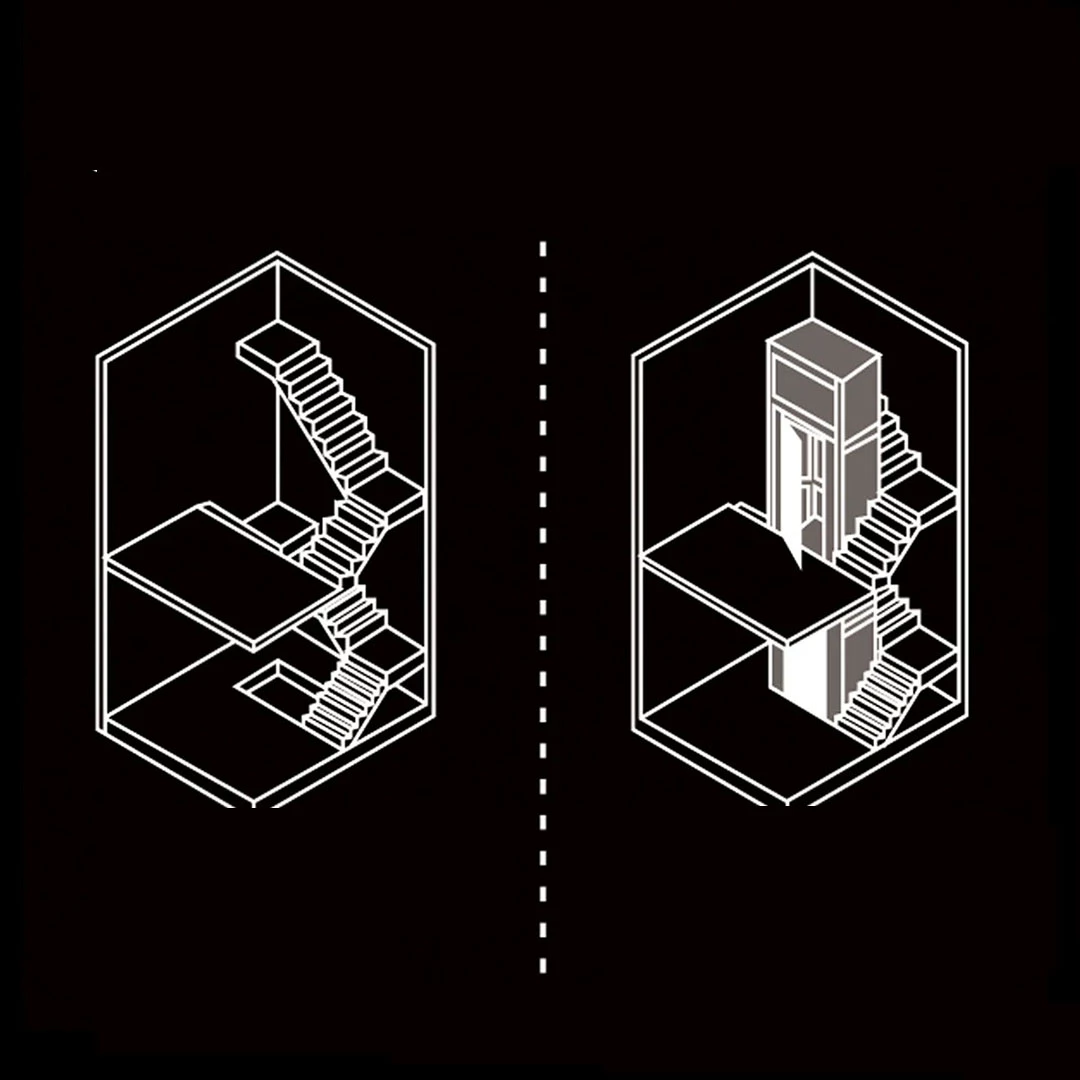

Using the stairwell space

Many buildings have empty space in the middle or beside the staircase. We can use this space to install the elevator, making the most of the available area. This option also saves the cost of cutting floors and other construction work, helping to reduce the overall elevator cost.

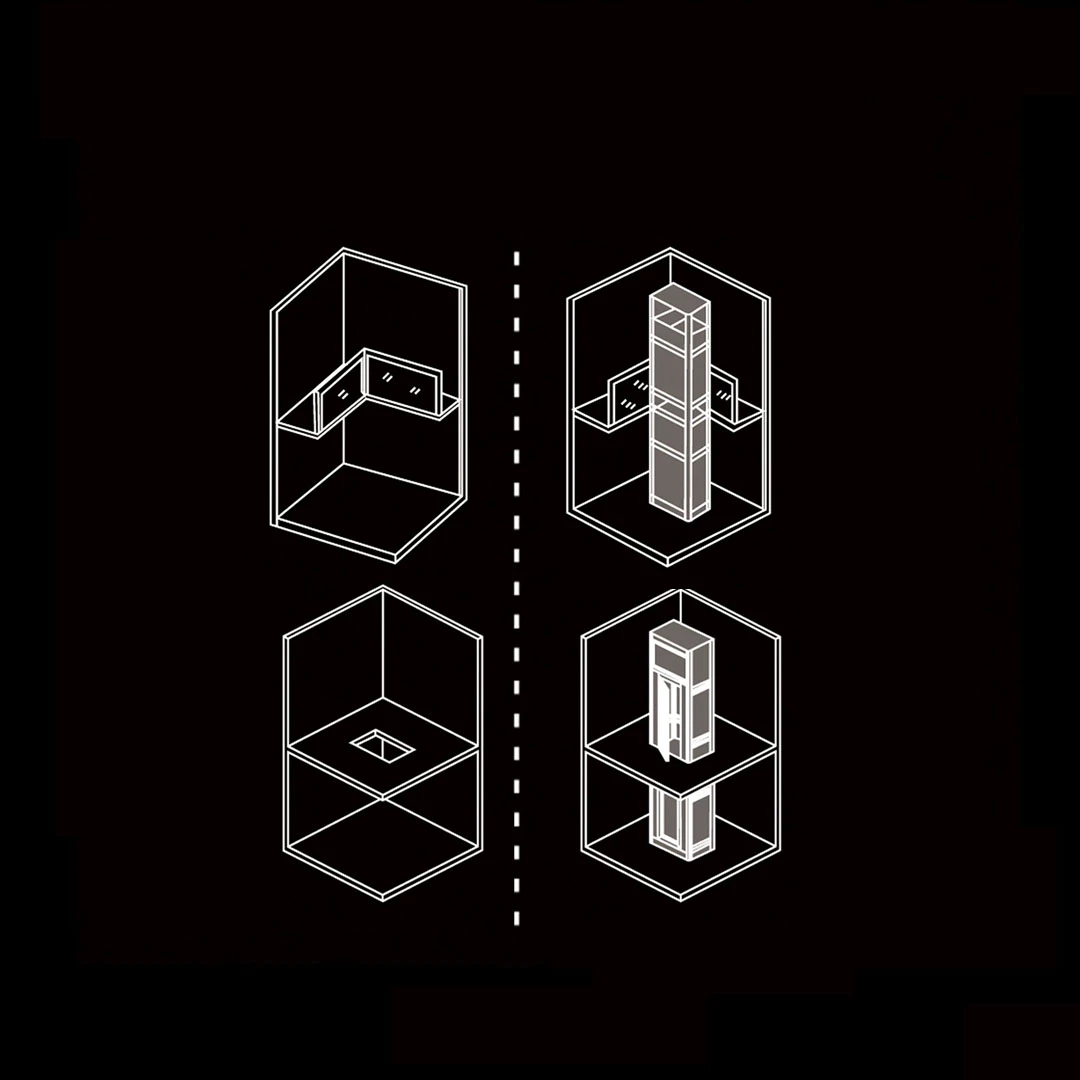

Atrium Installation

If the building has an open hall, the elevator can be installed in the hall. If there is no space available, we can cut some space in the floor slabs to install the elevator. When the right elevator is chosen, it not only adds convenience to the building but also enhances the design of the home.

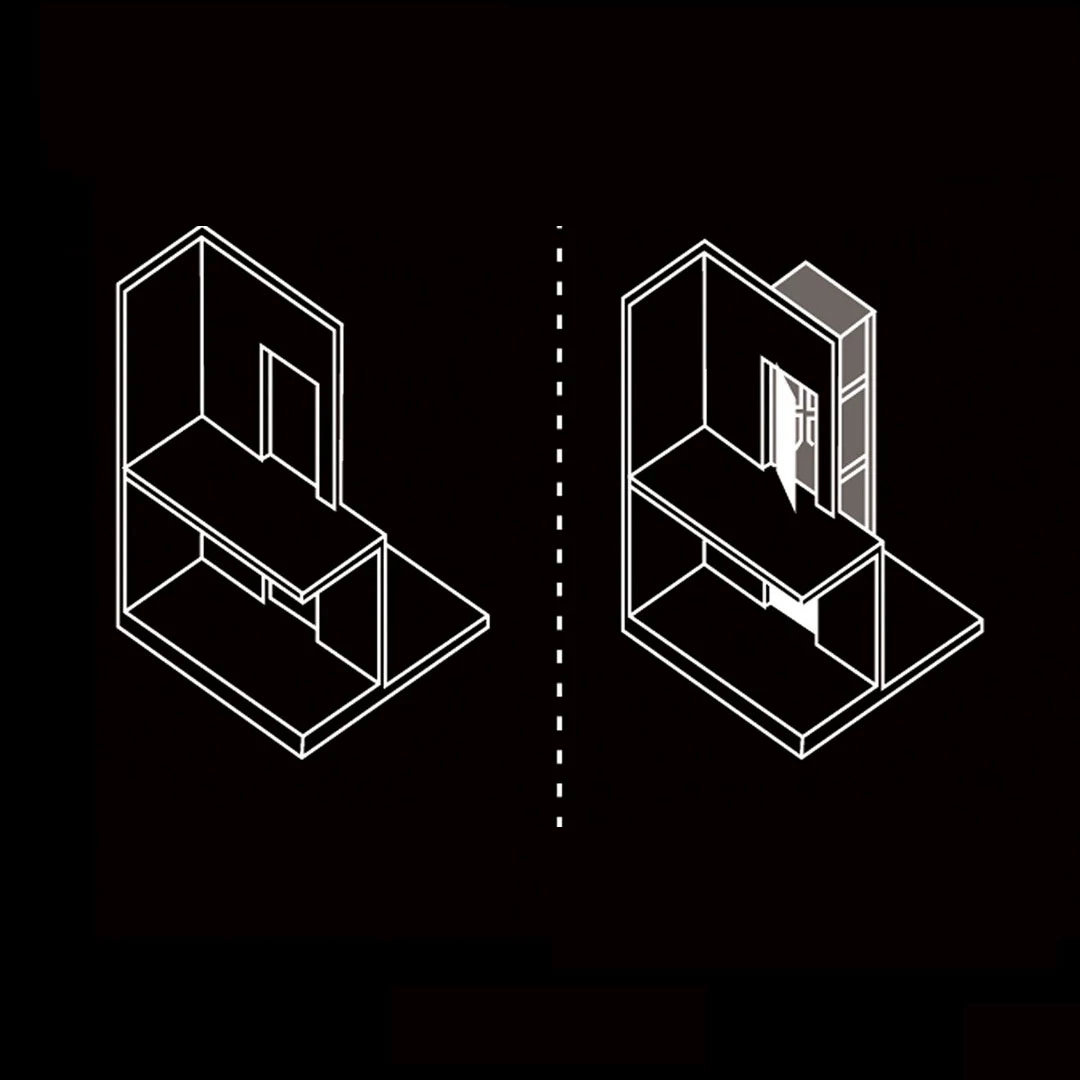

Outdoor Installation

If the building has an open hall, the elevator can be installed in the hall. If there is no space available, we can cut some space in the floor slabs to install the elevator. When the right elevator is chosen, it not only adds convenience to the building but also enhances the design of the home.

Elevator Installation Process in Existing Buildings

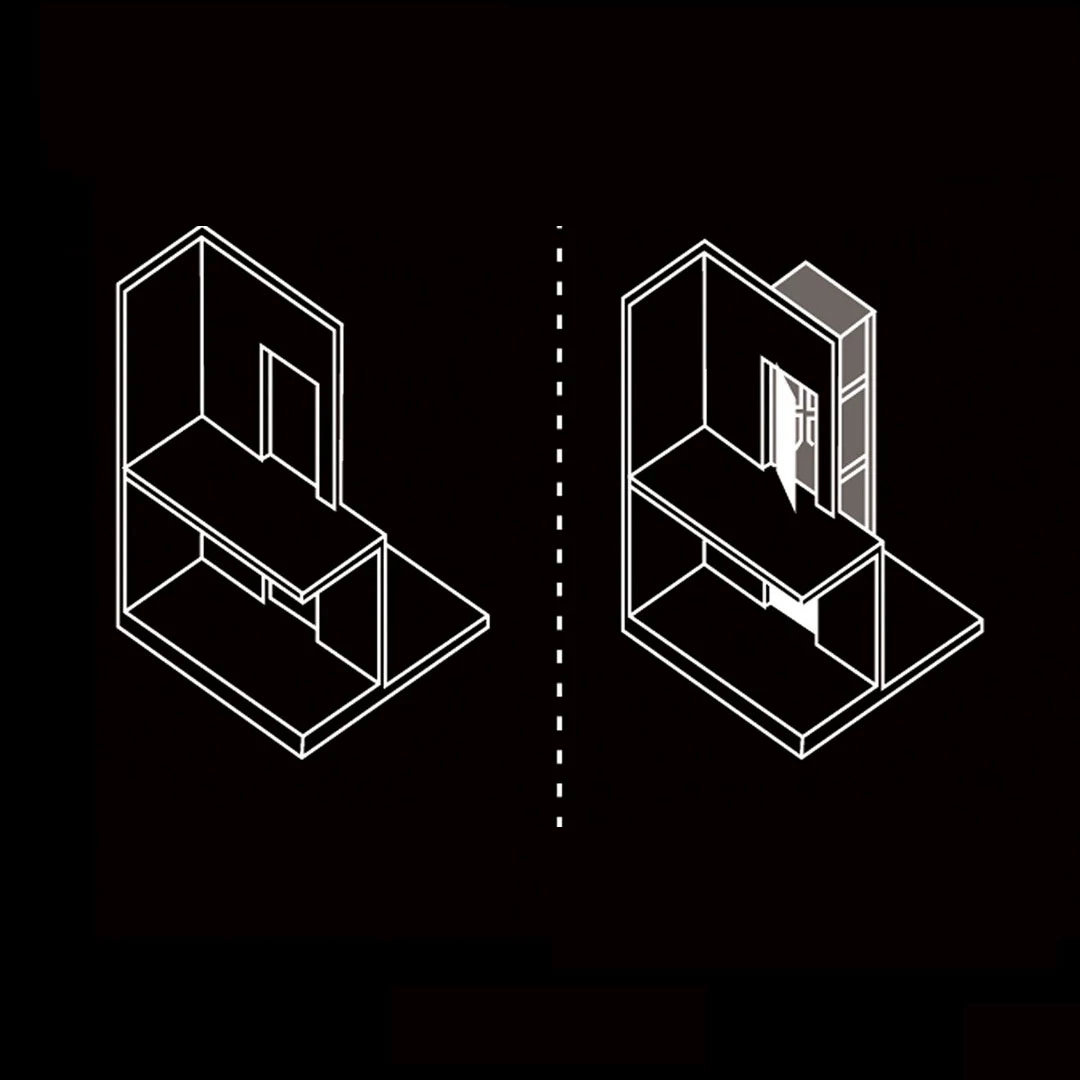

Stairwell Elevator Installation Process

Excavation of the Pit

Identify the location for the elevator shaft and dig the pit. If necessary, reroute any underground utilities.Remove Handrails

Take off any handrails or obstacles and install safety barriers to ensure a safe work environment.Structural Enclosure

Build the enclosure around the shaft, paying special attention to keeping the staircase’s appearance and ensuring it meets any necessary safety or aesthetic requirements.Elevator Assembly

Assemble the mechanical parts and complete the electrical connections for the elevator.Finishing Touches

Install handrails if needed, paint, replace light fixtures, clean the work area, and test the elevator.

Atrium elevator installation process

- Layout, Excavation, and Foundation

Prepare the building’s layout, plan the space for the elevator, check pipe locations, and begin excavation for the foundation. - Facade Openings

Modify any necessary areas, create openings for the elevator shaft and doors, and start constructing the elevator shaft. - Building the Structure and Scaffolding

Assemble the scaffolding and install any safety measures to support the construction. - Window Installation

Install windows, and set up the ventilation system. - Electrical and Elevator Assembly

Install electrical wiring and lighting, assemble the elevator structure, and install the motor and mechanical components. - Completion

Apply paint, clean the work area, test the elevator, and hand over the completed project.

Outdoor elevator installation process

When installing a new elevator on the facade or in the courtyard, the stairs often need to be modified to align with the platform on each floor.

Layout, Excavation, and Foundation

Similar to the previous steps, plan the layout, identify pipe locations, and begin excavation for the foundation.Building Structure and Scaffolding

Set up scaffolding for safety and construct the necessary structural supports for the elevator.Building the Tower Enclosure

Remove any needed sections of the building, construct the elevator shaft, and install the framework and windows.Remove Old Stairs and Build New Ones

Demolish old stairs, modularly build the new stairs, construct new platforms, and install railings.Electrical and Elevator Assembly

Complete electrical installation and lighting, assemble the elevator structure, install the motor and mechanical parts, and complete the elevator assembly.Completion

Paint, finish the area, clean up the site, perform final testing, and hand over the project.

FAQ

Installing an Elevator in an Existing Building

Do I need

planning permission to install an elevator?

Yes, in most countries, you need planning permission to install an elevator. It is recommended to contact your local government or elevator installation team before starting the project for detailed guidance.

How long does

it take to install an elevator?

The installation time for an elevator depends on the type of elevator, building conditions, and project size. Below are typical installation time ranges and the main factors that affect the schedule.

Typical Installation Times

New construction, traction or hydraulic passenger elevator (mid-rise, 4-12 floors): 6-12 weeks from shaft preparation to commissioning.

New high-rise traction elevator (20+ floors, machine room or machine room-less, complex control systems): 3-6 months.

Hydraulic elevator (low-rise, 2-6 floors): 4-8 weeks.

Machine-room-less elevator (MRL): Typically takes 6-10 weeks (depending on shaft preparation).

Modernization (complete replacement of the car, doors, controller, and equipment in the existing shaft): 3-8 weeks if the shaft and pit are in good condition; over 12 weeks for large-scale structural changes.

Door or controller upgrades only: 1-2 weeks.

Freight elevator (heavy-duty): 8-16 weeks depending on capacity and structural reinforcement needed.

Residential/home elevators (no shaft or small lift): Modular systems take 1-3 weeks; custom installations take longer.

How much space

do I need to install an elevator?

The amount of space needed depends on the type and model of the elevator you choose.

For example, our smallest model requires a minimum opening size of 1000×993 mm, with a platform size of 600×830 mm. This means it can fit into tight spaces, like a small closet.

On the other hand, our largest freight elevator requires an opening size of 1895×2610 mm and a platform size of 1405×2480 mm. While this takes up around 5 square meters of space, it can carry heavy loads like a full pallet truck or up to 8-10 people.

All our elevators use a traction drive system, and for buildings with fewer than 6 floors, we typically use an MRL design, meaning the mechanical parts are inside the shaft (no separate machine room is needed). This compact system saves space, and you don’t need extra height or deep pit space. We only require a clear height of 2300 mm (for the top floor) and a shaft depth of 0-130 mm (with a ramp provided for a 0 mm shaft depth).

Suggestions for Choosing an Elevator for Existing Buildings

Finally, choosing an elevator for an existing building depends on the available shaft space, the number of floors, and your budget. Here are some general guidelines based on these factors:

If you have ample shaft space and want to save energy while ensuring smooth operation, a traction elevator is the ideal choice. Specifically, the MRL traction elevator, which doesn’t require a machine room, can be more easily integrated into the building.

If shaft space is limited and you need a more cost-effective solution, a hydraulic elevator might be a good option. Compared to traditional traction elevators, hydraulic elevators take up less space and are easier and faster to install, though they may have higher long-term maintenance costs.

If your budget is tight and space is limited, a screw-driven elevator could be a great choice. It has a compact design, is affordable, and requires very little space to install. However, it is only suitable for buildings with up to 6 floors and has the slowest speed among the three options, making it less suitable for high-traffic areas.

We hope this information helps! For more details or advice about BDFUJI elevators, please feel free to contact us using the form below. We’re happy to assist you!