The depth of an elevator pit is one of the critical parameters in elevator design. While many people may not pay attention to this issue, the pit’s depth directly impacts the operation of the cushioning system and the overall stability of the elevator. So, how deep should an elevator pit be? Is there a standardized depth? How do factors like elevator type, building height, and usage requirements influence the determination of the pit depth?

What Is an Elevator Pit?

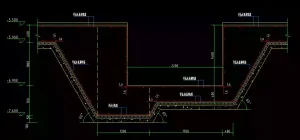

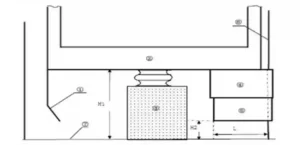

An elevator pit is the space at the bottom of the elevator shaft, designed to house the elevator’s cushioning devices and provide room for the elevator car to descend. The smooth operation of the elevator in both normal and emergency situations depends on the depth of the pit and the design of the cushioning system. The pit’s role not only affects the elevator’s safety but also has a direct impact on the overall performance of the elevator system.

Functions of an Elevator Pit:

-

Safety: The pit provides the necessary space for the cushioning devices, allowing them to absorb impact when the elevator car reaches the bottom of the shaft, thus preventing mechanical failures or overload accidents. According to the Elevator Safety Code (GB 7588-2003), the installation of the elevator buffer must effectively prevent damage to the elevator and passengers from bottom impacts, ensuring passenger safety.

-

Support for Elevator Operation: The depth of the pit directly influences the elevator’s stability and operational efficiency. A well-designed pit ensures smoother operation, reduces friction, conserves energy, and extends the elevator’s service life.

The design of the elevator pit is a crucial technical issue in elevator installation, as it directly impacts the elevator’s safety and efficient operation. For more detailed information on the specific requirements of pit design, you can refer to my other article: What is an Elevator Pit.

Standard Depth Requirements for Elevator Pits

The standard depth of an elevator pit typically ranges from 1 meter to 2.5 meters, but the actual depth can vary depending on the elevator type, building requirements, and installation standards. Different countries and regions may have their own elevator safety and building codes, so it’s essential to determine the pit depth according to local market needs.

Key Factors Influencing Elevator Pit Depth:

-

Hydraulic Elevators: Hydraulic elevators generally require a deeper pit, typically between 1.5 meters and 2 meters. The hydraulic system needs additional space to house the hydraulic pump and cylinder.

-

Traction Elevators: The pit depth for traction elevators usually ranges from 1.2 meters to 1.5 meters. Traction elevators use steel cables and counterweight systems, so they require less space and have a shallower pit depth.

-

Machine-Room-Less Elevators (MRL): These elevators, designed to save space, typically have a shallower pit, usually between 1 meter and 1.2 meters. This design eliminates the need for a separate machine room, making it ideal for low-rise buildings and reducing construction costs.

U.S. Standards Reference:

According to the ASME A17.1 code for elevator and escalator safety, the pit depth must meet specific safety requirements. For example, the code specifies that for hydraulic elevators, the pit depth should be at least 1.5 meters, while for traction elevators, it should not be less than 1.2 meters. The U.S. code also emphasizes that the elevator’s cushioning system must be capable of preventing excessive sinking of the elevator car under various operating conditions, ensuring passenger safety.

Differences Between Low-Rise and High-Rise Buildings:

In high-rise buildings, elevators must bear larger loads and operate at higher speeds, which usually requires a deeper pit. In these buildings, the elevator pit depth must take into account factors such as passenger load, speed, and emergency stop requirements. Consequently, the pit depth in high-rise buildings often reaches up to 2.5 meters.

Design Considerations for Elevator Pit Depth

The design of the elevator pit is influenced not only by the elevator type but also by factors such as building structure, load requirements, and elevator usage. These factors must be carefully considered to ensure the elevator system’s safety and efficiency.

-

Elevator Type: Different elevator types have significantly different pit depth requirements. Hydraulic elevators need deeper pits, while traction and machine-room-less elevators require shallower ones.

-

Building Structure: The number of floors and the total height of the building directly affect the elevator shaft design, which in turn impacts the pit depth. High-rise buildings, with larger load requirements, typically require deeper pits to maintain system stability.

-

Load Requirements and Usage: Elevators with high load capacities (such as freight elevators) require deeper pits, while those designed for specific uses (e.g., hospital elevators) may need additional space to accommodate frequent heavy use.

Common Pit Depth Design Errors

Designing an elevator pit is a complex process, and many designers make common mistakes along the way:

-

Overlooking Elevator Type Differences: Different elevator types have different pit depth requirements. Ignoring these differences can lead to incompatible designs. For example, if the pit depth is too shallow for high-load elevators, the elevator may not be able to absorb enough impact force, increasing the risk of malfunctions.

-

Incorrect Pit Depth (Too Shallow or Too Deep): A pit that is too shallow can destabilize the elevator, while one that is too deep wastes space and adds unnecessary construction costs. Studies show that approximately 30% of buildings have elevator pits that are too deep, leading to significant cost inefficiencies.

-

Lack of Coordination with Building Structure: The pit design must be coordinated with the building’s structural layout to avoid mismatches between the shaft and pit. Failure to do so can cause construction delays and additional repair costs.

How to Measure and Determine Elevator Pit Depth

When determining the depth of an elevator pit, designers must follow several key steps:

-

Consult the Manufacturer: Each elevator system has standard pit depth requirements. Manufacturers provide specifications and recommendations to ensure the pit depth meets the elevator’s needs.

-

Collaborate with Engineers: Work with structural and mechanical engineers to ensure the pit design aligns with the building’s structural requirements and the elevator system’s operational needs.

-

Follow International Standards: Pit design must comply with relevant building and elevator safety standards, such as ISO 25745 and ASME A17.1, to ensure safe operation.

By following these steps, designers can ensure accurate pit depth measurements, enhancing the elevator’s safety and functionality.

How to Measure and Determine Elevator Pit Depth

When determining the depth of an elevator pit, designers should follow these steps to ensure accuracy:

-

Consult with the Manufacturer: Each elevator system has standard pit depth requirements. Manufacturers will provide relevant design specifications and recommendations. Consulting with the manufacturer ensures that the pit depth will meet the specific needs of the elevator system.

-

Collaborate with Engineers: Work closely with structural and mechanical engineers to ensure that the pit design aligns with the building’s structural requirements and the operational needs of the elevator system.

-

Follow International Standards: The design of the elevator pit must comply with relevant building and elevator safety codes, such as ISO 25745 and ASME A17.1, to ensure safe and effective operation.

By following these steps, designers can ensure accurate pit depth measurements, leading to improved safety and functionality of the elevator system.

FAQ

Can the Depth of an Elevator Pit Be Customized?

Yes, the depth of the elevator pit can be customized based on the type of elevator and the requirements of the building. However, it must still adhere to relevant safety standards.

What Problems Does a Shallow Elevator Pit Depth Cause?

A shallow elevator pit can result in an unstable elevator system. The cushioning system may fail to absorb sufficient impact forces, leading to increased safety risks and potential damage to the elevator components.

Is There a Standardized Pit Depth for All Elevators?

No, different types of elevators have different pit depth requirements. Therefore, there is no one-size-fits-all standard depth for all elevators.