On July 15th, 1853, Elisha Otis invented the safety elevator, making tall buildings practical. Since then, traction elevators have become the most common type used in offices and homes. But how exactly does a traction elevator work?

What is a Traction Elevator?

A traction elevator is one of the most common elevator types in modern buildings. It works by wrapping steel ropes over a large wheel called a sheave. The ropes connect the car to a counterweight. The counterweight helps balance the car so it can move up and down more easily.

The motor turns the sheave, pulling the ropes so the car rises or falls. The system runs smoothly and is well suited for tall buildings that need fast and quiet service. Compared with other elevator types, traction elevators often use less energy and move faster. This makes them a trusted choice for offices, hotels, and apartment buildings.

Basic Working Principle of a Traction Elevator

A traction elevator moves when an electric motor turns the sheave. The ropes wrap around the sheave and link the car on one side with the counterweight on the other. When the motor turns, the ropes grip the sheave, making the car rise as the counterweight drops, or fall as the counterweight rises.

This balance makes the system both efficient and safe. In most homes or apartments, the car runs at about 1–3 meters per second, while in tall office towers it can travel much faster.

Traction Elevator Operation Process

When a passenger presses a button, the control system chooses the direction and distance. The motor then powers the sheave, pulling the ropes and starting the car. The car speeds up smoothly, then moves at a steady pace. As it nears the chosen floor, the motor slows the car so it stops gently. The brake locks the car, and the doors open. This cycle—start, speed up, run, slow down, and stop—repeats every trip to keep service safe and consistent.

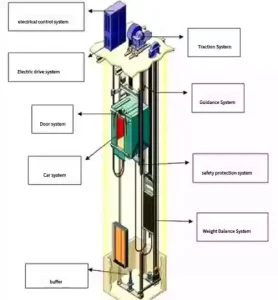

Core Components of a Traction Elevator

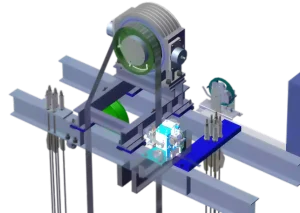

Traction Machine

The traction machine is the main power unit that drives the system. It includes the motor, brake, gearbox, sheave, and base. When the motor turns, the sheave grips the ropes and moves both the car and the counterweight. There are two main types:

-

Geared traction machines use a gearbox to slow the motor speed. They are common in mid-rise buildings.

-

Gearless traction machines connect the motor directly to the sheave. They run smoother and faster, which is better for high-rise towers.

In simple terms, the traction machine works like the engine and transmission of a car, but designed to lift people safely in a vertical shaft.

Ropes and Sheave

At the top of the shaft, the ropes and sheave connect the car to the counterweight. They use 6 to 8 steel wire ropes wrapped tightly around the sheave. The friction between them transfers the motor’s force to move the car up and down. Safety rules say that a single rope must be strong enough to carry the full weight of the car plus its largest load. Every elevator must use at least four ropes. Because of this design, the chance of all ropes breaking at the same time is very small, so the car stays safely supported.

Counterweight

The counterweight is placed on the opposite side of the car inside the shaft. Its main role is to balance the car’s weight so the motor does not have to work as hard. By carrying part of the load, the counterweight makes the system more efficient and lowers energy use. It also increases safety by helping prevent the car from free fall if the motor stops working. This practical role of the counterweight can be shown in a simple formula:

Formula for calculation: Counterweight = Car weight + (Load × Factor)

To give a simple example, if the car weighs 1000 kg and the rated load is 1000 kg, with a factor of 0.45, the counterweight should be 1450 kg. This balance lowers energy use and ensures steady, safe travel.

Guide Rails

Guide rails are made of strong steel profiles that can handle heavy pressure. They are installed along the inside walls of the elevator shaft and run from the bottom to the top of the shaft. Their job is to keep the car and the counterweight moving straight up and down without swaying. In an emergency stop, the guide rails also give the safety gear a solid surface to clamp onto.

Brake

The brake is mounted on the traction machine and is one of the most important safety parts of the elevator. It works with heavy steel arms and brake pads that press tightly against the brake wheel. When the car is at rest, springs push the pads closed so the car cannot move. When the motor runs, electrical power pulls the springs back and opens the pads so the car can travel. If the power is cut or an emergency stop is needed, the springs quickly force the pads shut again, clamping the wheel and stopping the car firmly in place.

Safety Mechanisms of a Traction Elevator

The safety of a traction elevator is built on systems that work together. Each device has a clear role, and every part is carefully designed to support the others. If one system fails, another will take over to keep the car safe. Below we examine the key safety mechanisms in traction elevators:

Overspeed Protection

The governor is a mechanical device that monitors the speed of the car. If the car moves faster than 115% of its rated speed, the governor activates the safety gear. The safety gear then clamps onto the guide rails and forces the car to stop. This principle was first shown by Elisha Otis in 1853 and remains the foundation of elevator safety today.

Buffers

Buffers are installed at the very bottom of the traction elevator shaft. They are made of materials such as polyurethane or hydraulic cylinders. When other safety devices fail to stop the car, buffers act as the last line of protection. They slow down the car and reduce the impact, protecting both the equipment and the passengers.

Elevator Door System

The elevator door system is mainly designed to make sure passengers are never exposed to an open shaft while the elevator is running. Under normal conditions, both the car door and the landing door must be fully closed and locked before the elevator can start. During maintenance, but, technicians may bypass the door circuits to make the car easier to control. If the bypass is not removed after servicing, the elevator may fail to detect whether the doors are open or closed and could move while the doors are still open, trapping or injuring people. Many fatal accidents have been linked to this problem, which shows why the door system is one of the most critical safety mechanisms in traction elevators.

Electrical & Rescue Systems

The electrical and rescue systems are designed to protect passengers in unusual conditions such as power cuts or equipment failures. Elevators have alarms and intercoms that allow people inside the car to communicate with building staff or rescuers even when power is lost. Rescue devices, such as a manual brake release or a handwheel, let trained staff move the car slowly to the nearest floor so passengers can exit safely. Besides, emergency stop switches are placed inside the car and in the machine room. These switches cut off power immediately and bring the car to a halt when activated.

Advantages of Installing a Traction Elevator

-

Energy-saving: The counterweight reduces the load on the motor, which means less electricity is needed for each trip.

-

Smooth ride: Steel guide rails keep the car stable and reduce both sway and noise, giving passengers a steady ride.

-

Safety: Protection comes from several devices working together, including the brake, governor, safety gear, and buffers.

-

Easy service: The mechanical layout is straightforward, so inspections, part replacements, and repairs can be carried out more quickly.

-

High capacity and speed: Traction elevators can carry heavier loads and reach higher speeds compared with hydraulic elevators, making them suitable for tall buildings.

Limitations of a Traction Elevator

-

Space requirements: A traction elevator needs a wider shaft and often a separate machine room. This can be a challenge in existing buildings with limited space.

-

Construction demands: The building structure must be strong enough to support the guide rails, counterweight, and machine room equipment. This increases design and construction complexity.

-

Initial cost: The installation cost is higher compared to small hydraulic elevators because of the extra components and structural needs.

-

Maintenance: While traction elevators are reliable, the ropes, sheave, and machine parts need regular inspection and replacement, which can add to long-term operating costs.

-

Noise and vibration: Although generally smooth, traction elevators can generate more noise or vibration compared to hydraulic systems, especially if not installed or maintained properly.

Conclusion & Safety Reminders

A traction elevator is safe because it uses several protective systems working together, including the counterweight, ropes, brake, governor, and buffers. These devices create layers of defense that keep the car stable and passengers protected in both normal and emergency conditions.

For passengers, the key reminder is not to jump, kick, or tamper with anything inside the car. For technicians, it is critical to restore all circuits and locks after maintenance so that safety logic is never bypassed.

When designed properly and maintained on schedule, traction elevators provide dependable service and stand among the safest machines used in daily life.

FAQ

What is the difference between a traction elevator and a hydraulic elevator?

A traction elevator uses ropes and a motor to move the elevator car up and down. It works well for tall buildings and moves smoothly and quickly. A hydraulic elevator uses a piston and fluid to push the elevator up. It is slower and usually used in low-rise buildings. Traction elevators are more energy-efficient and faster than hydraulic elevators.

How do you calculate the length of the ropes for a traction elevator?

The length of the ropes depends on the height the elevator will travel and the design of the system. Generally, the ropes need to be twice the height of the elevator shaft plus some extra length for wrapping around the wheels. Professionals use precise measurements to make sure the ropes fit safely and work correctly.

What is a permanent magnet synchronous elevator traction machine?

A permanent magnet synchronous (PMS) traction machine is a type of motor used in modern traction elevators. It uses magnets to create strong, efficient power with less energy use. PMS machines are smaller, quieter, and more reliable than traditional motors. They help make elevators faster and save electricity.