In a hospital, every second counts. When a patient is rushed from the emergency room to the operating room, the hospital elevator is not just a lift—it is an important part of the hospital’s life-support system.

But, what is a hospital elevator?

A hospital elevator is a traction or hydraulic system designed specifically for medical settings. It prioritizes stretcher and bed movement, high hygiene standards, and emergency backup functions. With its unique design, it supports smoother patient care and better hospital efficiency.

Keep reading to discover the different types of hospital elevators, their dimensions, layouts, and how to choose the best value for your facility.

What is a Hospital Elevator?

Hospital elevators, also called patient elevators, bed elevators, or medical service lifts, are made for the fast and safe transport of patients, staff, equipment, and supplies.

They look like passenger elevators but are built larger, stronger, and cleaner, often using stainless steel cabins, antibacterial coatings, rounded corners, and dust‑resistant paneling to meet hygiene demands. These materials and designs help reduce infection risk, allow easy cleaning, and withstand years of heavy daily use. As a result, these elevators shorten the time it takes to move patients and make hospital access smoother for everyone. Other names you may hear include stretcher elevators, ward elevators, and medical lifts.

What Are the Key Features of Hospital Elevators?

Hospital elevators are built to handle heavy use while still meeting strict safety and hygiene standards. They provide spacious cabins that can easily fit stretchers, wheelchairs, or even a full hospital bed, and the ride is engineered to be smooth and quiet so patients are not disturbed. Interiors are typically finished with stainless steel panels, antibacterial coatings, rounded corners, and sealed joints to make cleaning easier and reduce infection risks. Unique door systems—whether single-slide, center-opening, or folding—allow wider clear openings while saving shaft space and supporting infection control. To keep patients safe during outages, hospital elevators come with ARD auto‑rescue systems and can connect to UPS backups for continuous operation. Leveling precision is critical—often within ±5–10 mm—so stretchers can roll in and out without bumps or delays. Together, these features ensure compliance with international standards such as EN81‑72 and ADA while also delivering reliable, patient‑focused performance.

What Types of Hospital Elevators Are There?

The most common hospital elevator types are bed elevators and passenger elevators. Service elevators and cargo elevators come next, while other forms are used less often.

Passenger Elevators

Passenger elevators are the most common type found in hospitals, carrying doctors, nurses, visitors, and ambulatory patients between floors. These elevators are designed with high‑duty traction systems, quick response controls, and durable cabin finishes to handle continuous traffic throughout the day. They are often located in main lobbies or public corridors, where reliable service and smooth traffic flow are critical to hospital operations. In many cases, passenger elevators in hospitals also feature touchless call systems and enhanced hygiene measures to keep people moving safely and efficiently.

Stretcher Elevators

Stretcher elevators are designed specifically to carry stretchers and wheelchairs, with cabins long enough to fit standard gurneys and turning space for staff to maneuver. Unlike passenger elevators, which may be too narrow, stretcher elevators feature door widths of 1.4 to 1.6 meters and often use center‑opening or folding door systems to speed up entry and exit. This design reduces the risk of delays in emergencies and allows smooth transfer without awkward angles or tight turns, making them essential in emergency wards and intensive care areas.

Bed or Ward Elevators

Bed or ward elevators are designed with wider cabins to accommodate full hospital beds together with medical staff. The process of moving a bed begins with a spacious cabin geometry that provides sufficient depth and turning radius. To complete the function, these elevators often use center‑opening or folding doors, which maximize the clear entry width and reduce transfer time. This configuration allows beds to pass smoothly through the doorway and ensures that emergency teams can act quickly without spatial constraints.

Cargo elevator

Cargo elevators are a specialized category designed to move hospital equipment, laundry, and bulk supplies. These elevators are essential for ensuring that logistics flow does not interrupt patient care. Built with reinforced cabin walls, non-slip stainless steel floors, and protective bump rails, they can withstand the impact of carts, trolleys, and heavy medical machinery. Their load capacities are higher than passenger or stretcher elevators, and the interiors are designed for easy cleaning and long-term durability under constant use.

Service Elevators

Service elevators are a hybrid solution often found in smaller hospitals, where a single lift is expected to carry both people and light cargo. By combining functions, these elevators save space and reduce construction costs. They are usually equipped with medium-duty traction systems, durable yet simple finishes, and flexible door arrangements to balance passenger comfort with logistical needs.

What Are the Standard Dimensions of Hospital Elevators?

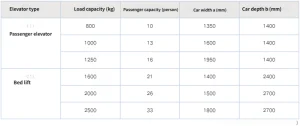

Hospital elevators often follow certain size standards, such as cabins wide and deep enough for gurneys and beds to move in and out without delay.

Here are the reference size standards for different types of hospital elevators.

These numbers should be treated only as reference values, not fixed rules, since final dimensions can vary with hospital layout, patient flow, and building codes:

- Stretcher elevator: Cabin about 1600mm × 2400mm, with a 1600mm door width.

- Bed elevator: Cabin width 1400–1600mm, depth 2400–2800mm.

- Passenger elevator: Cabin width around 1100–1400mm, depth 2100–2300mm, door width about 900–1100mm.

- Cargo elevator: Cabin width 2000–2500mm, depth 2700–3500mm, with higher load capacity up to 3000–5000kg.

- Service elevator: Medium-sized cabins, typically 1200–1600mm wide and 2200–2500mm deep, designed for both passengers and light goods.

- Load capacity: Typically 1600–2000kg for stretcher and bed elevators, higher for cargo models.

Location and Layout of Hospital Elevators

The placement of elevators inside a hospital directly affects patient care, safety, and efficiency. Crowded elevator lobbies not only slow down hospital work but also increase the risk of disease spread. Because hospitals serve doctors, patients, visitors, caregivers, and also handle both clean and contaminated items, elevator layout must follow the purpose of each lift.

Passenger Elevators

When planning elevators that carry people, three points are critical. First, designers must connect the elevator lobby smoothly with the main entrance and traffic core, so patients can find elevators quickly without confusion or long detours. Second, clear and accurate wayfinding signs in both lobbies and elevator halls are essential to guide people rapidly to their destinations. Third, elevators serving operating rooms, ICUs, and staff-only areas should be separated from public use for better management and infection control. Escalators are also becoming more common in large hospitals to share passenger flow.

Goods Elevators

Elevators for goods must also follow clear rules. Dirty‑goods elevators should be close to soiled utility rooms and temporary waste storage, with exits near outer walls or driveways for easy transfer. Elevators for incoming supplies should link directly to loading bays and storage areas. Drug elevators should connect pharmacies directly with wards and nurse stations, while small service lifts should link the central supply with operating theaters or kitchens with dining halls.

Bed Elevator Layout

Bed elevators in medical buildings mainly handle patient transport, especially for those who must stay on a hospital bed. Their lobbies and halls should be designed with extra space in crowded zones, making it easier for beds and medical staff to move quickly. In some hospitals, extra‑wide bed elevators are installed to carry two beds at once. Building design standards also recommend limiting the number of elevators placed side by side in a lobby, with practical limits set at four in a row or eight in a facing layout. This planning helps keep patient circulation safe and orderly.

How Much Does a Hospital Elevator Cost?

Hospital elevator prices vary depending on the type, size, and features. Here’s a quick overview:

| Hospital Elevator Category | Starting Price | Typical Features |

|---|---|---|

| Passenger Elevators | From $50,000 | Standard cabins, basic finishes, reliable daily transport |

| Bed/Stretcher Elevators | From $80,000 | Larger cabins, wide door openings, bed and stretcher support |

| Service Elevators | From $60,000 | Dual use for people and light goods, medium-duty systems |

| Cargo Elevators | From $100,000 | High load capacity, reinforced walls, durable finishes |

Prices may vary based on cabin size, load capacity, door type, safety add-ons, and installation complexity.

Factors Influencing Hospital Elevator Prices

You may wonder why hospital elevators cost more compared to standard passenger lifts. Several factors influence their price, and it is important to consider them before making a decision.

Material Quality

Hospital elevators use heavy-duty traction systems, stainless steel cabins, antibacterial coatings, and reinforced doors. These materials increase durability, hygiene, and long-term reliability, but they also raise the cost.

Cabin Size and Capacity

Larger cabins designed to carry stretchers, beds, or heavy medical equipment require more space and stronger construction. Higher load capacities, such as 2000 kg or more, also increase the overall price.

Door Systems

Advanced door types—center-opening, telescopic, or folding doors—provide wider openings and faster operation but add to both equipment and installation costs.

Safety and Redundancy Features

Features such as ARD auto-rescue, UPS backup integration, fire-rated doors, and advanced sensor systems ensure compliance with hospital safety codes. These additions improve patient safety but raise investment.

Customization and Standards

Custom cabin layouts, regional compliance with ADA or EN81, and tailored shaft designs all affect cost. Hospitals often pay more to achieve layouts that fit unique building constraints.

Long-Term Value

Initial cost is only part of the equation. Energy-efficient machine-room-less (MRL) elevators, like those from BDFUJI, reduce operating expenses over time while ensuring compliance and reliability.

Choosing the Right Hospital Elevator

If your hospital mainly needs to move patients on beds between emergency rooms and operating theaters, a bed elevator with wide doors and high load capacity is the most suitable choice. For daily passenger flow such as staff, visitors, and ambulatory patients, passenger elevators provide reliable service at lower cost. Smaller hospitals may save space with service elevators, while large facilities often invest in cargo elevators to handle laundry, equipment, and supplies.

Now that we have looked at the factors that influence price, it is important to match your choice to the hospital’s needs. The type, size, and layout of an elevator can transform daily operations, improving both patient care and efficiency. With BDFUJI’s worldwide experience in designing and manufacturing hospital elevators, you can select a solution that is safe, reliable, and cost‑effective for your facility.

FAQ

Are hospital elevators single-door or double-door?

Hospital elevators are usually single-door. This design saves shaft space, while folding doors can provide a wider opening without needing a bigger shaft. In terms of infection control, single-direction doors achieve better sealing and help reduce contamination risks.

What is the difference between stretcher and bed elevators?

Stretcher elevators are smaller, designed only for stretchers. Bed elevators are larger and can transport entire hospital beds with staff.

How many hospital elevators does a hospital need?

one stretcher elevator per 100 hospital beds, adjusted based on building layout and patient flow.

Do hospital elevators need backup power?

Yes. Backup power is mandatory to ensure patient safety during power failures.

What is the weight capacity of a hospital elevator?

Most hospital elevators are built to support between 1600 and 2000 kg, which covers the combined weight of a bed, patient, and staff, depending on the needs of the hospital.