As modern buildings focus more on openness and style, many now use glass elevators. Unlike old closed elevators, these clear lifts not only move people but also make the place look nicer.

As glass elevators become common, many people wonder: What is a glass elevator? How does it work? What kinds are there? What about size, cost, good and bad points, and is it right for a project? This article explores all of these aspects in detail, helping you better understand and evaluate glass elevators for your building.

What is a Glass Elevator?

A glass elevator is a type of lift where at least one side of the shaft or cabin wall is made of transparent glass. This lets passengers see the outside view while moving between floors. Traditional elevators are closed with metal or opaque walls, but glass elevators mix design with function, making the ride part of the experience.

Glass elevator is not only about moving up and down but also about giving an added dimension—sight. Because of this, glass elevators are often chosen for luxury residences, hotels, malls, and towers. They are both a way to travel and a design feature.

Key Features of Glass Elevators

Glass elevators have several important characteristics that make them different from traditional.

- Automatic and safe control: They are operated with advanced systems that keep rides smooth and safe.

- Architectural aesthetics: Transparent walls add style and improve the look of the building.

- Visual openness: Passengers enjoy wide views and feel less confined.

- Compact structure: Supported by steel frames, they use less space.

- Seamless integration: Easy to match with modern architecture and interior design.

- Wide applications: Common in shopping malls, hotels, offices, and upscale homes.

Structure and Working Principle of Glass Elevators

What are the Components of a Glass Elevator?

Glass elevators are made up of different parts that work together as one system. These components are:

- Pit: This is the base of the shaft. It holds the buffer seats, guide rail bases, and drainage system.

- Shaft: Built from a steel frame and transparent panels, it also includes the doors and support equipment.

- Cabin: The car where people ride, made of a cabin frame, glass walls, floor base, ceiling, control panel, and doors.

- Machine room/equipment layer: Houses the traction motor, sheaves, support beams, and the speed governor.

- Other parts: Includes the suspension system, counterweight, safety devices, guide rails, buffers, limit switches, and electrical systems.

How Ddoes a Glass Elevator Work?

A glass elevator usually works with a traction system. This system uses steel ropes that pass over a traction sheave. One end of the rope is fixed to the cabin, and the other is fixed to the counterweight. When the electric motor turns the sheave, the cabin moves smoothly up or down to the selected floor.

The main steps in the process are as follows:

- Traction motor activation: The motor starts and provides power for movement.

- Rope and sheave movement: The steel ropes slide over the sheave, creating motion.

- Counterweight balance: The counterweight moves in the opposite direction to balance the load and save energy.

- Cabin travel: The cabin rises or descends smoothly to the desired level.

- Braking system: Safety brakes ensure the elevator stops gently and securely at each floor.

What are The Different Types of Glass Elevators?

Glass elevators can be designed in several ways, and the differences are most clear when we look at the shaft structure and the cabin shape. Each option has its own build and set of features.

By Shaft Structure

Open Steel-structure Shaft

Open steel-structure shafts are built with a visible steel frame and glass panels that leave much of the structure open. This openness provides riders with nearly unobstructed views and makes the elevator a striking feature of the building. Because the framework is lighter and less covered, it often requires fewer materials. The trade-off is that it offers less protection from wind, rain, and other weather conditions.

Enclosed Steel-structure Shaft

Enclosed steel-structure shafts use a complete frame of steel columns and beams, with all sides sealed by glass or similar panels. This design creates a closed environment that shields both passengers and machinery from outdoor elements.

By Glass Elevator Shape

Semi-circular Glass Elevator

A semi-circular glass elevator has a rounded front made of curved glass panels. The design gives passengers wide-angle, panoramic views and creates a smooth, modern appearance. Building this type requires specially bent glass and a reinforced frame to hold the curve securely.

Cut-corner Glass Elevator

A cut-corner glass elevator is built with angled or chamfered corners, giving it a polygonal look instead of a strict rectangle. This reduces sharp edges inside, makes the ride feel more spacious, and adds a stylish, contemporary look that fits well with modern architectural layouts.

Square Glass Elevator

A square glass elevator is constructed with four straight walls at right angles. This is the simplest and most common design, easy to manufacture and install. Its regular geometry makes it versatile for both residential and commercial use, and it fits standard shaft dimensions without major adjustments.

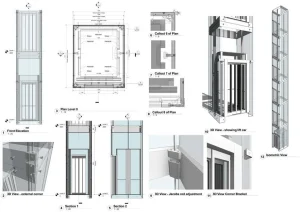

What are The Steps to Install a Glass Elevator?

The process of installing a glass elevator spans several linked stages—from the first site assessment to final commissioning and handover.

Each stage protects structural integrity, passenger safety, ride quality, and code compliance.

- Evaluate Site & Technical Requirements — Check pit depth, headroom/overhead, shaft size, structural capacity, power supply, and local codes.

- Fabricate & Build the Shaft Structure — Erect the steel frame, set anchor plates/embeds, apply corrosion protection, and install/ seal glazing.

- Install the Guide‑Rail System — Set base plates, plumb and align rails, and fasten brackets to the structure.

- Install Traction Machine & Sheaves — Place machine beams, traction motor, overspeed governor, and sheaves; verify alignment.

- Fit Doors & Frames — Install sills, headers, frames, landing doors, interlocks, and make fine adjustments.

- Install Counterweight & Glass Elevator Car — Assemble car frame/platform/door operator/glass panels; mount counterweight and guide shoes.

- Rig & Tension Ropes (or Belts) — Cut to length, reeve over sheaves, make rope ends, equalize tension; add compensation if required.

- Wire the Electrical & Control System — Mount controller, run traveling cable, connect safety circuits, sensors, and limit switches.

- Test, Commission & Handover — Perform no‑load/load tests, governor trip, buffer test, door safety checks, leveling/ride tuning, and documentation.

Step 1: Evaluate Site & Technical Requirements

Before installation, confirm that the building can safely accept a glass elevator. Verify pit depth (for buffers and clearance), headroom/overhead (for car top clearance and equipment), and shaft size (clear widths/depths).

Check structural capacity of floors/walls for steel frame anchors and dynamic loads. Ensure power supply (e.g., 3‑phase service, grounding, emergency power where required) and plan drainage in the pit.

Review codes and standards (e.g., ASME A17.1/EN 81/GB) and site logistics (rigging paths, crane access). For outdoor units, assess wind, temperature, humidity, and UV exposure to select suitable materials and sealing systems.

Step 2: Fabricate & Build the Shaft Structure

Lay out control lines, set anchor/embedded plates, and erect steel columns and beams (bolted/welded).

Check plumbness and squareness within tolerance; tighten to specified torque. Apply corrosion protection (galvanized or primed/painted) and install glazing with gaskets and sealants while preserving required clearances.

Note: this work is typically performed by a qualified steel/glazing contractor and coordinated with the elevator installer.

Step 3: Install the Guide‑Rail System

Install rail base plates in the pit, then stack rails with fishplates, shimming as needed to achieve plumb and straightness. Fix rail brackets to the shaft at the specified spacing. Proper rail alignment is critical for ride comfort and noise control.

Step 4: Install Traction Machine & Sheaves

Set machine beams and anti‑vibration pads; place the traction motor and align the traction/deflecting sheaves. Mount the overspeed governor (and the governor tension device in the pit). Guard moving parts according to code.

Step 5: Fit Doors & Frames

Install sills, headers, and frames at each landing, then hang landing doors. Set clearances, adjust interlocks, and verify that door zones, locks, and indicators operate correctly.

Step 6: Install Counterweight & Glass Elevator Car

Assemble the counterweight frame and filler blocks; install guide shoes/rollers. Build the car sling and platform, mount the door operator, and fix tempered/laminated glass panels with certified clamps or frames. Balance the system according to the specified car and counterweight masses.

Step 7: Rig & Tension Ropes (or Belts)

Measure and cut ropes to length, reeve them over the sheaves, and make rope ends (e.g., wedge sockets/terminals). Equalize rope tension and, if required, install compensation ropes/chains to stabilize ride quality at higher travel distances.

Step 8: Wire the Electrical & Control System

Mount the controller, route the traveling cable, and connect the safety circuits (limits, governors, door contacts), sensors, encoders, and communication lines. Verify insulation, continuity, and proper labeling.

Step 9: Test, Commission & Handover

Power up and conduct no‑load runs, then perform rated and 125% load tests. Test governor overspeed, brake, buffers, and door protection devices. Tune leveling, acceleration, and deceleration for ride comfort. Complete documentation, perform final inspections, and train building staff on operation and basic maintenance.

Because installation requires specialized expertise, it must be performed by certified technicians. BDFUJI provides end‑to‑end guidance and on‑site technical support for glass elevator installations.

Glass elevator dimensions

The dimensions of a glass elevator are not fixed—they change with building type, usage, and design standards. To understand them clearly, it helps to look at the main elements:

- Cabin size – The inside space where passengers stand. In homes, a common size is about 1,000 mm × 1,200 mm, which fits 2–3 people. In malls or hotels, the cabin may be much larger, sometimes more than 2,000 mm deep, to carry groups of people at once.

- Shaft width – The total space needed to install the elevator shaft. This usually ranges from 1.5 to 2.5 meters, but high‑capacity glass elevators may need even wider shafts for structural support.

- Door width – The opening passengers use to enter and exit. Most are between 800 and 1,000 mm, but public buildings may require wider doors to meet accessibility codes.

- Overhead and pit depth – Overhead space (above the top floor) and pit depth (below the ground floor) are also critical. Typical pit depths range from 1–1.5 m, while overhead clearance can be 3.5–4.5 m or more depending on speed and capacity.

Here’s how they compare in a simple view:

| Factor | Residential Glass Elevator | Commercial Glass Elevator |

|---|---|---|

| Cabin size | ~1,000 × 1,200 mm (2–3 persons) | 1,600–2,000 mm+ (6–15 persons) |

| Shaft width | 1.5–1.8 m | 2.0–2.5 m or more |

| Door width | 800–900 mm | 900–1,200 mm |

| Pit depth | 1–1.2 m | 1.2–1.5 m+ |

| Overhead clearance | 3.2–3.8 m | 4.0–4.5 m+ |

For unique projects, BDFUJI offers customized glass elevators that adapt to specific building layouts, safety codes, and space constraints.

How Much Does a Glass Elevator Cost?

At first glance, glass elevators may appear to be a premium choice, but their long‑term value often justifies the investment—especially in projects that prioritize style, openness, and rider experience. While upfront costs can be higher than those of standard elevators, glass elevators add architectural appeal, increase property value, and provide unique functionality.

Several factors shape the overall cost:

- Size and load capacity – Larger cars with higher weight ratings require stronger structures and more powerful motors.

- Number of floors served – Each additional stop adds landing doors, controls, and labor.

- Cabin design and materials – Curved glass, stainless steel finishes, or custom lighting raise costs compared to basic square cars.

- Installation complexity – Outdoor shafts, retrofits into existing buildings, or scenic open structures demand more time and resources.

Typical price ranges are:

- Residential glass elevators: $25,000–$60,000 including installation. These serve 2–3 floors with modest cabin sizes.

- Commercial glass elevators: $80,000–$200,000+ depending on travel height, capacity, and customization.

Beyond the purchase price, there are ongoing costs:

- Electricity – Comparable to running a refrigerator or washing machine, usually a few dollars per month for homes.

- Maintenance – Annual inspections, cleaning, and adjustments typically range from $2,500–$5,000 depending on usage and region.

Here’s a simple comparison:

| Factor | Residential Glass Elevator | Commercial Glass Elevator |

| Price range | $25,000–$60,000 | $80,000–$200,000+ |

| Floors served | 2–3 | 4+ |

| Capacity | 250–450 kg | 1,000 kg or more |

| Design options | Basic square or semi‑circular | Wide range with custom glazing/forms |

| Annual maintenance | $2,500–$4,000 | $3,500–$5,000 |

What are The Advantages of Glass Elevators?

Glass elevators provide several clear advantages that make them attractive for modern buildings. You can expect design value, passenger comfort, and architectural impact all in one system. Here are the main advantages to consider:

- Enhance building aesthetics and value – Transparent walls add elegance and improve property appeal, often increasing market value.

- Provide a panoramic and enjoyable ride experience – Riders can view surroundings as they travel, turning a simple lift into an experience.

- Create an open and welcoming atmosphere – The visual openness makes buildings feel brighter and more spacious.

- Fit premium environments – Glass elevators work especially well in luxury spaces, malls, hotels, and tourist attractions where style and experience are important.

What are The Disadvantages of Glass Elevators?

While glass elevators have clear benefits, they also present some challenges that must be considered before choosing them for a project. Here are the main disadvantages:

- Higher upfront and installation costs – The use of glass panels, custom steel framing, and architectural finishes raises the initial price compared to standard elevators.

- Require specialized cleaning and maintenance – Glass walls show dust, smudges, and fingerprints easily, and they require special cleaning solutions and regular upkeep to remain visually appealing.

- Construction is more complex – The combination of structural steel, glazing, and mechanical systems means longer installation times and the need for skilled labor.

- Not ideal for small or low-budget projects – Glass elevators require more shaft space and higher budgets, making them less practical for small buildings or cost-sensitive developments.

How to Decide if a Glass Elevator is Right for Your Building?

Determining whether a glass elevator fits your project is about weighing benefits against constraints. Even small differences in budget or space can change the outcome.

- Design value – Glass elevators adFor flexible solutions, BDFUJI’s glass elevators are available in multiple designs (semi-circular, square, or cut-corner), making it easier to match your architectural needs.d modern style and improve the look of a building.

- Rider experience – They provide open views and make the ride more enjoyable.

- Property impact – By enhancing both function and image, they can raise property value.

- Budget and space check – They may not be practical if the project has tight cost limits or restricted shaft space.

In short, if aesthetics, experience, and prestige are top goals, a glass elevator is an excellent choice. But if budget or layout is limited, a standard elevator may be the better option.

Conclusion

A glass elevator is more than just a way to move between floors—it’s an architectural feature that combines engineering, safety, and design. By understanding its definition, structure, types, installation, costs, and pros and cons, you can decide whether it’s the right fit for your building.

If you’re planning a new project, partnering with an experienced manufacturer like BDFUJI ensures you get both technical excellence and aesthetic integration

FAQs

1. Can glass elevators be installed in any type of building?

Yes. Glass elevators can be used in residential, commercial, and even outdoor settings as long as structural and safety requirements are met. They are common in malls, hotels, and luxury homes.

2. What is the difference between a glass elevator and a standard elevator?

A glass elevator has transparent walls for visibility, while standard elevators are fully enclosed.

3. How much weight can a glass elevator carry?

It depends on the model—residential versions usually carry 250–450 kg, while commercial models handle 1,000 kg or more.

4. How often does a glass elevator need maintenance?

Regular maintenance is needed every 6–12 months, depending on usage and local regulations.

5. How long does installation glass elevatortake?

Most projects take between 4 and 12 weeks, depending on the building type, number of stops, and installation complexity.