Freight elevators are very important for moving heavy items in places like warehouses and factories. But with so many options, how do you know which size and type to choose? Whether you are replacing an old elevator or installing a new one, it’s important to understand what makes each elevator different. In this guide, we will explain the different sizes and features of freight elevators.

Did You Know? A standard Class A freight elevator usually has a platform size of 10 feet by 10 feet, giving it plenty of space to carry large items like pallets and heavy equipment.

Why Freight Elevator Size is Important

The size of a freight elevator is more than just a number; it affects many important aspects of your building’s daily operations. The right size ensures that heavy items, such as equipment, pallets, and furniture, can be safely and easily moved between floors. It also impacts:

-

Efficiency: A properly sized elevator makes transportation faster and smoother, saving time and effort.

-

Safety: If the elevator is too small, there may be risks of overloading, which can lead to accidents.

-

Cost-effectiveness: Choosing the right size helps avoid unnecessary costs related to installation, maintenance, and energy usage.

-

Space planning: A well-sized elevator ensures that the elevator fits well within the available space, without wasting valuable room.

Understanding the right size for your freight elevator ensures it works efficiently and safely for your building’s needs.

Typical Freight Elevator Dimensions

Freight Elevator Load Classifications

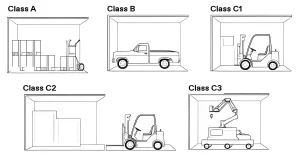

Before looking at the size of freight elevators, let’s first understand the load classifications. These classifications are based on the largest weight a freight elevator can carry per square foot. This helps determine what type of items the elevator can transport and how heavy they can be. Here are the load classifications:

-

Class A (General Freight): This type of elevator can carry 50 pounds per square foot. It is designed for transporting regular goods like machines, equipment, and other medium-weight items.

-

Class B (Vehicle Loading): This type can carry 30 pounds per square foot and is mainly used for transporting vehicles, such as cars or other heavy items.

-

Class C-1 (Industrial Truck Loading – Trucks Transported by Elevator): This type can carry 50 pounds per square foot but must handle the weight of the truck, including the truck’s weight. It is used for environments where trucks need to be moved using the elevator.

-

Class C-2 (Industrial Truck Loading – Trucks Used for Loading/Unloading Only): This type is used for elevators with a capacity of 20,000 pounds or less. The largest weight should match the weight of the truck, and the loading weight should not exceed 150% of the rated capacity. This elevator is ideal for unloading trucks but not for transporting them.

-

Class C-3 (Other High-Density Loads Without Trucks): This type can carry 5 pounds per square foot but must handle specific load requirements without using trucks. It’s best for moving small equipment or lighter items.

These load classifications ensure that freight elevators are chosen based on their specific transportation needs, providing safety and efficiency for different types of loads.

Standard Freight Elevator Dimensions and Load Capacity

Freight elevator dimensions and load capacities vary depending on the specific needs of your building. Below are typical sizes, features, and load classifications for different freight elevators. You can choose the right elevator based on your building’s requirements:

| Load Capacity | Platform Size | Cabin Height | Door Width | Door Height |

|---|---|---|---|---|

| 4000 lbs | 7′-0″ x 8′-0″ | 8′-0″ | 6′-8″ x 7′-7″ | 6′-8″ x 8′-0″ |

| 4000 lbs | 7′-0″ x 8′-0″ | 8′-0″ | 6′-8″ x 7′-6″ | 6′-8″ x 8′-0″ |

| 5000 lbs | 8′-0″ x 9′-0″ | 8′-0″ | 7′-8″ x 8′-7″ | 7′-8″ x 8′-0″ |

| 5000 lbs | 8′-0″ x 9′-0″ | 8′-0″ | 7′-8″ x 8′-6″ | 7′-8″ x 8′-0″ |

| 6000 lbs | 10′-4″ x 10′-0″ | 8′-0″ | 10′-0″ x 9′-7″ | 10′-0″ x 8′-0″ |

| 6000 lbs | 10′-4″ x 10′-0″ | 8′-0″ | 10′-0″ x 9′-6″ | 10′-0″ x 8′-0″ |

| 8000 lbs | 10′-4″ x 12′-0″ | 8′-0″ | 10′-0″ x 11′-7″ | 10′-0″ x 8′-0″ |

| 8000 lbs | 10′-4″ x 12′-0″ | 8′-0″ | 10′-0″ x 11′-6″ | 10′-0″ x 8′-0″ |

| 10000 lbs | 10′-4″ x 14′-0″ | 8′-0″ | 10′-0″ x 13′-7″ | 10′-0″ x 8′-0″ |

| 10000 lbs | 10′-4″ x 14′-0″ | 8′-0″ | 10′-0″ x 13′-6″ | 10′-0″ x 8′-0″ |

| 12000 lbs | 12′-4″ x 12′-0″ | 8′-0″ | 12′-0″ x 11′-7″ | 12′-0″ x 8′-0″ |

| 12000 lbs | 12′-4″ x 12′-0″ | 8′-0″ | 12′-0″ x 11′-6″ | 12′-0″ x 8′-0″ |

| 15000 lbs | 12′-4″ x 16′-0″ | 8′-0″ | 12′-0″ x 15′-7″ | 12′-0″ x 8′-0″ |

| 15000 lbs | 12′-4″ x 16′-0″ | 8′-0″ | 12′-0″ x 15′-6″ | 12′-0″ x 8′-0″ |

| 20000 lbs | 12′-4″ x 20′-0″ | 8′-0″ | 12′-0″ x 19′-7″ | 12′-0″ x 8′-0″ |

| 20000 lbs | 12′-4″ x 20′-0″ | 8′-0″ | 12′-0″ x 19′-6″ | 12′-0″ x 8′-0″ |

| 25000 lbs | 14′-4″ x 20′-0″ | 8′-0″ | 14′-0″ x 19′-7″ | 12′-0″ x 8′-0″ |

| 25000 lbs | 14′-4″ x 20′-0″ | 8′-0″ | 14′-0″ x 19′-6″ | 12′-0″ x 8′-0″ |

These sizes fit a variety of needs, from smaller freight loads to heavy-duty transport. The platform size and cabin height ensure that goods can be transported safely and efficiently between multiple floors.

Recommended reading:

Freight Elevator: What It Is, How It Works and Uses

Key Specifications to Consider

When choosing a freight elevator, it’s important to understand the key specifications that affect how well the elevator works. Here are the main things to consider:

-

Load Capacity This tells you how much weight the elevator can carry. Most freight elevators can carry anywhere from 2,000 to 6,000 lbs, but some heavy-duty models can carry even more. Make sure to choose an elevator that can handle the heaviest items you plan to move.

-

Speed Speed is important for efficiency. Most freight elevators move at speeds of 30 to 80 feet per minute. If you need to move items quickly, consider a faster model, but keep in mind that safety and smooth operation should still come first.

-

Form Height The form height is the inside height of the elevator. It determines how tall the items you transport can be. For larger items like furniture or equipment, you’ll need an elevator with a higher form height.

-

Drive System There are different drive systems, like hydraulic, traction, and machine-room-less (MRL). Each system has its own benefits. For example, hydraulic systems offer a smooth ride, while MRL systems are more energy-efficient and take up less space. Choose the system that best fits your building’s needs and space.

Space Requirements for Freight Elevator Installation

Planning ahead is key when installing a freight elevator. Here’s what you need to consider:

-

Pit and Overhead Clearance

-

Pit: Most freight elevators need a pit, usually around 8″ to 12″ deep. This pit is essential for the elevator to reach the lowest floor.

-

Overhead Clearance: You will need space above the elevator for the system to operate. This usually ranges from 8 to 10 feet, depending on the model.

-

-

Shaft Space Freight elevators need a vertical shaft to move up and down. The size of the shaft will depend on the size of the elevator, but it needs to be wide and tall enough to fit the entire system.

-

Power Supply Freight elevators need power, often a three-phase power supply. This is usually available in most commercial buildings and ensures the elevator runs smoothly and efficiently.

Customization Options for Freight Elevator Size

Modern freight elevators can be customized to fit different needs and spaces. Here are some common customization options:

-

Cabin Size: You can choose a larger or smaller cabin depending on what you need to move. This helps if you need extra space for bulky items or want a more compact design.

-

Door Width: Some freight elevators allow you to adjust the door width to make loading and unloading easier for large items like pallets or equipment.

-

Weight Capacity: You can customize the elevator’s weight limit to carry heavier loads, ensuring it fits your specific needs.

-

Speed: Some models offer faster speeds for moving goods quickly, which can be helpful in busy commercial spaces.

These customization options allow you to choose a freight elevator that works best for your space and what you need to transport.

How to Choose the Right Size Freight Elevator

Here’s a quick checklist:

-

What’s the largest weight you need to move?

-

How much space is available for the elevator?

-

How many floors will the elevator serve?

-

Do you need extra space for oversized items like pallets or equipment?

-

What’s your budget for installation and maintenance?

For many businesses, a balance of size, capacity, and efficiency is key. Choosing the right size ensures safe and easy transportation of goods. Explore different models and speak to BDFUJI to find the best fit for your needs.

Recommended reading:

Freight Elevator Costs: The Latest Price Guide

Can a Freight Elevator Be Used for Passengers?

Freight Elevator vs Passenger Elevator: What is the Difference?

Service vs. Freight Elevator: What’s the Difference?

Conclusion

Choosing the right size freight elevator is important for moving goods safely and easily. By thinking about things like the weight you need to move, the space available, and the elevator’s speed, you can find the right one for your building. You can also make changes to the elevator, like adjusting the cabin size or door width, to fit your needs. To make the best choice, talk to BDFUJI and find the right freight elevator for your space.