A freight elevator is a big lift that moves heavy things between floors. People started using them over 100 years ago, when buildings got taller and needed help moving goods. Today, freight elevators are used in many places like stores, factories, and hospitals. They make moving large items safer and easier.

What Is a Freight Elevator?

In short, freight elevators are heavy-duty lifts that carry goods between floors in buildings like warehouses, factories, and shopping centers. Freight elevators come in many sizes — from small models that carry boxes and carts to large ones that can hold pallets, machines, or even vehicles. There are six main types of freight elevators, and each one works a little differently.

Types of Freight Elevators

-

Traction freight elevators Traction freight elevators use ropes and counterweights to lift and lower heavy items. They are energy-efficient and often used in tall buildings or places with large lifting needs.

-

Hydraulic freight elevators Hydraulic freight elevators use fluid pressure to raise goods. These elevators are smooth and quiet, making them a good choice for low- to mid-rise buildings.

-

Machine-room-less (MRL) freight elevators Machine-room-less, or MRL freight elevators, keep all their parts inside the shaft. They save space and work well in buildings with limited room.

-

Material lifts Material lifts, also called vertical conveyors, move goods between floors in warehouses and factories.

-

Car elevators Car elevators are made to carry vehicles and are common in parking garages, car showrooms, and service centers.

-

Small dumbwaiters Small dumbwaiters carry light items like food or supplies and are often used in restaurants, hotels, and homes.

Freight elevators can also be grouped by how much weight they are built to carry. While exact limits may vary by manufacturer, most models follow these standard load classes.

-

Class A freight elevators Class A freight elevators are made for light-duty jobs. They can carry small goods up to 2,000 pounds and are common in stores and office buildings.

-

Class B freight elevators Class B freight elevators handle heavier items and loads up to 3,500 pounds. They are used in places like factories and warehouses.

-

Class C1 freight elevators Class C1 freight elevators are built for very heavy loads, such as machines or vehicles. They can carry between 5,000 and 10,000 pounds.

-

Class C2 freight elevators Class C2 freight elevators can handle over 10,000 pounds. These strong elevators are used for mining, construction, and other industries with extra-large equipment.

Freight elevators aren’t just big metal boxes that go up and down. Like other elevators, they follow a clear process to lift goods safely between floors. Most work by pulling or pushing the elevator car with a system of ropes, pistons, or motors. They start at the bottom and move upward smoothly, stopping at each floor as needed — just like we planned.

How Do Freight Elevators Work?

Freight elevators work a lot like passenger elevators but are built to move goods instead of people. They use strong mechanical systems, like ropes, pulleys, or hydraulic pistons, to carry heavy items between floors. These systems are designed to safely lift everything from small packages to full-size vehicles.

It takes a combination of motors, steel frames, control systems, and safety devices to move freight smoothly and reliably. The process may sound simple — go up, go down — but there’s more happening behind the scenes. Below are some of the key parts and steps that help freight elevators do their job.

Power and Lifting Systems

Freight elevators use two main lifting systems: traction and hydraulic. Traction elevators use steel ropes and counterweights to move the car. A motor turns a pulley that pulls the car up or lets it down. Hydraulic elevators push the car upward using fluid pressure in a piston. These systems are slower but good for shorter buildings.

Both systems are built to handle heavy weights and stop smoothly at each floor. Some freight elevators use gearless motors for even smoother movement.

Control Systems

Every freight elevator has a control system that tells it when to start, stop, speed up, or slow down. These systems follow commands from buttons or switches and make sure the elevator reaches the right floor.

Older elevators use relay logic, while modern ones use microprocessors and software. These controls help improve safety, save energy, and make the ride smoother.

Safety Features

Freight elevators carry heavy loads, so safety is very important. They include brakes, door locks, overload sensors, and emergency stop buttons. If the elevator is too heavy, it won’t move until some weight is removed. If the doors aren’t fully closed, the elevator won’t start.

Some elevators also have backup power, so they can reach the next floor even if the electricity goes out.

Elevator Shaft and Car Structure

Freight elevators travel up and down inside a vertical shaft. The shaft is made of concrete or steel to keep the elevator stable. The car itself is large and strong, with a flat metal floor, solid walls, and wide doors. Some even allow forklifts to drive inside.

The car may move slowly, but it’s designed for strength — not speed. Everything inside is built to last under heavy use.

Materials Freight elevator Can Carry

Freight elevators are used to move many different things. These include:

-

Pallets of goods in a warehouse

-

Tools and machines in factories

-

Furniture and supplies in hospitals or hotels

-

Even vehicles in car showrooms or parking garages

The size and weight of what they carry depends on the elevator’s load class and design.

Freight Elevator Operating Speed

Most freight elevators are slower than passenger elevators. They move between 30 and 100 feet per minute, depending on the model. A short trip between two floors may take just 10–20 seconds. But moving large goods between 10 or more floors could take over a minute.

Freight elevators are not built for speed — they are built for safety and strength.

Freight Elevator Dimensions and Weight Capacity

When planning a freight elevator, one of the key considerations is its physical size and load capacity. These factors determine what types of cargo the elevator can safely carry and how it integrates into the building structure.

Weight Capacity

Freight elevators are designed to handle much heavier loads than passenger elevators. Small freight elevators typically support 2,000–4,000 lbs (about 1–2 tons). Medium-duty models can lift between 10,000 and 20,000 lbs, while custom-built heavy-duty systems for factories may exceed 40,000 lbs. Choosing the right capacity ensures that goods can be transported without overloading the system.

Cab Dimensions

The inside space of the elevator cab varies widely depending on application. A small freight elevator might measure about 5 feet by 7 feet, while a large Class C model could be 12 feet by 14 feet or more. Cab height is also important, usually ranging between 8 and 12 feet to accommodate tall equipment or stacked pallets.

Door Sizes

Because freight elevators often need to fit forklifts or large pallets, door openings are wider than those of passenger elevators. Door widths generally start around 6 feet and can exceed 12 feet in heavy-duty designs.

Purpose of Freight Elevators

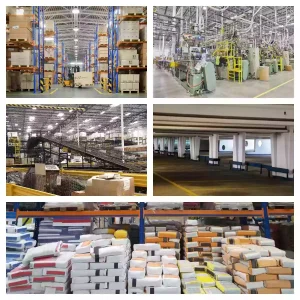

Freight elevators are used in many different fields and offer practical solutions to real-world challenges. Here are some powerful examples of how they help buildings and businesses run smoothly.

Common Uses for Freight Elevators:

-

Warehousing and Logistics

-

Manufacturing and Industry

-

Automotive Showrooms and Garages

-

Construction Sites

-

Hotels, Restaurants, and Homes

-

Hospitals and Public Buildings

Warehousing and Logistics

In warehouses and shipping centers, freight elevators help move pallets, crates, and large packages between floors. Workers use them to load trucks, restock shelves, and manage storage without using ramps or forklifts.

Manufacturing and Industry

Factories use freight elevators to lift machines, tools, and heavy materials. These elevators make it easier to move equipment from one floor to another and reduce the risk of injury for workers.

Automotive Showrooms and Garages

Car elevators are designed to carry full-size vehicles. They are used in showrooms, repair shops, and parking garages to move cars where ramps won’t fit. These lifts save space and make vehicle storage easier.

Construction Sites

On building sites, outdoor freight elevators move materials like cement, wood, and tools up unfinished buildings. They’re built to handle bad weather and rough conditions, making them key to safe construction.

Hotels, Restaurants, and Homes

Small freight elevators, like dumbwaiters, carry food, dishes, laundry, or groceries between floors. In homes or apartments, they help residents avoid carrying heavy loads up the stairs.

Hospitals and Public Buildings

Hospitals use freight elevators to move beds, medical machines, and supply carts. These elevators are wide enough for stretchers and help staff work faster without blocking passenger elevators.

Freight elevators may be hidden behind doors, but they keep businesses, buildings, and cities moving every day.

How to Build a Freight Elevator?

Installing a freight elevator takes several steps:

-

Site Evaluation: Measure space, check floors, ceiling height, and power supply.

-

Design Plan: Choose size, weight limit, and type (hydraulic or traction).

-

Permit and Code Check: Make sure local laws and fire codes allow it.

-

Construction: Build the hoistway (shaft), install the elevator car, doors, and machine system.

-

Testing: Inspect and test safety systems before use.

How Long Does The Freight Elevator Installation Take?

Installing a freight elevator usually takes several weeks to a few months, depending on the size and type. A small dumbwaiter might take just a few days, while a large multi-floor freight elevator could take 8–12 weeks to finish.

You can’t build a freight elevator overnight, but with careful planning and the right team, you can turn it into one of the most useful parts of a building.It’s important to hire a trained elevator company to follow U.S. safety rules, like ASME A17.1. This makes sure the elevator is safe, works well, and meets the law.

Freight Elevator vs Passenger Elevator: What are The Differences?

Freight elevators and passenger elevators both move between floors, but they operate very differently in terms of purpose, design, and performance. Freight elevators are engineered to carry goods and equipment, while passenger elevators are made for moving people.

Traditional passenger elevators focus on comfort, aesthetics, and speed, often with capacities of 1,000–3,500 lbs and stylish interiors. By contrast, freight elevators use reinforced steel floors, wide doors, and rugged frames to manage loads from 2,000 lbs to over 20,000 lbs. Their slower speed ensures safety during heavy transport, while their higher cost reflects heavy-duty construction and long-term durability.

The table below highlights the main differences:

| Factor | Freight Elevator | Passenger Elevator |

|---|---|---|

| Purpose | Transport goods, equipment, or vehicles | Transport people |

| Design | Rugged steel floors, reinforced walls, wide doors | Comfort, lighting, aesthetic finishes |

| Speed | Slower, prioritizes safe heavy lifting | Faster, prioritizes quick movement |

| Capacity | 2,000–20,000+ lbs | 1,000–3,500 lbs |

| Cost | Higher due to heavy-duty build | Lower, standard construction |

Conclusion

A freight elevator is more than just a lift; it’s a game-changing solution for industries that need to move heavy goods with safety, reliability, and efficiency. From small freight elevators in hospitals and restaurants to massive freight lift elevators in large-scale factories, these systems are engineered to handle the heaviest and most demanding jobs without compromise.

But as you know, success depends as much on the partner you choose as on the equipment itself. You need a manufacturer that understands your challenges and delivers consistent quality—every single time.

At BDFUJI, we do exactly that. Our freight elevator solutions are built for both strength and customization. With international certifications and decades of expertise, we provide safe, reliable, and adaptable systems for residential, commercial, and industrial projects worldwide. Whether you’re comparing freight elevator vs passenger elevator or planning a new installation, we help you hit your goals, stay on schedule, and control costs.

Freight Elevator FAQ

Are freight elevators safe?

Yes, when properly installed and maintained. They include safety brakes, emergency stops, and alarms. Most U.S. states require regular inspections by law.

Can passengers ride in freight elevators?

Usually not. Most freight elevators are not built for passengers. Unless certified for dual use, carrying people may be unsafe or illegal.

What is the maximum weight a freight elevator can carry?

Standard freight elevators carry between 2,000 and 6,000 lbs. Heavy-duty models can transport up to 30,000 lbs or more. Always check the elevator’s rated load plate.

How do I choose the right freight elevator?

Consider these factors:

- Weight and size of the items

- Number of floors served

- Available space and power supply

- Budget

- Local building codes

Consult an elevator specialist to select the right model for your needs.