Escalator prices can vary widely. Factors such as brand, type, lifting height, dimensions, and labor costs all contribute to the total price.

On average, the cost of an escalator is expected to range between $60,000 and $70,000, though custom-built options may cost more.

What Is an Escalator?

Before diving into pricing, let’s take a quick look at what an escalator actually is.

An escalator is a machine that helps people move between floors. You can often see it in shopping malls, subway stations, and airports. It has moving steps that carry people up or down. People just need to step on and stand still. The escalator does the rest.

For example:

When you walk into a large shopping center, you’ll often see a set of continuously moving stairs—that’s an escalator. Its steps keep moving, allowing you to stand and be carried up or down effortlessly.

Basic Structure of an Escalator

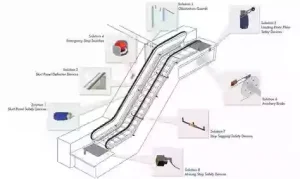

An escalator consists of several key parts,including:

- motor

- drive chain

- step treads

- support frame

- safety system

The motor drives the chain, which moves the steps along a fixed track. As a result, passengers can step on and be smoothly transported between floors.

How It Differs from an Elevator

Unlike elevators, escalators don’t stop to let people in or out. They work well for moving people short distances, especially in busy places like subways or airports. Their width, angle, and speed can be customized based on the installation environment. The standard step width is 1000 mm, but other sizes are available.

Modern escalators often have safety tools like emergency stop buttons, step jam sensors, and load monitors. They may also use smart controls and energy-saving modes to cut power use and lower running costs.

If you’re looking for a convenient, safe, and energy-efficient way to improve traffic flow within a building, an escalator is a great option.

Types of Escalators

Beyond the cost of escalators, it’s important to understand the different types available. Each type is designed for specific buildings and use cases, and prices vary accordingly.

1. Parallel Escalators

Parallel escalators are the most common type. They usually operate in pairs—one going up and the other going down. Their simple and compact design fits well in busy places like malls, subways, and airports.

2. Many Parallel Escalators

When foot traffic is heavy, a single pair of parallel escalators may not be enough. In these cases, installing many parallel escalators can significantly improve passenger flow. This setup is often used in central areas of malls or transit stations, creating a multi-directional transport network.

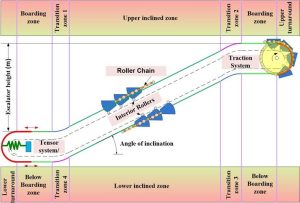

3. Inclined (Stepped) Escalators

Stepped escalators have a distinct stair-like design with a greater vertical lift than flat escalators. They are commonly used in buildings with high ceilings or steeper inclines. These escalators have raised steps, so passengers stand upright as they move, like climbing stairs with electric help.

4. Spiral Escalators

Spiral escalators use a curved layout that winds upward or downward. This unique design allows for creative space use. These escalators are often used in high-end malls or exhibition halls where both use and appearance matter.

5. Moving Walkways

Moving walkways, also known as travelators or flat escalators, help people move across long, flat spaces in airports and exhibition halls. They have no steps, so passengers can walk easily or push carts, making long trips more comfortable.

There are many types of escalators, each with unique features. Choosing the right one depends on several factors, such as usage environment, building layout, foot traffic, and budget. You can contact BDFUJI directly for a comprehensive assessment of your site’s needs. We’ll help you choose the most suitable escalator type to improve spatial efficiency and passenger flow.

For more details, see: “Escalator Types: The Complete Guide for 2025.”

How Much Does It Cost to Install an Escalator?

The cost of installing an escalator depends on its size, location, features, and how complex the site is.

Price Range for Different Escalator Types

- In general, the price of a standard escalator ranges from $50,000 to $325,000. Specifically:

- Standard width (1000mm) escalators typically cost between $120,000 and $150,000.

- Wider models (e.g., 1400mm) are more expensive, usually $180,000 to $220,000.

- Custom or heavy-duty escalators designed for large public transport systems can cost over $300,000.

These prices usually include the equipment and basic shipping, but not labor or building costs.

Indoor vs. Outdoor Escalator Costs

Outdoor escalators are more expensive due to the following:

- Use of waterproof and rust-resistant materials

- Electrical systems need added protection

- Higher structural and civil engineering requirements

As a result, installing the same type of escalator outdoors can cost 30% to 40% more than indoor installations.

Extra Installation Costs

Note that equipment cost is only part of the total budget. You should also account for:

- Crane lifting and on-site transport

- Structural reinforcement and shaft construction

- Government inspections and safety certifications

- Labor for installation and testing

Ultimately, the total cost will vary based on your project location and on-site construction conditions.

Factors That Affect Escalator Installation Costs

Escalator prices are not fixed—they can vary based on several key factors. Below are the primary elements that influence escalator costs:

Size and Capacity

The size of an escalator directly impacts its manufacturing cost. A standard width is typically 1000 mm, suitable for most commercial and public buildings. If you need a wider escalator—such as 1400 mm—the cost will be significantly higher. Passenger capacity is also critical, especially in larger venues. To handle higher traffic, both the step width and structure need to be increased, which raises the price.

Inclination Angle

Escalator inclination usually ranges from 30° to 35°. A steeper angle moves people faster between floors but needs better design and safety, which raises the cost. As a result, escalators with steeper inclines are generally more expensive than those with standard angles.

Length of the Escalator

The longer the escalator, the higher the cost. Longer escalators, especially those covering several floors, need longer tracks, more power, and extra materials to build.This also raises transport and installation expenses.

Speed

Most escalators operate at speeds between 0.5 m/s and 0.75 m/s. Faster escalators move people more quickly but use more energy and need more complex designs. As a result, high-speed escalators are more expensive than standard-speed models.

Installation Location

Where you install the escalator significantly affects the price. Indoor installations are generally simpler and more affordable. Outdoor escalators need weatherproofing, rust protection, and stronger structures to handle tough conditions, which raises costs. Installing them in old buildings or uneven areas may also need extra work, adding to the budget.

In short, escalator costs depend on factors like size, capacity, angle, length, speed, and where they are installed. Understanding these elements can help you choose an escalator that fits both your operational needs and budget.

How to Reduce Escalator Installation and Operating Costs

Owning an escalator costs more than just buying and installing it. You also need to pay for long-term use and upkeep. Here are several effective strategies to help reduce the total cost of ownership and avoid unnecessary expenses.

1. Choose Energy-Efficient Escalators

In the long run, energy consumption is one of the biggest costs for escalators.

According to Statista, energy usage accounts for 30–40% of total operating costs.

Choosing energy-saving models can significantly cut electricity expenses. For example:

KONE’s EcoMod escalators improve energy efficiency by 20–30%, saving hundreds of dollars per year.

BDFUJI uses energy recovery systems that turn movement into electricity, helping reduce energy waste.

2. Optimize Routine Maintenance

Regular maintenance keeps escalators working well, but doing it too often or poorly can raise costs.

A smart maintenance schedule can reduce service expenses by 15–20%. For example, changing from monthly to quarterly checks and doing them during off-peak hours can cut downtime and labor costs.

3. Use Smart Monitoring and Predictive Maintenance

Modern manufacturers like BDFUJI use IoT sensors in their escalators to check temperature, speed, and vibration in real time.

When abnormalities are detected, the system sends alerts and schedules repair automatically. This predictive maintenance approach catches small problems early, reducing emergency repair costs.

4. Choose the Right Brand and Model

Selecting the right escalator brand and model upfront can greatly reduce long-term costs.

Brands like BDFUJI and Schindler use modular designs and durable materials, resulting in longer lifespans and lower maintenance. For instance, BDFUJI escalators in Southeast Asia malls for over five years have annual maintenance costs of just $1,200–$2,000, much lower than the industry average.

5. Train Operators Regularly

Improper use accelerates wear and tear, raising service costs.

Training staff on basic tasks, such as cleaning comb plates or checking handrail wear, can help extend the equipment’s lifespan. Brands like BDFUJI and OTIS often include free operator training upon delivery.

6. Choose Durable Materials and Local Parts

Select durable, low-maintenance materials like stainless steel steps and abrasion-resistant rubber handrails.

Also, opt for locally available replacement parts to avoid delays and added downtime due to shipping issues.

7. Cut Idle Running Time

Running escalators without passengers wastes energy and causes extra wear.

Installing motion sensors or auto-start features allows the escalator to enter standby mode when not in use. Brands like BDFUJI and KONE offer these features in many of their models.

Reducing the total cost of owning an escalator requires smart choices in equipment, energy efficiency, maintenance, and staff training. With proper planning and management, you can effectively control costs and improve long-term value.

How to Choose the Most Suitable Escalator

Choosing the right type of escalator is crucial for both performance and cost-effectiveness during installation.

Here are five common ways to determine the best escalator for your project:

1. Budget Range

If you need to control initial costs, consider escalator brands that offer essential features at a competitive price. For instance, BDFUJI and Schindler are often more cost-effective compared to others in the same category.

Suggested approach:

Set a budget range for equipment and installation, then select brands and models that fall within that range.

2. Installation Environment

Where you plan to install the escalator matters. Choose the appropriate type based on the setting:

- Indoor commercial space: Standard escalators are enough with lower protection requirements.

- Subway stations or airports: Heavy-duty, weather-resistant models or even double-deck escalators may be required.

- Outdoor spaces: Escalators must be waterproof, dustproof, and corrosion-resistant, with higher design standards.

Suggested approach:

Identify the location and environmental factors, then ask manufacturers for relevant case studies from similar conditions.

3. Passenger Capacity

How many people will be using the escalator? How long will it run each day?

Different brands offer various capacity designs. For example, Thyssenkrupp’s TWIN system is specifically designed for high-density passenger flow.

Suggested approach:

Estimate daily traffic at your site and choose a brand with proven capacity solutions.

4. After-Sales Service Capability

Does the brand have local service teams? Are spare parts readily available?

This directly impacts long-term operating costs and response time during malfunctions. Well-known brands like OTIS and KONE have global service networks, while BDFUJI has established local support in regions like the Middle East.

Suggested approach:

Check if the brand has local service points, supports both in-warranty and out-of-warranty services, and how quickly they respond.

5. Project Timeline and Delivery Speed

Some brands have longer delivery times and are better suited for projects with flexible schedules. If you need fast delivery, focus on brands with inventory or local assembly capabilities.

Suggested approach:

Include “delivery timeline” and “installation schedule” as decision factors when comparing brands.

By evaluating these five aspects, you can make an informed choice that balances performance, cost, and long-term value.

Which Brands Offer the Most Affordable Escalators?

When discussing escalator pricing, it’s important to know how brand choice impacts both cost and quality. Many brands offer different pricing, performance, and after-sales service. To help you find the best value, here are some popular brands known for affordability and their key features.

1. BDFUJI

BDFUJI is a professional manufacturer of escalators and elevator systems, commonly used in commercial buildings and public spaces. Known for high cost-effectiveness, BDFUJI is a popular choice in markets like South America, Southeast Asia, and the Middle East. In a real-world example, a shopping mall cut installation costs by about 30% by choosing BDFUJI escalators. The modular design shortened installation time and reduced labor costs.

Brand Advantages:

- High cost-performance ratio: Affordable pricing with solid performance, perfect for mid-sized malls and transit stations.

- Reliable quality: Key components made from premium materials for long life

- Easy maintenance: Modular design simplifies service and lowers spare parts cost

2. Schindler

Schindler is a leading global elevator and escalator manufacturer, known for premium quality and reliability. Although the initial cost may be higher, its energy-saving features lower long-term operating expenses.

Brand Advantages:

- Durability: Performs well in high-traffic areas

- Energy-efficient: Equipped with smart drive systems to cut power use

- Strong global support: Wide service network for timely maintenance

3. OTIS

OTIS, the world’s largest elevator and escalator manufacturer, offers a range of options from basic models to advanced intelligent systems. OTIS escalators are popular in North America and Europe, often found in high-rise buildings and subway projects. While initial prices range from $150,000 to $250,000, their low maintenance needs and strong after-sales support help lower the total cost of ownership. For instance, in the New York subway, OTIS escalators averaged less than $3,000 per year in maintenance costs over five years.

Brand Advantages:

- High brand recognition: Proven global case studies

- Smart features: Includes auto-fault detection and remote monitoring

- Service accessibility: Wide spare parts availability lowers downtime and costs

4. KONE

KONE is another globally recognized brand, best known for its innovative energy-saving technologies. Its EcoMod system reduces energy use by 20–30%, making it ideal for airports and malls. Though its escalators range from $180,000 to $300,000, the long-term savings in energy and upkeep make it a strong investment.

Brand Advantages:

- Eco-friendly: Energy recovery system reduces power consumption

- Flexible design: Customizable specs and appearance

- Low long-term cost: High-performance engineering and extended warranties

5. Thyssenkrupp

Thyssenkrupp is known for its industrial-grade durability, particularly in heavy-duty environments like airports and train stations. While their units have a higher price, the innovative TWIN system lets two escalators fit in a single shaft, saving space and reducing installation costs. At Dubai International Airport, the TWIN system reduced the number of escalators by 30%, cutting costs.

Brand Advantages:

- High load capacity: Ideal for large-scale, high-traffic buildings

- Space-saving: Innovative shaft-sharing designs

- Controlled maintenance costs: Reliable systems need less frequent service

Each of these brands has its strengths. To choose the most cost-effective option, factor in your project’s budget, site conditions, passenger volume, and long-term maintenance requirements.

How to Choose the Right Escalator Brand

After exploring several affordable escalator brands, let’s examine a real-world example to see how to choose the best brand for your project.

In a shopping mall construction project in Jeddah, Saudi Arabia, the developer considered various brands and ultimately chose BDFUJI escalators. The decision was based on the following factors:

- Limited budget: BDFUJI offered lower procurement costs, reducing the initial investment.

- Stable environment: The project was fully indoors, so weatherproofing and special outdoor features were unnecessary.

- Reliable after-sales service: BDFUJI has a strong global support network, keeping maintenance costs low.

In contrast, for an international airport expansion project in the U.S., the developer chose Thyssenkrupp, mainly due to its TWIN escalator system, which offered higher capacity in limited space. Additionally, Thyssenkrupp’s extensive service network in the Middle East made future maintenance easier.

Quick Selection

Choosing the most cost-effective escalator brand depends largely on the specific environment and budget of your project:

- BDFUJI and Schindler offer strong value for money with low maintenance costs.

- OTIS and KONE are better suited for projects requiring high energy efficiency and advanced smart systems.

- Thyssenkrupp is ideal for locations that need to maximize capacity within tight spaces.

In real-world applications, it’s important to assess your project’s needs as a whole—consider the environment, usage intensity, and budget—to choose the brand and model that provide the best value.

The cost of escalators in modern buildings is a complex and multi-dimensional issue. This guide has covered escalator pricing components, key factors that influence costs, and strategies for reducing expenses.

In upcoming content, we will continue to share more insights about escalators and elevators. Stay tuned with BDFUJI for the latest updates.

FAQ

1. What is the price difference between different brands of escalators?

Escalator prices depend on the brand, specifications, and features. High-end brands like KONE and OTIS typically range from $150,000 to $300,000 per unit, while mid-range brands like FujiHD generally cost between $50,000 and $150,000.

The price difference is mainly due to the following factors:

-

Technology level: High-end brands offer advanced features like intelligent monitoring and energy-saving systems, such as KONE’s EcoMod technology.

-

Durability: International brands often use high-strength steel and premium chains for longer equipment lifespan.

-

After-sales service: Established brands tend to offer long-term maintenance contracts, while smaller brands may only provide basic warranties.

2. Which brand of escalator is the most reliable?

BDFUJI, OTIS, KONE, Schindler, and ThyssenKrupp are among the most reliable brands. These brands hold a significant global market share, and their products undergo strict quality testing, ensuring long service lives and low failure rates.

Choosing a reliable brand can minimize downtime and unexpected failures, especially in high-traffic areas like subway stations and airports.

3. Should I be concerned about the safety of escalators?

Escalators are built to strict safety standards to protect passengers. However, accidents can still happen, typically due to improper use or lack of maintenance.

Key Safety Measures:

-

Emergency stop button: Immediately halts the escalator in case of an unexpected situation.

-

Anti-pinch protection: Guards at the handrail and step interfaces prevent pinching.

-

Speed control: Modern escalators use variable frequency drives (VVVF) to automatically adjust speed based on passenger flow, reducing the risk of falls from excessive speed.

4. What is the usual maintenance and repair cost of escalators?

The annual maintenance cost of an escalator typically ranges from $1,200 to $3,000, depending on the brand, usage frequency, and warranty plan. High-traffic areas like shopping malls and subway stations tend to have higher maintenance costs due to the need for frequent inspections and lubrication.

Maintenance cost components:

-

Periodic inspections: Checking for mechanical wear, chain tightness, and handrail strap condition.

-

Parts replacement: Replacing items such as chains, steps, and control panels.

-

Emergency maintenance: Troubleshooting and replacing parts as needed.

Ways to reduce maintenance costs:

-

Choose energy-efficient equipment: For example, KONE’s EcoMod range reduces wear and tear on the escalator.

-

Sign a maintenance contract: Brands like Schindler and OTIS offer up to 10 years of maintenance service. Regular upkeep can significantly reduce unexpected repair costs.

5. How to use the escalator safely in case of a power failure?

In the event of a power failure, modern escalators typically switch to a battery backup and slow down gradually to prevent passengers from falling. If there is no backup power, the escalator will still stop gradually, avoiding a sudden halt to minimize the risks associated with inertia.