Escalators are the key to moving people safely and quickly in busy places like malls, subway stations, and airports. Escalator installation isn’t your average DIY project. It often takes trained and experienced technicians to install escalators properly. Use this escalator installation guide to help you understand each step of the job.

Steps for Escalator Installation

The process of installing an escalator is as follows:

Prepare drawings → Install the main escalator body → Prepare the site → Measure and mark → Fix the steel frame → Install metal panels → Finish edges → Run test and self‑check

1. Prepare Drawings

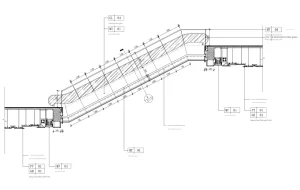

The first step in installing an escalator is to work with the building team, the escalator manufacturer, and the client to make sure the final design meets the building’s needs. During this process, everyone will discuss things like space layout, the number of people using the escalator, and special design requirements. The goal of this stage is to create a plan that is both functional and safe, while making sure it works well with the rest of the building.

When creating the design, we focus on making the system strong, efficient, and safe. It must meet all building codes and industry standards. For example, the escalator design must follow ISO 25745 standards and all local building regulations. We pay special attention to important factors like load capacity, speed, and accessibility to make sure the best vertical transport solution is chosen for the building.

2. Install the Main Escalator Body

Once the escalator installation plan and drawings are finalized, the escalator manufacturer is responsible for the production, installation, and testing of the main escalator. After the escalator passes rigorous testing and complies with relevant standards, the manufacturer will transport the main escalator to the site. The pre-assembled escalator will then be lifted and installed at the designated location. However, the installation process does not end there; a series of additional tasks will follow.

3. Prepare the Site

After the main escalator is installed, we need to check whether the pipes, lighting, and fire sprinkler systems beneath the escalator at the installation site have been installed and tested as required. It is essential to ensure that all related facilities are completed and the construction site is fully prepared. Next, gather the necessary tools and materials for the remaining work and set up the required scaffolding. To ensure the smooth progress of the construction, clear and detailed instructions must be provided to the workers, ensuring that each step is executed according to the standards.

4. Measure and Mark

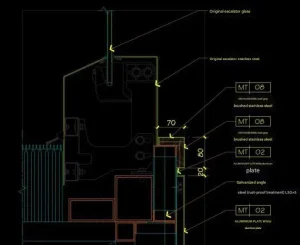

After the escalator attachments arrive, the installation personnel should carefully measure the escalator’s main structure according to the design drawings, marking the sides and bottom of the escalator. This helps accurately determine the dimensions and quantity of the required metal panels.

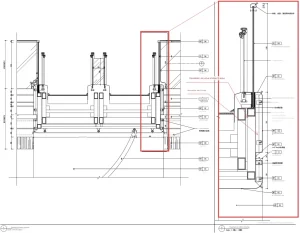

5. Fix the Steel Frame

Once everything is confirmed to be correct, we officially begin the installation process for the escalator attachments. The first step is to install the base plate and securely weld the steel frame onto the escalator body. The steel frame must undergo rust and corrosion treatment, and we also need to check that the frame is straight and stable to ensure its durability.

6. Install the Metal Panels

Next, we will install the LED lights at the bottom of the escalator. The first step is to carefully place and secure the lights. Start by positioning the lights on one side, then on the other side, making sure they are properly aligned. After that, install the curved bottom panels, making sure they fit tightly. Finally, secure the bottom plates by fastening them with special holes or clips. These careful steps ensure both the function and appearance of the escalator after installation.

7. Finish the Edges

Finally, we need to trim the edges, tops, and transitional areas between different materials of the escalator, ensuring that the light strips and panels connect seamlessly.

8. Test and Self‑Check

After installing the escalator, it is crucial to conduct rigorous testing. This phase involves a thorough inspection of the escalator’s dimensions, details, and performance to ensure that all design parameters align with the planned requirements and comply with safety regulations.

Things to Think About Before Installing a New Escalator

While escalators have become common in many public and commercial buildings, most owners or managers don’t have the knowledge to choose, size, and install one by themselves.

That’s why we’re here. Below is a simple summary of the main things to think about when planning a new escalator installation:

Talk with an Escalator Expert

Doing your own research can help, but we recommend asking a trusted escalator professional for advice. An experienced technician can look at your building, the number of people expected, your design choices, and your budget. They can explain which type of escalator works best in places like yours and share examples from other projects.

Companies like BDFUJI are experts in matching the right equipment to your needs and making sure it is delivered and installed correctly for safe and smooth operation.

Get Recommendations and a Cost Estimate

After the installer reviews your site, you’ll get suggestions and a cost estimate. This is a good time to ask questions about energy use, safety features, noise, and design. Always ask for a detailed quote that shows each cost. A BDFUJI expert can offer many escalator models for different types of buildings.

How Long Does It Take?

The time needed depends on the type of escalator and your building. Most typical installations can be done in several days by trained workers. If the site is simple, the work may be faster. More complex projects, like large public spaces, can take longer.

Can I Install an Escalator Myself?

You can research and buy escalator equipment, but installing it is very different. Unless you are a licensed technician with special training, you should not try to install an escalator yourself. Correct sizing, alignment, and safety checks are very important. A poorly installed escalator can be unsafe, cost more money, and cancel your warranty.

Professional Escalator Installation

Professional installation is the safest way to make sure your escalator works well for many years. Licensed technicians have the tools, training, and experience to do the job according to local rules and international safety standards.

What Should We Pay Attention to When Installing an Escalator?

Check the Building Size Many Times

Measure the height, length, support beams, and bottom pit. The top and bottom support beams must stay at a right angle to the escalator’s center line.

Metal Panels Must Meet Design Needs

The type, color, pattern, and quality of panels must match the plan. They need to have product certificates. The frame must also be the right shape and size, and panels must be fixed firmly.

Check While Installing Panels

Use a line to check often so mistakes can be corrected. Bolts must be in the right place to keep the outside looking neat.

Cut Panels Correctly

The size must be exact, and edges smooth. Panels should overlap in the right way, not just touch edge-to-edge. The overlap length must match the plan, and there should be no open gaps.

Protect Panels After Installing

Cover easy-to-dirty parts with plastic film. Add safety boards or railings to protect parts that may get scratched or hit.

Check the Floor and Platform After Work

If there is a height difference or a bad joint between the floor and the escalator cover, fix it right away.

Protect Other Finished Work

Before starting, cover or pad nearby areas. Do not break water pipes, wires, or built-in parts during the work.

Safety of Outer Panels

The panels must be fireproof, look good, and be strong. If 250N of force (about the weight of a person leaning) is pressed on 25 cm², the panels should not break or open a gap.

How Much Does It Cost to Install an Escalator?

The cost for installing an escalator can vary quite a bit. The type of escalator, the size and condition of the site, and how complex the project is will all influence the cost. The price of the escalator itself can change depending on brand, size, and special features. Labor and site preparation also play a role.

Here are some average installation costs for escalators:

Average Installed Cost for a Escalator

Additional labor or building work may increase these costs, especially if steel supports or pit work are required.

| Average Installed Cost | Low End Cost | High End Cost |

|---|---|---|

| $180,000 | $100,000 | $300,000 |

Cost of Installing Escalators in Different Building Types

| Building Type | Typical Height / Capacity | Average Price Range |

| Small shopping mall | 2–3 floors, medium traffic | $120,000 – $180,000 |

| Office building | 2–4 floors, light traffic | $100,000 – $150,000 |

| Large transit hub | 3–6 floors, heavy traffic | $200,000 – $300,000 |

Another factor to think about is efficiency. Higher efficiency models may cost more at first but can provide savings in operating costs over time. If your building only needs to serve one level or a small area, a shorter escalator or moving walkway may be a more affordable option.ion.

Getting an Escalator Installation Estimate

As you consider your options for a new escalator installation, think about which company you want to work with. BDFUJI has years of experience designing and building escalators for different types of spaces. The company continues to develop new technologies that improve safety, performance, and efficiency.

To learn more about escalator installation or our range of escalator products, be sure to connect with BDFUJI. After a site review, you will receive professional recommendations and a detailed cost estimate tailored to your building and needs.

Escalator Installation Layout Method

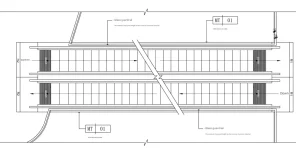

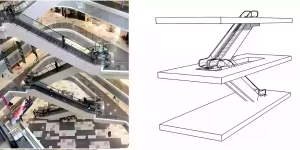

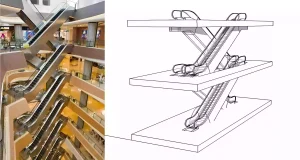

Escalators can be arranged in many ways,Here are the main ones:

Single Escalator (Reversible)

One escalator connects the floors. It can be switched to go up or down depending on traffic. Works for smaller crowds or compact spaces.

Single Escalator with Overlap

A single run that overlaps in the same shaft. It saves space and can be used for advertising panels, but changing direction is less convenient.

Straight‑Through Arrangement

Escalators placed in a straight line, floor after floor. Smooth transfer between levels, often used to pull shoppers quickly into the center of a mall.

Parallel Arrangement (Intermittent)

Two escalators side by side with staggered direction. Not as smooth for transfers, but can move larger flows of people. Common in department stores or exhibition halls.

Parallel Arrangement (Continuous)

Two escalators side by side, both continuously running up and down. Very easy for switching and high capacity. Often found in premium shopping centers.

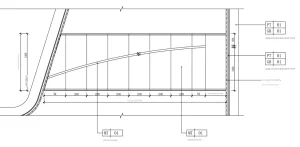

Criss‑Cross Arrangement

Escalators positioned in a criss‑cross pattern. Up and down traffic is separated, reducing crowding at landings and adding visual interest. May block some storefronts.

Split Criss‑Cross Arrangement

Escalators offset in a staggered criss‑cross. Prevents bottlenecks at the landings while also guiding shoppers along certain paths.

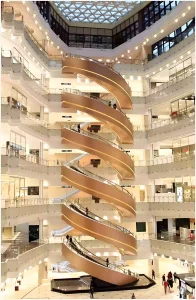

Direct Express Escalator

Curved or Spiral Escalator

A custom design with a curved or spiral form, sometimes used in flagship department stores. Eye‑catching for branding and interior design, but costly to build and maintain.

FAQ

Can You Install an Escalator Outdoors?

Yes, escalators can be installed outdoors. There are specially designed outdoor escalators that use weather-resistant materials (such as stainless steel and anti-corrosion coatings), sealed electrical systems, and enhanced drainage systems to withstand rain, dust, and temperature changes in outdoor environments.

How Long Does it Take to Install an Escalator?

It usually takes about 4 to 8 weeks to install an escalator. The process starts with preparation work, including civil construction, building the escalator pit, and installing the support beams. This phase can take several weeks, depending on the complexity of the site.

After that, the main escalator installation begins. The truss is placed, and the drive system, steps, handrails, and electrical connections are assembled and adjusted. This stage normally takes one to two weeks.

Finally, testing and inspection are carried out to ensure the escalator meets all safety and performance standards. These checks typically take a few days before the escalator is ready for public use.