In a building project, elevators are not as eye-catching as the outside design, and not as strict as fire safety or air conditioning rules. But elevators still matter a lot. The type of elevator you choose will affect the quality of the project, the cost, and how people feel when using it.

In this article, we’ll break down elevator types, how they work, how to choose the right one for your building, and what factors drive cost.

Learn About Elevator Types and How They Work

When people speak about elevator types, they usually mean one of three things: purpose, drive system, or speed. Each perspective tells a different story about how elevators integrate with buildings.

Elevator Classification

Elevators are used in many different ways. Because of this, there are many ways to classify them. Below are the main methods of classification.

By use: Passenger elevators, freight elevators, hospital elevators, dumbwaiters, panoramic elevators, car elevators, ship elevators, construction elevators, and other types of elevators.

By drive system

Screw drive

A motor drives a nut that moves along a screw, creating lifting force and moving the platform up or down.

- Pros: simple design, low cost, small space needed.

- Cons: open platform, loud noise, slow speed (about 0.15 m/s), less comfort, screw wears out.

Drum drive

Works like a winch. The motor winds the rope on a drum to lift the car.

- Pros: simple structure, low cost, the machine can be placed outside the shaft, flexible layout.

- Cons: low speed, rope bends often and wears out, usually needs a gearbox, poor ride comfort.

Chain drive

Uses chains and sprockets, often seen in parking systems.

- Pros: small space, low cost.

- Cons: noisy, poor comfort, needs heavy lubrication.

Hydraulic drive

Uses a hydraulic piston to push the car up and down.

- Pros: low energy use, small pit depth, medium speed, quiet operation.

- Cons: risk of oil leaks, sensitive to temperature, not eco-friendly, has smell, noisy at times, oil system is hard to repair.

Traction drive

Uses ropes or belts and friction with the traction wheel to move the car.

- Pros: low energy use, quiet, smooth ride, high speed, long life, highly automated.

- Cons: higher cost, stronger building requirements compared to screw or chain elevators.

By speed

-

Low speed (below 1.0 m/s)

-

Medium speed (1.0–2.0 m/s)

-

High speed (above 2.0 m/s)

-

Ultra-high speed (above 5.0 m/s)

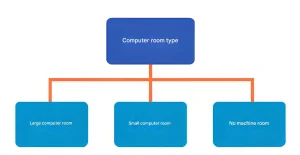

By structure: Machine-room elevators, small machine-room elevators, and machine-room-less (MRL) elevators.

Special-purpose elevators: Explosion-proof elevators for rocket launch bases, anti-corrosion elevators for chemical plants, and moisture-proof elevators for dams.

How Elevators Work

People use elevators every day, but many don’t really know how they move up and down. In fact, the idea is very simple. Let’s take the most common type, the vertical elevator, as an example.

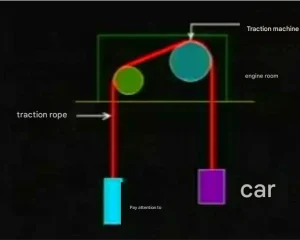

An elevator is made of four main parts: the traction machine, the ropes, the car (cabin), and the counterweight.

The car and the counterweight pull against each other, which keeps the ropes tight in the grooves of the traction wheel. This creates strong friction.

When you press a button, the motor turns the traction wheel. This moves the rope, which pulls the car and counterweight in opposite directions. You can think of the rope like a belt: when the wheel turns, the belt moves, and so does the elevator car.

Check the image below, and you’ll see how simple the principle really is.

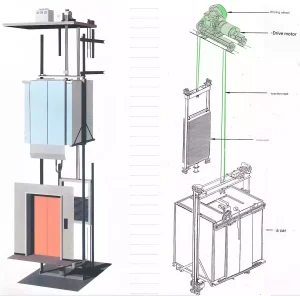

Here are two more pictures to show the principle more clearly.

Major Elevator Brands

The elevator market has many brands, and the competition is strong. If we look at the top 10 brands in the world, the following companies are often seen as leading brands. They supply elevators for hotels, airports, office towers, and other public places. Because they have a long history and a record of quality, they hold large shares in high-end projects:

-

Otis (USA)

-

Schindler (Switzerland)

-

KONE (Finland)

-

Thyssenkrupp (Germany)

There are also other companies that are well-known and widely used in Asia and many other regions:

-

Mitsubishi (Japan)

-

Hitachi (Japan)

-

Toshiba (Japan)

-

Fujitec (Japan)

-

Some British brands

Alongside these global names, there are also fast-growing manufacturers from China. BDFUJI, for example, has earned recognition from a growing number of clients for its traction and machine-room-less (MRL) elevators. These models save space, reduce energy use, and meet international safety standards, making them suitable for both housing and office projects.

How to Design Elevators

Elevator design must follow building codes and standards such as

-

EN 81 in Europe

-

ASME A17.1 in the United States

-

ISO 4190 for standard dimensions

These rules cover safety, size, and performance.

In real projects, most builders use the technical drawings from the chosen elevator manufacturer as the main design basis. If those documents are not yet available, designers can use the common standards.

For example, ISO 4190 gives typical shaft sizes for passenger elevators:

-

An 8‑person (630 kg) elevator often needs a shaft about 2000 mm × 1500 mm.

-

A 13‑person (1000 kg) elevator may need a shaft about 2200 mm × 2000 mm.

For residential buildings, a small 4‑person home elevator may need a shaft around 1400 mm × 1300 mm.

These standard numbers help architects plan the space until the detailed documents from the elevator manufacturer are ready.

Elevator Selection and Cost Analysis

Core Configuration of The Elevator

After choosing a brand, the real skill is how you set the right configuration. Public elevators are mainly used in hotels, office towers, homes, and malls. Even in the same type of building, the needs After you pick a brand, the real test for a buyer is knowing how to choose the right setup. Today, public elevators are mainly used in hotels, office buildings, homes, and shopping malls. Even in the same type of place, the elevator needs can be different based on the project.

High-end hotels, Grade A office towers, luxury homes, and big malls usually use high-end elevators. Smaller projects use simpler ones. Some people think it’s easier to just buy from a famous brand.

But the brand is only a reference. Big brands have basic models, and smaller brands also have high-end models. Don’t focus only on the name—look at the setup.

Choosing an elevator depends on four main things: speed, load capacity, machine room type, and traction motor type.

The faster and stronger the elevator, the more it costs.

Machine rooms come in three styles: big, small, and machine-room-less. Think of it like computers: an elevator with a machine room is like a desktop, and a machine-room-less one is like a laptop. The more compact it is, the higher the price.

There are two kinds of traction machines: old turbine-rotor types and new permanent magnet synchronous types. The new ones save energy, take less space, run smoother and quieter, and don’t need much care. Elevators with the newer motor usually cost about $1,400 to $4,200 more than the old type from the same brand.

Technical Factors in Choosing Elevators

Here are some key points for picking elevators. They may not cover everything, but they are often used in daily work. Cost is also an important part of the decision.

Number of Elevators in High-Rise Buildings

-

For buildings with 12 floors or more, each unit should have at least 2 elevators. On average, each elevator should serve no more than 75 units.

-

For buildings with 25 floors or more, where each floor has more than 5 units, there should be at least 3 elevators. On average, each elevator should serve no more than 70 units.

-

For buildings with 36 floors or more, where each floor has more than 5 units, there should be at least 4 elevators. On average, each elevator should serve no more than 65 units.

Elevator Design Parameters

Choosing an elevator model is a big and complex job. When we decide on the type, we must set key values such as speed, number of stops, travel height, and shaft width and depth. The design should also think about how many people will use it, how long they wait, and the maximum capacity during rush hours. These points help decide the carrying load and other main technical parameters.

Hospital Elevator Requirement

According to common building codes, any high-rise building that requires elevators should have at least one hospital elevator large enough to hold a stretcher. The elevator car should be at least 1600 mm (width) × 1500 mm (depth) or 1100 mm (width) × 2100 mm (depth).

If the car is smaller, the design team must show proof that a stretcher can still fit. They should also mark this clearly in the drawings, including stretcher size, car size, and how the stretcher can move inside.

Noise and Water Protection for Elevators

Elevators in living buildings should not be placed next to bedrooms. If this cannot be avoided, the design should include soundproofing, vibration control, and noise reduction measures.

Elevator halls should not open directly to the outside. Also, the car floor at each stop should be about 15 mm higher than the hall floor, with a small ramp at the doorway for a smooth connection.

Number of Elevators in Super High-Rise Buildings

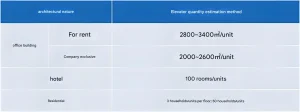

In very tall buildings, the number of elevators depends on how the space is used.

- For offices, about one elevator is needed for every 5,000 square meters.

- In a five-star hotel with 300 rooms, usually four guest elevators are required.

- For apartments in tall towers, normally two to four elevators are needed.

Also, different areas of the building should also have three to four service elevators, and at least one elevator must be designed for fire emergencies.

Deciding how many elevators are needed may look simple, but it actually requires both experience and careful calculation.

For example, in office towers, at least one elevator is needed for every 3,400 square meters. Hotels have lighter traffic, so one elevator for every 100 rooms is usually enough. In housing, the number of elevators depends on the households: one elevator can serve about three families per floor, or about fifty families in total.

Cost Factors in Choosing Elevators

Brand Impact

As explained earlier, elevator prices usually follow brand levels. From top international brands to smaller local brands, the price goes down as the brand level goes down.

If a project has a high position and enough budget, you can choose a first- or second-tier international brand. If the budget is tighter but you still want a strong brand name, you can pick a joint-venture brand, such as Mitsubishi (Shanghai), Thyssenkrupp (Shanghai), Hitachi (Guangzhou), Xizi Otis (Hangzhou), or Toshiba (Shenyang).

In general, the cost difference between international brands, joint-venture brands, and local brands is about $2.8/m² in building area.

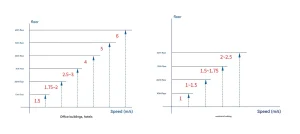

Speed Impact

Elevator speed is set by building height, based on building codes. For housing projects, common speeds are 1.0 m/s, 1.6 m/s, and 1.75 m/s. For super high-rise projects, speeds of 2.0 m/s or 3.0 m/s are used.

The faster the elevator, the less time it takes to reach the floor. But faster is not always better—you must balance speed with cost. Both higher speed and heavier load increase the price.

Elevator speed costs are divided into four ranges:

-

1.75 – 3.0 m/s

-

3.5 – 4.0 m/s

-

5.0 – 6.0 m/s

-

7.0 – 8.0 m/s

Inside each range, price differences are small, usually $14,000 – $28,000 per elevator. But when crossing to a higher range, the cost jumps a lot. For example, moving from 3.0 m/s to 3.5 m/s can add almost $70,000 per elevator.

Load Impact

Elevator load options include 450 kg, 630 kg, 800 kg, 1000 kg, 1250 kg, and 1600 kg. For about 10 people, an 800 kg elevator is enough. In high-rise projects, 800 kg is the standard, while higher-end projects often use 1000 kg.

Machine Room Type

Elevators come with or without a machine room. Projects with strict exterior design or slab-type buildings often choose machine-room-less elevators. For the same setup, a machine-room-less elevator usually costs 5% – 10% more than one with a machine room.

Elevator Emergency Communication System

The elevator emergency communication system connects the car with the control center and maintenance areas. Because it is a key safety feature, it is strongly recommended.

Secondary Decoration

All elevators come with basic decoration, but many projects upgrade them to improve quality. The cost depends on the standard, usually $2,800, $7,000, or $14,000, based on project needs.

Number of Stops

The number of stops means how many floors the elevator must serve. The more stops, the higher the total cost.

Notes for Different Stages of Elevator Installation

Planning Stage

The key points of the elevator building drawings should be written clearly in the design task book and given to the design institute as a guide for construction. Designers must make sure elevator details are shown fully and correctly in the construction drawings.

Early Design Stage

Decide on the elevator manufacturer early, and confirm the main technical parameters. This helps avoid big changes later during the construction drawing stage, which can cause confusion and mistakes in the building plans.

Construction Drawing Stage

The design team should check drawings carefully before release. The elevator company and the design institute should review together to make sure elevator data matches with other drawings (architecture, structure, water, and electrical). This prevents problems such as rework or delays if the design does not fit the elevator installation needs.

Construction Stage

-

Before building starts, the project team should organize a special meeting with the elevator company and the design institute to explain clearly all issues that may affect elevator installation and inspection.

-

Before the elevator is made, if the building work is already finished, the project team, elevator company, construction team, and designers should check the real site together. Any small errors that the elevator company can handle should be solved early, not after the elevator is already produced.

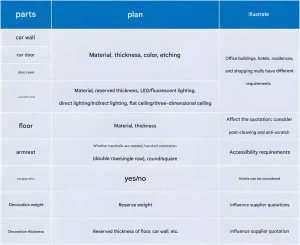

Decoration Choices and Function Options

You can think of it this way: decoration decides how the elevator looks, while functions decide how the elevator works inside.

Decoration choices include the car door, car wall, ceiling, floor, and handrails. Options cover materials, colors, sizes, finishes, and extra add-ons.

The decoration style shapes people’s first impression: a five-star hotel elevator looks rich and fancy, a Grade-A office elevator looks professional, and a luxury home elevator looks stylish and high-quality.

When choosing decoration, remember that it can change the elevator’s weight and space. The elevator supplier should plan for this in advance, leaving room for the extra load and thickness, and then give a full price. Decoration should be reasonable—not too much. For example, handrails are useful for safety, helping seniors and children. But if every elevator is given handrails “just in case,” the extra cost could be tens of thousands of dollars for one project.

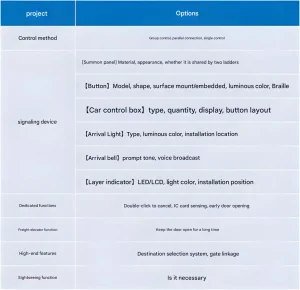

Function options mean special settings for how the elevator works. These include control systems, signal devices, special functions, freight functions, premium features, and sightseeing functions.

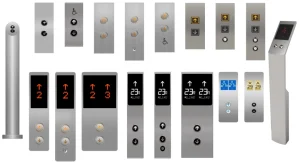

Signal devices have the most choices. A full set includes call panels, buttons, car operation panels, floor lights, arrival bells, and floor indicators. Each part may have several or even more than ten versions. For example, one brand offers 18 types of call panels.

Control systems can be group control, parallel, or single.

Special functions may include double-click cancel, IC card access, or early door opening—often used in hotels. For freight use, you may need a long door-hold option. High-end office buildings may use a destination control system linked to entry gates. In shopping malls, vertical elevators may add sightseeing features.

Just like decoration, more functions are not always better. For example, voice announcement is useful in busy public places like hotels or offices. But adding many rare or low-use functions just to look “high-tech” only wastes money.

Conclusion

The choice and cost of an elevator are closely tied to its functions and technical settings. A single elevator can have hundreds of basic and extra functions. What we listed above is only a small part of all the possible options, but these are the key points that cost managers must focus on.

When choosing elevators for a project, cost planning should start early. The team needs to set the right functions and parameters based on the project’s goals. This way, the elevators will meet quality and safety needs, while also helping to save money and improve efficiency.

👉 With solutions ranging from residential elevators to freight and panoramic elevators, BDFUJI offers international clients a flexible portfolio. Its traction and MRL elevators in particular have become popular for projects seeking a blend of cost efficiency, reliability, and global safety compliance.