Elevators, as an indispensable vertical transportation tool in modern buildings, are gradually becoming the focus of public attention.

With the enhancement of awareness, people are placing increasing importance on elevator brands, performance, models, safety, after-sales service, and so on.

However, even so, not many people realize that the lifespan of an elevator is also limited.

Lifespan of Different Types of Elevators

Not all elevators have the same lifespan. Different types of elevators have significant differences in lifespan due to their design structure and operating environment.

Residential Elevators

Average lifespan: Around 20 to 25 years

Product Overview:

Residential elevators are specifically designed for intermittent use in private homes. They are intended to serve a limited number of passengers and are tailored based on space and aesthetics. Their lifespan depends on meticulous maintenance and avoiding overloading during use.

Advantages:

-

Can be customized based on household needs

-

Quieter operation and lower energy consumption

-

Minimal wear and tear due to infrequent use

Disadvantages:

-

Lower load capacity and speed

-

Prone to being overlooked if not part of regular home maintenance

-

Higher cost per use due to non-commercial nature

When to Consider Replacement:

If your residential elevator shows delayed startup, increased noise, or lacks modern accessibility features, it indicates component aging. Frequent service calls or declining operational smoothness may signal the end of its service life.

Commercial Elevators

Average lifespan: Typically 25 to 30 years

Product Overview:

Commercial elevators are the lifeline of high-traffic buildings. Built with reinforced frames, sturdy cables, and heavy-duty motors, they are designed to withstand frequent cycles. However, continuous usage inevitably leads to mechanical fatigue.

Advantages:

-

High load capacity to meet large passenger flow

-

Compatible with modern control systems

-

Engineered for intensive and repetitive operation

Disadvantages:

-

Requires more frequent maintenance intervals

-

Higher energy consumption

-

Susceptible to regulatory obsolescence if not updated

When to Consider Replacement:

Signs such as uneven floor leveling, delayed acceleration, or non-compliance with current safety standards are red flags. If your equipment uses outdated digital interface technology or lacks energy-saving motors, modernization or complete replacement is not only advisable but essential.

Hydraulic Elevators

Average lifespan: Generally 20 to 25 years

Product Overview:

Hydraulic elevators are commonly found in low-rise buildings, operating based on pressurized fluid mechanics. Although easier to install, their lifespan is often affected by temperature fluctuations and humidity.

Advantages:

-

Simplified installation without overhead machinery

-

Cost-effective for buildings with fewer floors

-

Smooth and quiet short-distance travel

Disadvantages:

-

Prone to oil contamination and leakage

-

Component performance easily declines in humid or corrosive conditions

-

Not suitable for mid- or high-rise buildings

When to Consider Replacement:

If you notice unstable leveling, oil stains, or delays between floor commands and cab movement, the internal systems (e.g., piston or valve unit) may be on the verge of failure. Upgrading is crucial to prevent major breakdowns.

Traction Elevators

Average lifespan: Up to 30+ years

Product Overview:

Traction elevators are the backbone of mid- to high-rise buildings. They utilize ropes and counterweights to deliver precise movement and excellent energy efficiency. Their construction incorporates advanced technology and long-term performance.

Advantages:

-

Exceptional durability and mechanical resilience

-

Ideal for taller, high-usage buildings

-

Accommodates regenerative drives and smart controllers

Disadvantages:

-

Higher complexity in initial installation

-

Requires dedicated overhead space (machine room or MRL variant)

-

Higher cost for modernization or rewiring

When to Consider Replacement:

Noisy gearboxes, rough stops, or increased downtime typically suggest worn traction sheaves or motor encoders. If usage remains steady but energy bills increase, it may indicate aging motors or control systems.

Passenger Elevators (Compact Type)

Average lifespan: 15 to 20 years

Product Overview:

Compact passenger elevators are often installed in private homes or small facilities. They are designed to minimize spatial impact and are a lifeline for the elderly or people with mobility issues. However, they require delicate handling and regular calibration.

Advantages:

-

Fits into existing residential layouts

-

Enhances accessibility in multi-level homes

-

Quiet operation with very low power consumption

Disadvantages:

-

Smaller cab size and reduced capacity

-

More sensitive to maintenance oversights

-

Limited upgrade options after installation

When to Consider Replacement:

Watch for frequent sensor failures, unresponsive panels, or noticeable cab vibrations. With technological progress, compact elevators lacking emergency communication or smooth leveling mechanisms become prime candidates for overhaul.

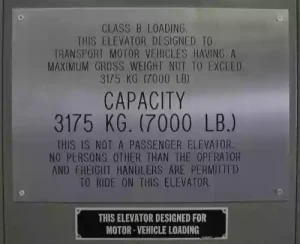

Freight Elevators

Average lifespan: 20 years or more, depending on loading conditions

Product Overview:

Freight elevators are built to transport heavy goods, functioning like a robust machine. Their design prioritizes utility over aesthetics. Structural integrity is critical—but relies on strict adherence to load guidelines.

Advantages:

-

Sturdy construction suitable for industrial use

-

Larger platforms for non-human cargo

-

High weight thresholds

Disadvantages:

-

Typically slower travel speed

-

Loud operation and less refinement

-

Sacrifices aesthetics for functionality

When to Consider Replacement:

Frequent overloading, rusted shaft doors, or vibrations under load are clear indicators. If your freight elevator becomes increasingly unstable in daily use, its internal frame may have reached the fatigue threshold

Factors Affecting Elevator Lifespan

Elevator Usage Frequency

An elevator is a highly coordinated mechanical system. Every start, stop, and door movement causes wear and tear.

In busy office buildings, malls, or hospitals, elevators may run hundreds of trips daily. This high-frequency usage gradually wears down key components, especially braking systems, door operators, and cables. Without regular inspections and part replacements, elevator lifespan shortens significantly, increasing the risk of early failure.

Overloading the Elevator

Exceeding the maximum load capacity is not only unsafe but also severely impacts the elevator’s lifespan. Constant overloading damages performance, compromises structural integrity, and leads to early system failure. Load protection and warnings are essential to preserving lifespan.

Elevator Installation Accuracy

Installing an elevator is not simply about “putting it in”; it’s a precision tuning process.

If the shaft is rough, bolts are loose, or parts are misaligned—small issues like these can result in frequent malfunctions later.

A professional installation requires millimeter-level precision. Every bolt must be perfectly tight, and each part must be aligned, secured, and tested to ensure smooth and safe long-term operation.

Environmental Impact

Environment is one of the key factors affecting an elevator’s lifespan.

For instance, coastal environments with salty air accelerate component corrosion.

Humidity causes oxidation and rusting of parts.

Extreme temperatures can damage lubricants and severely affect electronic control systems. To mitigate environmental wear, durable and adaptive materials should be used.

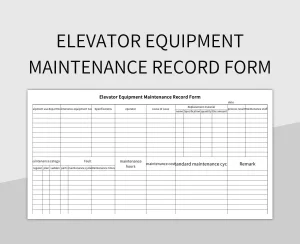

Elevator Maintenance

Like people, elevators also need “regular check-ups.”

Professionally maintained elevators usually run more smoothly and break down less often, with a lifespan extended by 5 to 10 years beyond average.

For example, quarterly inspections, timely part replacements, and regular system calibration—though seemingly minor steps—are the secret to long-lasting elevators.

Conversely, skipping inspections or ignoring broken parts is like making the elevator “work while ill,” leading to inevitable early failures.

How to Determine if an Elevator Needs Replacement

As elevators begin to show signs of aging, many small details expose underlying problems. Determining whether an elevator needs replacement depends on recognizing these signals to make timely decisions for safety and performance.

Frequent Elevator Failures

If your elevator breaks down several times a year, it’s likely heading toward “early retirement.”

Constant patching may seem like saving money, but it’s actually an expensive and unreliable repair cycle. Frequent failures suggest that even after each fix, the next problem is just around the corner.

Rather than worrying and spending endlessly, it’s wiser to choose modernization or full replacement—a safer and more cost-effective solution.

Persistent Unusual Noises

If your elevator starts making continuous clicking or humming noises, it may signal impending major faults.

These sounds could originate from misaligned pulleys, fatigued motors, or failing bearings. What sounds like noise is actually the elevator “crying for help.”

Ignoring these warnings can lead not only to annoyance but also to shutdowns or safety hazards.

Slow or Unstable Operation

If the elevator consistently reaches floors slower than expected or shakes while rising, it likely has calibration issues or a weakening drive system.

Smooth elevator operation is not just about appearance—it reflects the synergy of all mechanical components and the true health of the system.

Outdated Elevator Technology

Elevators over 20 years old typically lack essential features, such as bidirectional emergency communication, energy-saving drives, or contactless control. In today’s world, where safety and convenience are paramount, upgrades are not just for appearance—they’re a necessity.

How to Extend the Lifespan of Elevators

Understanding the factors that affect elevator lifespan allows us to take proactive and effective measures to delay aging and ensure safe, stable operation. Here are some practical ways to extend elevator service life:

Schedule Regular Inspections

Establish routine maintenance plans. Certified elevator technicians should conduct on-site inspections monthly or quarterly to identify issues before they worsen. This proactive approach is the foundation of long-term durability.

Lubricate Moving Parts

Insufficient lubrication is a silent enemy. It increases friction, causes parts to overheat, and accelerates wear. Use manufacturer-approved lubricants for gears, rollers, and door operators.

Replace Worn Parts Promptly

Replace worn rollers, bearings, or cables at the first sign of fatigue. Waiting for a major failure leads to higher costs and greater risk. Preventive maintenance saves money and avoids emergencies.

Maintain Shutdown Logs and Records

Plan downtime for major upgrades and keep detailed logs of all maintenance activities. These records help identify persistent issues and assist in future budgeting.

Promote Safe Daily Usage

-

Respect Weight Limits: Elevators are not freight lifts. Clearly post load limits and inform tenants or staff—especially during moving or delivery.

-

Use Controls Gently: Encourage soft, mindful button presses. Many panel faults are caused by repeated rough use.

-

Report Abnormalities Immediately: Even small issues—such as door delay or faint knocking—should be addressed quickly. Early intervention prevents escalation.

-

Educate Residents: In residential buildings, especially with children or elderly, post elevator signs and hold briefings to encourage safe habits.

BDFUJI Empowers the Future of Vertical Movement: Precision Meets Progress

At BDFUJI, we don’t just replace elevators—we redefine them. Whether you’re looking to refresh an aging system, enhance safety compliance, or embrace cutting-edge technologies, our customized modernization solutions blend architectural elegance with engineering precision.

We offer:

-

Tailor-made modernization blueprints for your building’s unique needs

-

Energy-efficient retrofits for long-term savings

-

Stylish, forward-thinking cab upgrades that reflect modern aesthetics

-

Full compliance with EN standards and global safety codes

Book a free assessment today—and let BDFUJI bring new life to your building’s vertical transportatio

FAQs

How long does a full elevator replacement take?

Typically, 4 to 6 weeks, influenced by shaft readiness, structure complexity, and customization needs.

Is modernization a viable alternative to replacement?

Absolutely. Upgrading controllers, door systems, or interiors can restore full operational integrity and extend lifespan by 10 to 15 years.

Is elevator maintenance legally required?

Yes. Most jurisdictions mandate annual inspections by certified professionals. Violations may result in fines or shutdowns.

How much does elevator modernization cost?

Prices range from $15,000 to over $100,000, depending on project scope, building type, and system requirements. BDFUJI offers tailored pricing based on your budget and expectations.

BDFUJI is committed to delivering safe, advanced, and sustainable elevators. Contact us for a personalized consultation to build your future elevator system.