When it comes to selecting an elevator, cost is often one of the most critical factors to consider. For developers, construction companies, or homeowners, elevators are not only essential for the building’s function but also contribute significantly to the convenience of use and the property’s overall value. With so many types and brands of elevators available, the market offers a wide range of options with varying price points. Understanding the minimum cost of an elevator, along with the factors influencing it, will help you make a more informed decision, especially when working within a tight budget.

This guide is intended for anyone or any company considering an elevator installation. Whether you’re a builder, developer, property manager, or an individual with a basic understanding of elevator systems but looking to optimize costs, this article will provide you with practical cost insights and tips for saving money.

Elevator Minimum Cost

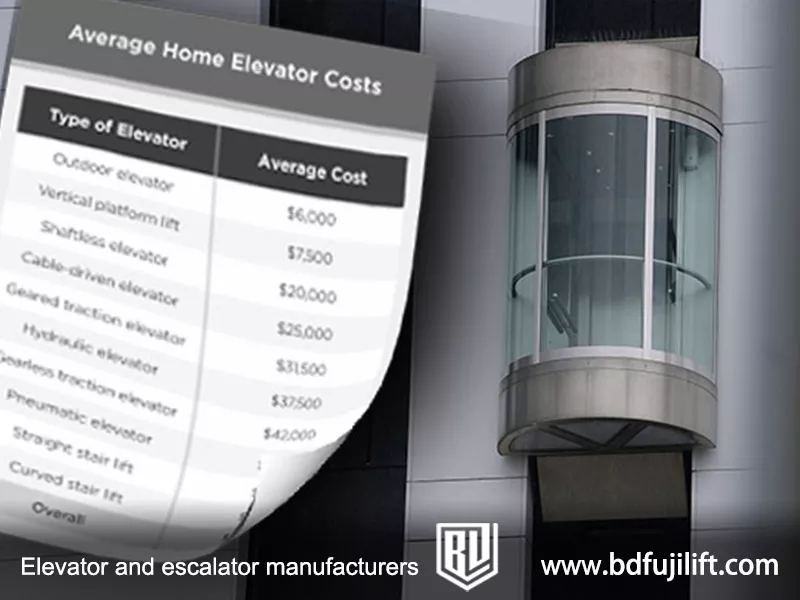

The minimum cost of an elevator typically depends on the type of elevator and the installation environment. Depending on your needs, the price range for a basic elevator is generally as follows:

- Home Elevators: The lowest price generally ranges between $5,000 and $10,000.

- Commercial Elevators: The starting price usually falls between $20,000 and $30,000.

- Freight Elevators: The minimum cost tends to range from $15,000 to $25,000.

The price of the least expensive elevator is typically determined by several factors, such as the type of elevator, installation requirements, and necessary features.

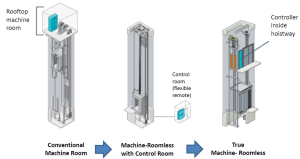

Hydraulic elevators, for instance, are often cheaper than traction elevators, mainly because they are easier to install and are ideal for low-rise buildings. Traction elevators, in contrast, are better suited for high-rise buildings. Their installation is more complex, which makes them more costly. Standard-sized elevator systems are usually more budget-friendly than custom-made models, allowing you to stay within your budget while still meeting basic functionality requirements.

Another benefit of opting for a low-cost elevator is that its maintenance costs are typically lower as well. This is because these elevators have simpler designs and fewer features, making them easier to maintain. However, while they may meet basic functional needs, these low-cost elevators might compromise on speed, comfort, and energy efficiency, particularly in high-rise or high-traffic environments, which could lead to increased maintenance needs over time.

What Determines the Cost of an Elevator?

Elevator costs can be categorized into three main groups: lowest cost, average cost, and high-end custom elevators. The lowest-cost elevators are typically for projects where budget constraints are a major concern and where the building’s elevator needs are relatively simple. These elevators are designed with cost-saving in mind, focusing on providing the most essential functions and safety features. Although they tend to have fewer extra features, they can still meet the needs of most low-rise buildings or locations with low traffic.

On the other hand, standard elevators strike a better balance between performance, quality, and price. These elevators are generally a suitable option for both commercial and residential projects and tend to be the most cost-effective choice. High-end elevators, however, are often customized to meet more specific needs, such as comfort, aesthetics, and advanced functionality. These elevators not only prioritize practicality but also focus on providing a more luxurious experience.

The total cost of an elevator goes beyond just the type and configuration. Installation costs, equipment procurement, and ongoing maintenance costs all factor into the final price. Installation expenses are influenced by the type of elevator, the structure of the building, and how complex the installation is. Hydraulic elevators are usually installed in low-rise buildings due to their straightforward setup, while traction elevators are required for taller buildings, which involve more complicated installation procedures.

The cost of procuring elevator equipment is influenced by the brand, model, and the specific features you want. Premium brands often charge higher prices due to their unique technologies and designs. Additionally, maintenance costs should be factored into long-term budgets, especially for frequently used elevators. Regular maintenance can not only extend the life of an elevator but also reduce the likelihood of unexpected failures, which helps control long-term operational costs.

Minimum Cost of Different Types of Elevators

Now that we’ve covered the general structure of elevator costs, let’s dive deeper into the minimum price ranges for various types of elevators. Elevator prices can vary depending on the intended use, design specifications, and installation environment. Here’s a breakdown of the minimum cost range for some common types of elevators:

Commercial Elevators

Commercial elevators are typically used in large buildings like office towers, shopping malls, and hospitals. These elevators generally require higher load capacities and are used more frequently. For example, in a recent UAE project we participated in, we installed a commercial elevator for an office building at a minimum cost of approximately $20,000 to $30,000. These elevators are ideal for low-rise buildings, as they effectively meet typical commercial needs and comply with modern energy efficiency standards.

Home Elevators

Home elevators are primarily installed in residential homes, especially for families with space limitations or a need for a smooth, quiet ride. For example, in a recent residential project, the minimum cost for a home elevator ranged from $10,000 to $20,000. These elevators are designed to meet the needs of families and maximize space efficiency while ensuring comfort and safety.

Home elevators tend to have low maintenance costs. They typically require just annual inspections and have excellent operational stability once installed, making them ideal for homes that need space-saving solutions and long-term reliability.

Freight Elevators

Freight elevators are designed to carry heavy goods and are often used in warehouses, factories, and other industrial locations. In a recent logistics project, the minimum price for a freight elevator was around $15,000 to $25,000. These elevators must handle higher load requirements and must be installed according to strict safety standards to ensure long-term reliability and stability.

Hydraulic Elevators

Hydraulic elevators are generally used in low-rise buildings, where the installation process is simpler and more affordable. In a commercial low-rise building, the minimum cost for a hydraulic elevator typically ranges from $15,000 to $20,000. These elevators provide smooth operation, are easy to install, and operate quietly.

However, compared to traction elevators, hydraulic models have limitations in terms of load capacity and speed. As such, they are often more suitable for low-rise buildings or smaller commercial spaces, where budgets are more constrained.

Traction Elevators

Traction elevators are commonly found in medium- to high-rise buildings. These elevators offer faster speeds and higher load capacities. For example, in a high-rise office building project, the minimum cost for a traction elevator is typically around $20,000 to $30,000. These elevators are best suited for environments that require high speed and capacity, especially in areas with heavy foot traffic and frequent use.

While the initial investment for traction elevators is higher, their efficiency and durability make them a popular choice for skyscrapers and other long-term investments.

Effective Factors in Reducing the Overall Cost of Elevators

When selecting an elevator, there are several factors to consider that can help reduce the overall cost. By making smart choices in terms of design and specifications, you can meet your needs while staying within your budget.

Choosing Standard Sizes and Pre-Configured Models

Opting for standard sizes and pre-configured elevator models is one of the most effective ways to reduce costs. Compared to customized designs, standard elevators don’t require additional time for design and production, leading to significant savings. For example, in a commercial building project, choosing a standardized design saved us around 15%-20% compared to a custom solution.

Minimizing Pit and Shaft Requirements

The design of the pit and shaft plays a crucial role in elevator installation costs. Keeping these requirements simple during the building design phase can significantly lower construction costs. In a recent project for a low-rise office building, simplifying the shaft structure reduced installation costs by approximately 10%-15%.

The Impact of Building Height on the Budget

Elevator systems cost significantly more in high-rise buildings due to the need for higher operating speeds, greater load capacities, and additional safety features. For example, installing an elevator for a mid-to-high-rise commercial building can be 25%-30% more expensive than for a low-rise building due to these heightened requirements.

Choosing Manual Doors and Basic Cab Interiors

Opting for manual doors and basic cab interiors can drastically reduce the overall cost of the elevator installation. Although manual doors sacrifice convenience and automation, they are a good choice for budget-conscious projects, especially in low-rise buildings or less-frequented spaces. Similarly, choosing a simple interior design can lower manufacturing costs and simplify future maintenance.

Shared Facilities in Multi-Unit Buildings

In multi-unit buildings, sharing an elevator system between multiple units is an effective way to reduce the installation cost for each individual unit. For example, in an apartment building, sharing the elevator system between units significantly cuts down the overall cost. This approach not only works for projects with limited budgets but also satisfies the basic needs of each unit while improving operational efficiency.

How to Find a Low-Cost Elevator Supplier

Finding the right elevator supplier goes beyond just choosing the lowest-priced option. Long-term maintenance and service quality are crucial, so it’s important to find a supplier that offers good value for money. Here are some strategies for finding a cost-effective supplier:

Time Your Purchase for Discounts

Timing your purchase can be a game-changer when it comes to reducing costs. Many elevator suppliers offer discounts during year-end promotions or at large industry trade shows. During these periods, you can not only enjoy lower prices but also gain access to additional services or warranties. For example, when we purchased elevators for a shopping mall during a trade show, we secured savings of 15%-20%.

Choose a Trustworthy Supplier for Installation

Selecting a reputable elevator installation supplier is key to ensuring your project is completed smoothly. A reliable supplier can offer high-quality elevators and help keep installation costs within budget. By checking customer reviews, asking about past projects, and engaging in thorough communication, you can identify suppliers who deliver both quality and value. In many of our projects, we worked with suppliers who not only ensured timely delivery but also avoided unnecessary costs through efficient budget planning.

Master Negotiation Skills

Requesting quotes from multiple suppliers and comparing them is an effective way to find the best price-to-performance ratio. By understanding market conditions, clearly defining your needs, and maintaining good communication with suppliers, you can negotiate for more favorable terms. When selecting a supplier for a residential project, we successfully negotiated a price reduction and secured additional discounts on ongoing maintenance.

Final Thoughts

The lowest-cost elevator typically offers only the basic functionality and fewer added features. However, this doesn’t mean they can’t meet essential needs. For environments with low traffic or limited usage, a low-cost elevator can still provide reliable service and meet basic transportation needs. Nonetheless, these elevators may come with certain reliability and safety risks. When choosing, it’s important to balance your budget with elevator performance.

Although low-cost elevators offer an affordable initial investment, they may compromise safety and operational efficiency. Over time, they may require more frequent maintenance, increasing long-term operating costs. In many cases, opting for a slightly higher-priced elevator could offer better value, providing greater reliability and fewer maintenance needs.

Additionally, even if you choose a low-cost elevator, ensure that it has room for upgrades and access to future technical support. This will not only extend the elevator’s lifespan but also allow for future technology upgrades to improve overall efficiency.