Do you know what happens if an elevator machine room is poorly designed?

When an elevator machine room is poorly designed, you may face safety risks, higher costs, and even unexpected breakdowns.

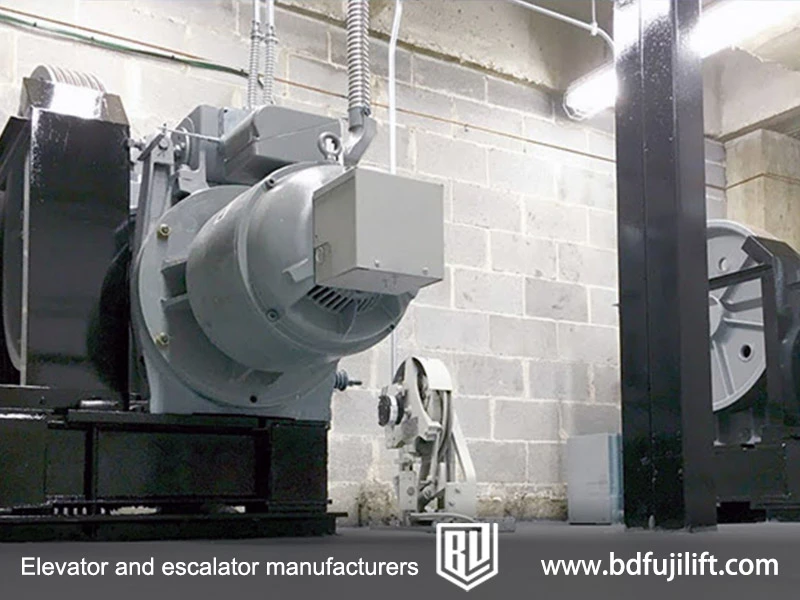

Many builders and managers face these problems because they do not realize this room is the true “brain and heart” of the elevator. It is where the motor, controller, and safety parts work together to give power, control, and protection so passengers can move safely between floors.

Next, let us take a closer look at the elevator machine room.

What Is an Elevator Machine Room?

An elevator machine room is a special space that holds the main drive and control equipment for the lift. It supplies the power, direction, and safety functions that keep passengers moving between floors. In most buildings, the elevator machine room is at the top of the shaft, in the basement, or sometimes on the side of the shaft. Think of it as the command center that makes sure the elevator runs as it should.

Inside an elevator machine room you will usually find the controller, the motor, circuit breakers, and other parts. The controller is the most visible piece of equipment. It sends the car to the right floor and controls the motor. The motor provides the lifting power that moves the cab up and down. Circuit breakers manage power supply, one for the motor itself and another for systems like emergency lights. You will also see safety parts such as brakes and limit switches, which protect passengers by stopping the elevator if something goes wrong. These parts work together to keep travel smooth, reliable, and safe.

What Do Elevator Machine Room Signs Look Like

Elevator machine room signs warn about electrical danger, limit access to trained staff, and help emergency teams or technicians find the room quickly. They are also required by safety codes, making sure the machine room can always be identified without delay. Because of this, their design must be clear and easy to see.

Most of them are rectangular with bright colors such as yellow, red, or white on a dark background.

They often include words like “Elevator Machine Room,” “High Voltage,” or “Authorized Personnel Only.”

Many signs also feature simple safety symbols, for example a lightning bolt for electricity or a red circle with a line across it to show restricted entry.

These markings are not just decoration. They warn about danger, keep out untrained people, and guide rescue teams or technicians to the right place in an emergency.

A clear, visible sign can make the difference between a quick response and wasted time.

Types of Elevator Machine Rooms

Elevators with a Machine Room (MR)

In a traditional elevator, all the driving and control equipment is stored in a dedicated elevator machine room. This room acts like the elevator’s brain and heart.

The most common location is on the top floor of the building. This makes repair and maintenance easier because technicians can go straight to the top and check the system without disturbing the rest of the building. The open space also helps with cooling. The downside is that the room at the top may get too hot in summer or too cold in winter, which can affect the equipment.

Sometimes the elevator machine room is in the basement. This avoids weather problems but makes the shaft longer, which can raise building costs.

In some high-rise buildings, the machine room may be set in the middle floors. This helps balance the elevator’s weight and reduces stress on the building. But it makes access harder for repair staff.

In rare cases, the elevator machine room is built outside the main building or in a separate basement structure. This gives the most design freedom, but it increases costs and takes more land.

Machine Room-Less Elevators (MRL)

Machine room-less elevators save space by putting the motor and control panels inside the shaft or in a small cabinet near the elevator. For example, some MRL elevators have their equipment inside the door frame, while others keep it in a closet close to the shaft.

In one case study, the control boxes were placed right next to the elevator. One box handled the main power, while another box handled ventilation and lights. The main power usually has a higher voltage, while the lights and fans are below 200 volts. In emergencies, keeping lights and ventilation on is important so passengers do not panic.

MRL elevators are popular because they save space and look clean inside the building. But they can be harder to service, since there is no large elevator machine room for equipment.

Hydraulic Elevator Machine Rooms

Hydraulic elevators usually keep their pump, oil tank, and controller in a small elevator machine room near the shaft or in the basement. One of their biggest advantages is cost. They are usually cheaper to install than MRL elevators. They also have very strong lifting power, which makes them useful for moving heavy loads in low- to mid-rise buildings or freight elevators. Their simple design also makes them easier and cheaper to maintain.

But hydraulic elevators are not as energy efficient as MRL systems. They use more power, make more noise, and need extra space for oil storage and cooling. This means the hydraulic elevator machine room must be carefully planned to ensure safety and performance.

What Are the Requirements for Building an Elevator Machine Room?

Size Requirements for Elevator Machine Rooms

Every elevator machine room must provide enough space and height to let technicians work safely and comfortably. Without enough clearance, technicians cannot work safely. In California, rules need a least height of seven feet, or about 2.1 meters. In practice, eight feet is better, since it allows good lighting and airflow.

International standards give more exact numbers:

-

United States (ASME A17.1): Height at least 2.1 meters; space of 0.9 meters around the equipment; doors at least 0.76 meters wide and 2 meters high.

-

Europe (EN 81-20): Least height of 2 meters; space of 0.5 meters; doors at least 0.6 meters wide and 1.8 meters high.

-

China (GB 7588-2003): Least height of 2 meters; space of 0.5 meters; doors at least 0.6 meters wide and 1.8 meters high.

Sometimes, older buildings do not meet these rules. In such cases, custom solutions are needed. BDFUJI has worked on special projects where the elevator machine room height was only 1.5 meters, yet still provided a safe design.

Access Requirements for Elevator Machine Rooms

Access to an elevator machine room must be safe, clear, and secure. Doors should open outward and be wide enough for equipment to pass through. They must be lockable to keep out unauthorized people, yet easy for technicians and emergency teams to use in an emergency. Pathways leading to the room should also stay clear at all times to ensure quick entry when needed.

Electrical Requirements for Elevator Machine Rooms

Electrical systems in an elevator machine room must meet clear standards. Power supplies are typically 220V for lighting and extra systems and 380V/480V three‑phase for the main drive motor. Grounding resistance should normally be less than 4 ohms to keep people safe. Circuit breakers must be labeled for the motor, controller, and emergency lighting. ASME A17.1 and EN 81-20 both say that electrical panels must be easy to reach and protected from water and dust. No unrelated equipment such as IT servers or office wiring should be installed here, since it can interfere with safe elevator operation.

Lighting and Ventilation Requirements for Elevator Machine Rooms

Good lighting and airflow are needed for safe work inside the elevator machine room. Lighting levels should reach at least 200 lux so that technicians can see clearly during inspections and repairs. Emergency lighting should also be installed to give visibility during power outages.

Ventilation in the elevator machine room must keep the temperature steady, preventing overheating of motors and control systems. Natural ventilation may be enough in small rooms, but in larger or taller buildings mechanical ventilation or air conditioning is often needed to keep the temperature between 5 and 40°C and to control humidity.

Fire Safety Requirements for Elevator Machine Rooms

Fire protection in an elevator machine room is important to prevent damage and protect both people and equipment. At least one dry powder fire extinguisher must be installed, and larger rooms may need two or more units placed near the entrance and next to main equipment for quick access. Sprinklers are usually not allowed because of the electrical systems. Walls and doors must provide a fire resistance rating of 60 to 120 minutes depending on local code. For example, ASME A17.1 in the United States and EN 81-20 in Europe both set least fire protection standards to make sure the machine room can contain a fire long enough for safe exit and equipment protection.

Conclusion

The elevator machine room is more than a hidden technical space. It is the core of safety and performance for every elevator system. Careful planning of the elevator machine room lowers risks, improves smooth operation, and extends equipment life. Whether you choose a traditional MR, a space-saving MRL, or a cost-friendly hydraulic system, understanding the requirements will help you make the right choice. BDFUJI provides solutions for all three types of elevators and specializes in custom projects, making sure that even unusual spaces can support safe and reliable elevator systems.

FAQ

What is the difference between MR and MRL elevators?

MR elevators need a separate elevator machine room, while MRL designs do not. MR designs provide more space for technicians to work, while MRL systems save building space but can make maintenance more complex. For example, in a high-rise office tower, an MR elevator might be easier to service quickly, while in a compact residential building, an MRL can be a better fit.

Do elevator machine rooms need sprinklers?

In most cases, sprinklers are not allowed because water can damage electrical systems and increase the risk of shock. Instead, safety codes need dry powder fire extinguishers or other non-water systems. For example, NFPA standards and ASME A17.1 both highlight the use of extinguishers in machine rooms rather than sprinklers.

Do elevator machine rooms need fire ratings?

Yes. In most regions, building codes need elevator machine room walls and doors to have a fire resistance rating of one to two hours. This protects both people and equipment in case of a fire. For instance, EN 81-20 in Europe and GB 7588 in China both set least fire resistance levels, ensuring the machine room can contain a fire long enough for safe exit.