Elevator dimensions are not small details. They shape how people move in a building, how safe it is in emergencies, and whether the project meets code. An elevator that is too small may block a stretcher during rescue. One that is too large may waste shaft space and increase energy bills.

This guide explains the essential sizes for all main elevator types, following international codes such as EN 81 (Europe), ASME A17.1 & IBC (USA), and ADA (Accessibility).

Elevator dimensions international standards

Elevator dimensions are set by strict codes around the world. Some of the most common rules are:

EN 81-20 (Europe)

Passenger elevators in public buildings must have a cab height of at least 2.0 m. The door opening of a standard elevator must be no less than 0.80 m. For machine-room projects in high-rise buildings, the machine room must have fresh air and daylight, and water pipes cannot pass through.

EN 81-70 (Europe)

At least one elevator in every public-use building must be wheelchair accessible. In new buildings, the door clear width must be at least 0.90 m. The cab must also allow a 1.50 m turning circle so a wheelchair can turn inside.

IBC & ASME A17.1 (United States)

Residential towers with many floors must include one stretcher-sized elevator large enough to fit an ambulance stretcher (610 × 2130 mm / 24 × 84 in). A firefighter elevator must reach the top floor in 60 seconds or less and carry at least 800 kg (1750 lbs).

ADA Standards (United States)

Accessible elevators must place call buttons between 890–1220 mm (35–48 in) from the floor. They must use both lights and sounds to show arrival and direction. Inside accessible cabs, the control panel buttons must be no higher than 1220 mm (48 in) so wheelchair users can reach them.

Elevator Cab, Shaft, and Door Sizes

Always finalize shaft size before construction. Many delays happen because architects only consider cab size and forget shaft clearances. The shaft must be larger than the cab to allow space for rails, counterweights, wiring, and clearances.

-

Shaft width = cab width + ~700 mm

-

Shaft depth = cab depth + ~600 mm

-

Door width = cab width – ~200 mm

Example: A cab of 1.60 × 1.40 m for a 1000 kg passenger elevator requires a 2.15 × 2.20 m shaft. If the shaft is built smaller, the elevator cannot be installed, leading to demolition and rework.

Elevator Lobby Depth

If the elevator lobby is too small, people waiting will block the doorway and exits. This can slow down movement and cause safety problems. To avoid this, the lobby should be at least 1.50 m (5 ft) deep, and in public buildings at least 1.80 m (6 ft).

Passenger Elevator Dimensions

Passenger elevators are the most common type, used in residential, office, and commercial buildings. Their main role is to move people quickly and safely.

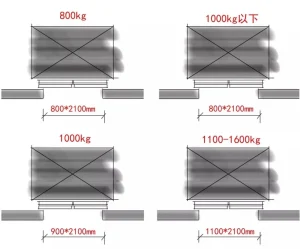

Passenger Elevator Cab and Shaft Dimensions

Passenger elevators are defined by their rated load, cab size, and shaft size. The cab must be large enough for passengers to stand comfortably, while the shaft must be larger to allow room for rails, counterweights, and clearances.

| Rated Load | Persons | Cab Size (W × D × H) | Floor Area | Shaft Size (W × D) |

|---|---|---|---|---|

| 630 kg | ~8 pers | 1.10 × 1.40 × 2.20 m | ~1.54 m² | ≈ 1.80 × 1.80 m |

| 1000 kg | ~13 pers | 1.60 × 1.40 × 2.20 m | ~2.24 m² | ≈ 2.15 × 2.20 m |

| 1600 kg | ~21 pers | 1.90 × 1.70 × 2.30 m | ~3.23 m² | ≈ 2.50 × 2.55 m |

-

Cab height: typically ≥ 2.1–2.3 m, per EN 81-20.

-

Floor area: must match load capacity (e.g., 0.125 m² per person).

-

Calculation formula: Shaft width = cab width + ~700 mm; Shaft depth = cab depth + ~600 mm.

Example:A 1000 kg passenger elevator has a cab of 1.60 × 1.40 m (~2.24 m²) and requires a shaft of about 2.15 × 2.20 m.

Accessible Elevator Dimensions

Accessible elevators are made for people who use wheelchairs, seniors, and others with limited mobility. They follow special rules such as ADA in the US and EN 81-70 in Europe. If these rules are not met, some people may not be able to use the elevator, and the building may not pass inspection.

General Dimension Requirements

| Configuration | Cab Size (m) | Shaft Size (m) |

|---|---|---|

| Wheelchair only | 1.40 × 1.10 | 2.00 × 1.60 |

| Wheelchair + attendant | 1.50 × 1.40 | 2.20 × 2.00 |

| Wheelchair + stretcher | 1.50 × 1.60 | 2.40 × 2.20 |

Load capacity: at least 630–1000 kg.

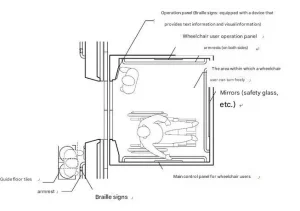

Accessibility Requirements

Elevators must have space for wheelchairs to move safely. A clear turning circle of 1.50 m (5 ft) in front of the door lets a wheelchair approach, align, and turn without trouble.

Doors also need to be wide enough. In new buildings, the clear width should be at least 0.90 m (3’0”). In older buildings or retrofits, 0.80 m (2’7”) may be accepted, but this makes it harder for larger wheelchairs or stretchers to pass through.

Control panels should be placed 0.85–1.10 m above the floor so they can be reached from a seated position. Buttons must have tactile and braille labels, and elevators should give both audio announcements and visual signals so people with vision or hearing limits can use them safely.

Firefighter Elevator Dimensions

A firefighter elevator is a special type of lift made for rescue work during a fire. It is built inside fire-resistant walls, has a separate lobby, and comes with backup power. In daily use, it works like a normal passenger elevator. But when a fire starts, it can switch to firefighter mode, allowing firefighters to carry their tools to higher floors and help people escape.

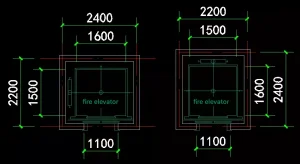

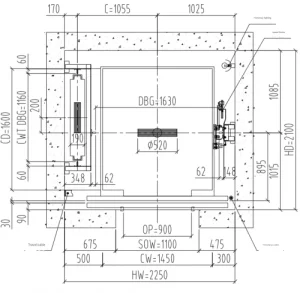

Cab and Shaft Dimensions

-

Cab size: minimum 1.50 × 1.60 m,The net width of the door opening is not less than 0.90m, load ≥ 800 kg. Many projects use larger cabs for easier crew access.

-

Shaft size: about 2.0 × 2.2 m minimum, depending on load.

Fire Lobbies (Protected Waiting Areas)

Many builders think only about the size of the elevator cab and forget the fire lobby. But without a safe waiting area, even a firefighter elevator cannot be used during a fire. This lobby protects the elevator from smoke and water so firefighters can work and people can escape.

Key dimension requirements:

-

Lobby area: at least 6 m²

-

Shortest side: at least 2.4 m

-

Location: close to an outer wall, with a direct outdoor exit no more than 30 m away

-

Door width: 0.90–1.20 m (wide enough for equipment and stretchers)

Extra features like thresholds or floor drains are also needed to keep water from entering the shaft.

Special Requirements

Elevator design is not only about size. Some fire safety features also take up space and must be planned early. The shaft needs fire-rated walls that can resist fire for at least two hours. These walls are thicker and make the inside space smaller. All wiring and panels should be waterproof, and the covers may need extra room. In the lobby, firefighter intercoms and control panels also need wall space so they can be reached quickly in an emergency. At the bottom of the shaft, a sump pit with drainage is required. It should hold at least 2 m³ of water and have pumps that can move 10 liters per second, which makes the pit deeper and wider.

These features are not extra add-ons. They change the size of the cab, shaft, walls, and pit, and must be included from the very start of the design.

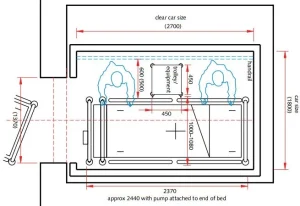

Hospital Elevator Dimensions

Hospital elevators are designed for hospitals and large care facilities. Unlike stretcher-accessible elevators, which are meant for emergencies in housing, hospital elevators are everyday workhorses for moving patients, beds, staff, and equipment.

General Dimension

-

Cab size: 1.40–1.60 m wide × 2.30–2.40 m deep.

-

Load capacity: 1600–2000 kg.

-

Doors: ≥ 1.20 m clear opening.

-

Shaft size: about 2.4 × 3.0 m for a 1600 kg unit.

Special Requirements

Hospital elevators need walls and floors that are easy to clean. Many use antimicrobial panels to help control infection.

They also need stainless steel rails for staff and wide doors so beds and equipment can move in and out without trouble.

The ride needs to be smooth with little shaking so patients are moved safely.

Finally, hospital elevators need large cabins with enough strength to carry a bed, two or three staff, and a medical cart at the same time.

Freight and Car Elevators Dimensions

Freight elevators move goods; car elevators move vehicles. They are not designed for people, though operators may ride with loads. These elevators must be stronger, larger, and safer for heavy cargo.

Freight Elevator (General Dimensions)

Load capacity: 1000–5000 kg common.

Cab sizes:

- 1000 kg → 1.40 × 1.60 m cab, shaft ≈ 2.3 × 2.2 m.

- 5000 kg → 2.40 × 3.55 m cab, shaft ≈ 3.56 × 4.15 m.

Special Requirements for Freight Elevators

Freight elevators need reinforced floors to carry heavy loads. They also use bump rails on the walls to protect both the cab and the goods. The elevators run at a slow speed so loading and unloading can be done safely. They also have wide doors so large items can move in and out without trouble.

Car Elevators (General Dimensions)

Load capacity: 3000–5000 kg.

Cab sizes:

- 3000 kg → 2.50 × 5.10 m cab, shaft ≈ 4.0 × 5.9 m.

- 5000 kg → 2.90 × 5.60 m cab, shaft ≈ 4.36 × 6.38 m.

- Doors: ≥ 2.40 m clear width.

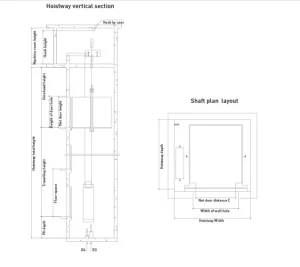

Planning Notes for Elevator Shaft Dimensions

When planning a building, the elevator shaft must be sized correctly from the start. Many problems in construction happen because the shaft was drawn too small, or finishing work was not considered. Once concrete is poured, mistakes are costly to fix.

The first thing to check is compliance with code. For example:

-

The clear cab height must be at least 2.0 m, so the shaft must allow enough space above.

-

The shaft opening should leave allowance for finishes. A common practice is to add +100 mm in width and +70–100 mm in height. Without this, after tiles or panels are installed, the net opening will be too small.

-

For accessible elevators, the shaft must allow a cab large enough for a wheelchair turning circle (1.50 m). Doors should have at least 0.90 m clear width in new buildings.

The second thing to check is structural vs finished dimensions. The shaft is built to structural size, but once walls and finishes are added, the net opening is smaller. If you only plan to the finished size, the elevator may not fit, leading to demolition and rework.

Here are common net door widths required by code:

Tip: Always confirm that the structural shaft size > finished shaft size > cab size. This way, when the finishes are applied, the net dimensions still meet code and the elevator can be installed smoothly.

Conclusion

Elevator dimensions is more than just numbers. It decides safety, ease of use, and code approval.

To get it right, architects and developers need to balance three things. First, follow the right codes like ADA, EN 81, IBC, and ASME. Second, think about the building type—homes, hospitals, warehouses, or tall towers all need different sizes. Third, use the manufacturer’s knowledge, such as shaft drawings, extra space for finishes, and custom solutions.

If the elevator is too small, it may fail inspection and be unsafe. If it is too big, it wastes shaft space and costs more to run. The best way is to plan early, so the cab and shaft sizes fit both the rules and the building’s real needs.

💡 Contact BDFUJI today for a custom elevator dimensions solution for your project.