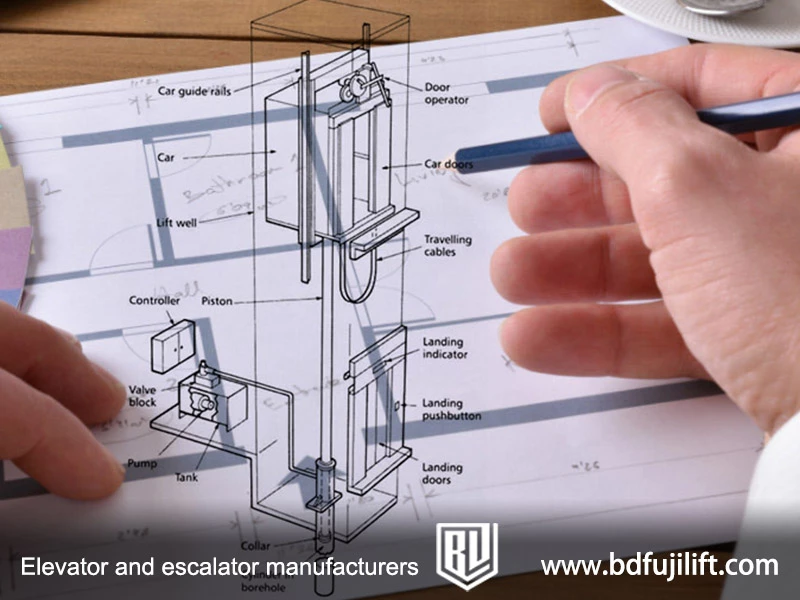

Elevators are a key part of most modern buildings. But when the design is not planned early, it can lead to big problems during construction. For example, the shaft may be too small, the pit too shallow, or the machine room in the wrong place. Fixing these problems later can cost a lot of time and money.

Good elevator design should start early and be part of the building’s structure and MEP (mechanical, electrical, and plumbing) planning. The elevator needs space, power, and smooth paths for cables and air. If these are not planned in time, it can delay the whole project.

In this guide, we will share simple tips to help you avoid common elevator design mistakes. From choosing the right type of elevator to making sure your shaft has the right size, these tips can help you keep your project on track.

1. Choose the Right Elevator Type for Your Building

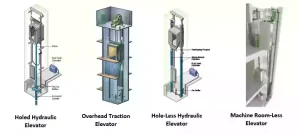

Every building has different needs. That’s why choosing the right elevator type is one of the most important steps in the design process. The type you choose depends on how the elevator will be used, who will ride it, and what space is available in your building.

Some elevators are made to carry people, while others carry heavy goods. Some need a machine room, and others don’t. Picking the wrong type can lead to serious problems — like not enough space, slower performance, or even failed inspections. So it’s best to decide early, based on the building’s purpose.

Elevators are often grouped into four main types:

| Elevator Type | Best For | Key Features |

|---|---|---|

| Passenger Elevator | Homes, offices, hotels, malls | Moves people; smooth, quiet, and easy to use |

| Cargo Elevator | Factories, warehouses | Moves goods; large, strong, slower speed |

| Hospital Elevator | Hospitals, medical buildings | Fits hospital beds; smooth ride, wide doors |

| Machine Room-Less (MRL) | Small buildings, modern designs | No machine room; saves space and energy |

Let’s say you are designing an office building. In that case, you’ll need a passenger elevator that moves people quickly, especially during busy hours. But in a hospital, a bed elevator is required by code so patients can be moved safely. And in a factory, a Cargo elevator is better for moving machines, boxes, or pallets.

Also, think about the machine room. Older elevators need a separate room to hold the motor and controller. Newer MRL (machine-room-less) elevators place those parts inside the shaft. This saves building space, but it also changes how you design the shaft and how much overhead and pit space you need.

So before choosing an elevator, ask:

-

What kind of people or goods will it carry?

-

How much weight and space will it need?

-

Does the building allow room for a machine room or not?

Making the right choice now will help avoid redesigns and construction delays later.

2. Define Shaft, Pit, and Overhead Requirements Clearly

Every elevator needs the right space to work safely and smoothly. This includes the shaft, the pit at the bottom, and the overhead space at the top. If these spaces are not planned correctly, the elevator may not fit — or worse, may not pass inspection. This is a common cause of delays and costly rework.

Different elevator types need different sizes. For example, a machine room-less (MRL) elevator needs more overhead space than a small home elevator. A freight elevator needs a wider and deeper shaft than a passenger one. So before choosing an elevator, it’s important to understand these size rules.

Here is a simple comparison:

| Elevator Type | Recommended Pit Depth | Recommended Overhead | Common Shaft Size (W × D) |

|---|---|---|---|

| Passenger (630 kg, 8 ppl) | 1200 mm | 4000 mm | 1800 × 1500 mm |

| Bed Elevator (1600 kg) | 1400 mm | 4500 mm | 2400 × 2700 mm |

| Freight Elevator (2000 kg) | 1500 mm | 5000 mm | 2600 × 3000 mm |

| MRL Elevator | 1300 mm | 4200–4700 mm | Varies by capacity |

Note: These are typical values and may change by brand or code. Always check the local elevator code like EN 81, ASME A17.1, or GB 7588.

Also, keep in mind construction tolerance. The shaft walls may not be perfect after building, so you should reserve extra space in the design. A good rule is to leave at least +25 mm on each side of the shaft. This helps the installer adjust the guide rails and door frames easily.

Key Tips:

-

Plan the shaft early with your elevator supplier’s layout drawings.

-

Confirm the pit and overhead before the structure is built.

-

Leave at least ±25 mm tolerance in shaft width and depth.

-

Make sure the pit floor is flat and waterproofed.

-

Always match elevator type with its space needs.

Clear space planning avoids trouble later — and keeps your project on time.

3. Allow Enough Installation Tolerance

Even if your elevator layout drawing looks perfect, the real building may not match it exactly. That’s why you must leave enough tolerance — or extra space — in your shaft design.

If the shaft is too tight, it becomes hard to install guide rails or landing doors. This can lead to extra cutting, drilling, or even remaking concrete walls, which costs time and money.

Key areas to check:

-

Shaft width and depth: Always leave at least +25 to +50 mm extra on each side compared to the elevator size. This space helps the installer align the car, doors, and guide rails correctly.

-

Diagonal difference: The shaft walls may not be square. If the diagonal length between opposite corners is too different, the elevator may tilt or run noisily. Try to keep the diagonal difference under 10 mm.

-

Vertical deviation: From bottom to top, the shaft walls can shift. If they are not straight, the guide rails may twist, causing vibration. Keep vertical error within 15 mm for typical buildings.

Why does it matter?

Imagine trying to fit a big cabinet into a narrow closet. Even if the sizes are close, a small misalignment will stop it from going in. It’s the same for elevators — they need room to breathe.

Simple Design Tips:

-

Ask your elevator supplier for a shaft layout drawing with tolerance lines.

-

Tell your civil engineer to reserve slightly more space than shown on the drawing.

-

Before elevator installation, ask for a shaft measurement check to avoid surprises.

Good tolerance planning = smooth installation + no costly changes later.

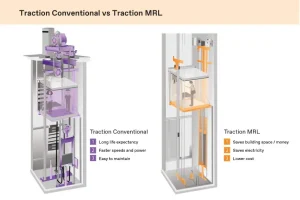

4. Coordinate Machine Room or Opt for MRL Properly

When choosing an elevator, one big decision is: Do you need a machine room (MR) or not?

There are two main types:

-

With machine room (MR): These elevators need a separate room above or beside the shaft to hold the motor and control panel.

-

Machine-room-less (MRL): These elevators place the motor inside the shaft itself, saving building space.

What’s the difference?

| Type | Needs extra space? | Easy to maintain? | Used in |

|---|---|---|---|

| MR | Yes (above shaft) | Easier | High-rise buildings, hospitals |

| MRL | No | Harder (less access) | Small buildings, residential |

Common mistakes with MRLs

MRL elevators are space-saving, but you still need enough space in other areas:

-

Pit depth: The space under the elevator car must be deep enough for safety parts like buffers. Too shallow? The elevator can’t pass inspection.

-

Overhead space: You need enough height above the top floor for the car to stop safely. If not, you may have to lower the ceiling or use a smaller elevator.

Tips to get it right:

-

Ask your elevator supplier for the exact space requirements before you build.

-

Don’t just assume “MRL = zero extra space.” You still need to plan carefully.

-

For high-traffic or tall buildings, a traditional MR elevator may still be better.

Planning the right system helps avoid costly rework and keeps your project on schedule.

5. Collaborate Early with Structural and MEP Teams

Elevator installation is not a job that happens alone. It must work well with the building’s structure, electrical, and plumbing systems. If you don’t plan together early, problems will show up during installation.

Reserve space for embedded parts

Elevators need steel brackets and guide rail supports to be built into the concrete walls. These are called embedded parts. If the builder forgets to place them early, it’s very hard to fix later. Workers may need to break the wall and redo concrete, causing delays.

Plan where pipes and wires go

Many buildings have MEP systems (Mechanical, Electrical, Plumbing) that pass through elevator shaft walls. If you don’t check early:

-

A pipe might block the elevator rails.

-

A cable tray might go where the controller box should be.

-

Or a fire pipe might go through the elevator door area.

All these cause rework and safety issues.

Coordinate the sequence of work

Elevator installation happens in stages: first comes the rails and brackets, then the car, then the decoration.

But if the wall is not finished or wires are not ready, the elevator team cannot continue. Worse, if another trade (like HVAC or ceiling works) overlaps with elevator work, it slows everyone down.

6. Avoid Abrupt Structural Transitions

Inside the elevator shaft, the floor and wall surfaces must be smooth and level. Uneven areas like sudden steps, bumps, or sloped beams can cause big problems later during installation.

For example, if the bottom of the shaft is not flat, the buffer may not sit evenly. This can make the elevator unsafe. Also, if the guide rail base tilts due to an uneven floor, the whole rail can go out of alignment — which may cause noise, shaking, or even safety risks.

Here are some tips:

-

Keep the pit floor level within 5 mm from side to side.

-

Avoid sudden changes in height — if needed, use a gentle slope or create a step with flat support.

-

If there is a beam, make sure the buffer has a flat surface to rest on.

-

Check drawings carefully before concrete work, especially in the pit area.

Getting the base structure right helps your elevator run smoothly and safely from day one — and avoids costly rework.

7. Plan Door Opening Space and Fixing Zones

Elevator doors need enough space to open and close safely. If the space is too small, the door might not open fully, or parts may hit the wall or frame.

Make sure the shaft opening is wide enough for the type of door you use. Most standard doors need at least 800 mm to 1,100 mm of clear space. Also, reserve a strong beam above the opening (called the header beam) so the door tracks and motors can be mounted firmly.

If you’re using special doors, like full glass doors, plan even more carefully. Glass doors often need extra support to keep them safe and stable. You may need to leave space for hidden brackets or extra fixing parts behind the wall.

In some buildings, there is a small elevator lobby or fire-rated front room. Be sure to leave room for the door to open without hitting walls, sprinklers, or pipes. Plan all these spaces early so you don’t need to redo any construction later.

8. Ensure Maintenance and Accessibility Clearances

Elevators need safe and easy access for future checks and repairs. If you don’t leave enough space, it becomes hard — or even dangerous — to fix parts later.

Some key areas that need space include:

-

Control cabinet (for wiring and settings)

-

Buffer at the bottom of the shaft (for stopping the car safely)

-

Governor and overspeed device (usually near the top)

-

Inspection openings (for checking the shaft or car top)

Make sure these parts are not blocked by walls, pipes, or decoration. Also, never place tiles, ceilings, or glass in a way that covers access panels.

Always leave a safe zone for technicians to stand, open tools, and operate safely. If you plan this early, you avoid breaking walls or removing finishes later — and keep your elevator service-friendly for years to come.

9. Follow Local Elevator Codes and Safety Standards

Every country has its own rules for how elevators must be built. These rules are called elevator codes, and they help keep people safe.

Some common codes include:

-

EN 81-20 / 81-50 – used in Europe

-

ASME A17.1 – used in the United States and Canada

-

GB 7588 – used in China

These codes tell you important things like:

-

How big the shaft must be

-

How much space is needed for rescue and safety

-

How far parts like rails and walls should be apart

-

Where to put doors, emergency exits, and lights

If your design doesn’t follow the local code, you may have to rebuild parts of your shaft later — which can be very costly and delay your project.

Before you build, check the local rules or ask your elevator supplier for help. A safe, code-compliant design keeps your project on track and ready for inspection.

Conclusion

Every small detail in elevator design can affect your project’s cost and timeline. If something is missed, it may lead to delays or expensive rework.

That’s why it’s important to plan early and talk with all teams — structure, MEP, and elevator — before building starts. Good communication helps avoid problems and keeps your project moving forward.

Need Help?

📩 Contact us today for a free review of your elevator drawings. We’ll help you find issues early — before they become costly mistakes.