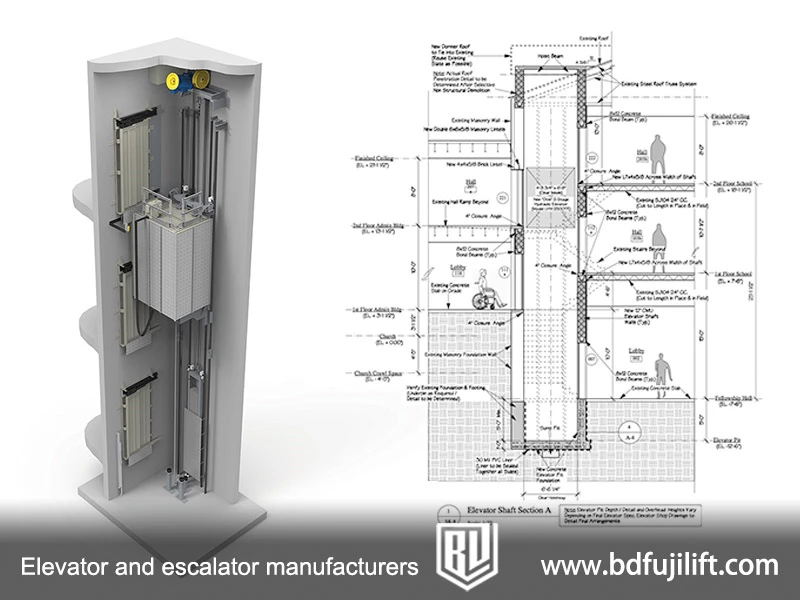

Elevator shafts must be carefully designed to match the elevator’s size and layout. But in real projects, small errors in shaft dimensions can lead to costly rework, delays, or even redesigns.

To help builders, engineers, and architects avoid these problems, we’ve created a clear guide based on real elevator standards and cases. This article explains how to design shaft dimensions correctly from the start—and how to fix issues if they happen.

Read on to learn about:

-

Why elevator shaft design mistakes are common

-

The most frequent error points like pit depth and doorway width

-

A comparison of size requirements for different elevator types

-

Real project examples of how to handle mismatched sizes

-

A simplified take on dimension tolerance (inspired by GD&T ideas)

-

A free downloadable standard shaft drawing template

Why Is It Easy to Make Mistakes in Elevator Shaft Design?

Designing an elevator shaft looks simple, but it’s easy to get wrong. If just one measurement is off, the elevator might not fit. Fixing these mistakes later can cost a lot of time and money.

One big reason for mistakes is that many people work on the building. Architects, engineers, and elevator companies all make their own drawings. If they don’t share the same details, the final size of the shaft may be wrong.

Another problem is guessing. Sometimes, builders start without knowing which elevator will be used. They guess the size and hope it works—but that’s risky. Different elevators need different shaft sizes.

Things can also change during construction. Workers may move a wall or change the floor height. Even small changes can make the shaft too small for the elevator.

That’s why it’s important to check the elevator needs first and make sure all teams use the same plan from the beginning.

Common Error Locations

Elevator shaft mistakes often happen in a few key places. These small errors can stop the elevator from fitting or working correctly. The most common problem areas are:

Doorway Net Width

This is the clear opening space for the elevator doors. If it’s too narrow, the elevator doors can’t open fully. If it’s too wide, there may be safety gaps or problems with door sensors. Even a 10 mm error here can cause delays or need special adjustments. This is one of the first things checked during installation.

Pit Depth

The pit is the space under the lowest floor, where elevator parts like buffers are placed. If it’s too shallow, safety devices won’t fit. If it’s too deep, the guide rails may need custom extensions. Pit depth must match the elevator’s speed, type, and load. It’s a hidden problem until installation begins—and by then, it’s hard to fix.

Shaft Diagonal Deviation

This refers to how square the shaft is across its diagonals. If the diagonals don’t match, the shaft is not a true rectangle. This can cause the cabin to scrape, vibrate, or fail safety tests. Diagonal errors often come from poor formwork or wall misalignment. Checking diagonals early can prevent a lot of rework later.

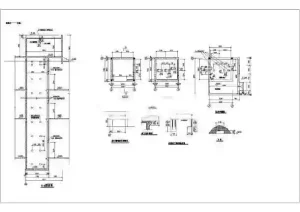

Comparison Table of Dimension Requirements for Different Elevator Types

This table lists key dimension requirements for different elevator types. These values are general guidelines and may vary by brand or model. Always confirm with your elevator supplier’s technical drawings.

| Elevator Type | Typical Door Opening (W x H) | Min. Pit Depth | Min. Overhead Height | Notes |

|---|---|---|---|---|

| Passenger Elevator | 800–1100 mm x 2000 mm | 1200 mm | 3500 mm | Common in homes and offices |

| Freight Elevator (A Type) | 1500 mm x 2100 mm | 1500 mm | 4200 mm | For general goods, light vehicles |

| Freight Elevator (C1) | 2000 mm x 2200 mm | 1600 mm | 4500 mm | Designed for forklift entry |

| Car Elevator | 2500 mm x 2000 mm | 1800 mm | 5000 mm | For full-size cars in showrooms or garages |

| Hospital/Bed Elevator | 1100 mm x 2100 mm | 1300 mm | 4000 mm | Supports stretchers or hospital beds |

| MRL (Machine Room-Less) | 800–1000 mm x 2000 mm | 1000 mm | 3200 mm | Requires less space, compact design |

Key Definitions:

-

Door Opening: Clear width and height when doors are fully open

-

Pit Depth: Distance from finished floor to shaft bottom

-

Overhead Height: Space from top landing floor to top of shaft

What to Do if the Elevator Shaft Dimensions Don’t Match? Real Project Example

In one project, a builder planned to install a machine-room-less elevator in a small office building. He started building the shaft early, using old drawings from a past project. He did not check the new elevator’s real size.

When our BDFUJI team arrived to install the elevator, we found several problems. The doorway was 50 mm too narrow, so the doors could not open fully. The pit was only 1000 mm deep, but our elevator needed 1300 mm for the safety buffers. Also, when we checked the shaft diagonals, one side was 25 mm longer than the other. This made the elevator car rub against the rails.

We stopped the work and used a laser scanner to check the shaft size and shape. The scan showed the full problem. Based on our technical drawings, we guided the builder to fix it:

-

They broke part of the pit and rebuilt it 300 mm deeper

-

They cut the wall and added a new frame to widen the doorway

-

They added steel to make the shaft walls straight and square

After the changes, we installed the elevator, and it passed all safety checks.

Lesson learned: Always use the latest elevator drawings before building the shaft. Check the doorway, pit, overhead space, and shaft diagonals. At BDFUJI, we’re always ready to help catch and fix problems early—so your project stays on track.

Recommended Elevator Shaft Dimension Tolerance Range

Good elevator shaft design needs the right size—but also the right tolerance, or “wiggle room.” The building does not need to be perfect, but it must be close enough for the elevator to fit and work safely. Here are simple tips to follow:

-

Always check the elevator specs first. Use the latest drawing from the elevator company, not an old one.

-

Door opening width can be off by ±10 mm. More than that may stop the doors from opening smoothly.

-

Pit depth can have a tolerance of ±20 mm. If it’s too shallow, safety parts may not fit.

-

Overhead space should allow ±30 mm. This helps with top-floor clearance and travel.

-

Shaft walls must be straight. Try to keep the diagonal error under 15 mm.

-

Leave extra room if you are unsure—making space is easier than fixing walls later.

-

Keep drawings clean and clear. Don’t crowd dimensions. Use simple notes and show all key sizes.

These small limits help the elevator fit without trouble. They also make work faster and safer for the team.